As part of digitization efforts, many companies are implementing technologies or processes into production that are often groundbreaking for them. To minimize risks before implementation and enhance efficiency, even in relation to processes that are already known, simulation-based system and machine planning are increasingly employed. MathWorks and Bosch Rexroth have joined forces in the field of simulation and automation, supporting, for example, the simplified creation of digital twins.

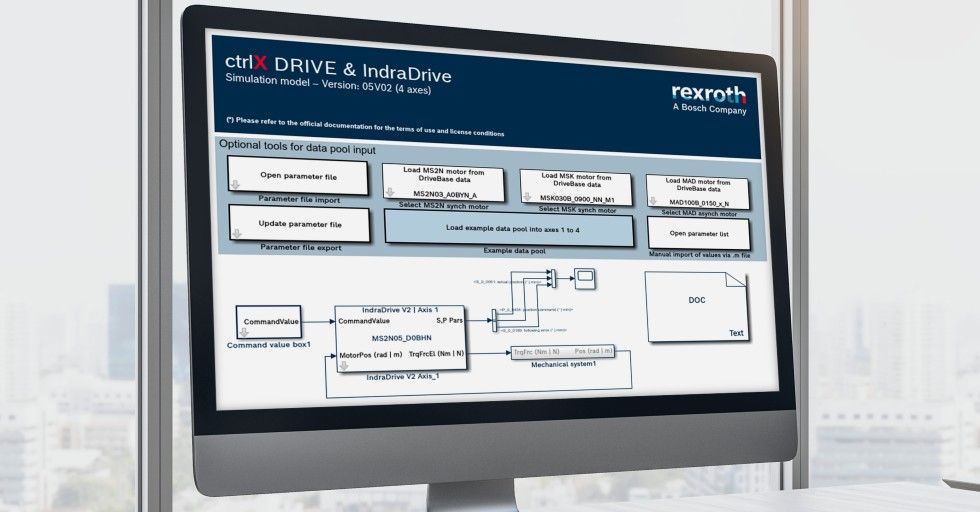

MathWorks is the creator of mathematical computation software utilizing the MATLAB platform and the block diagram environment Simulink. It is a high-level language and interactive environment that can be used for rapid execution of tasks requiring intensive calculations. Simulink complements this product as modeling software. Both solutions find applications in various fields, such as machine and system engineering or even in the development of automation components. Now, they can be integrated with the ctrlX AUTOMATION automation toolkit.

Machine models can be directly created in MATLAB and Simulink. Through a simulation connection with ctrlX AUTOMATION, the resulting program code can be executed in real-time on the ctrlX CORE control platform. Model-based development allows for the verification of digital solutions created in MATLAB and Simulink in the early simulation stage, followed by their transfer to the automation platform using code generation functions. Data can also be returned to the simulation system in real-time to improve the model during simulation.

“Thanks to the direct connection between simulation and automation platforms, users save a lot of time as they can virtually test the machine or system model before finalization. This way, we first deal with a digital twin of the machine before it is configured by the manufacturer. This enables us to detect and eliminate errors in advance, optimize processes, and more,” explains Hans Michael Krause, Head of Product Management ctrlX World at Bosch Rexroth.

“Furthermore, the joint solution, in addition to virtual commissioning options, lays the foundation for the development of AI-based solutions, such as for predictive maintenance,” adds Norbert Ulshöfer, Director of the Application Engineering Team at the German branch of MathWorks.

The complete solution emphasizes the concept of the ctrlX AUTOMATION system: an open automation platform with application technology and an ecosystem that blurs the traditional boundaries between machine control, IT, and the Internet of Things, thus shedding new light on co-creation capabilities.

Illustraion: Bosch Rexroth

![Forecasts, Opportunities, and Challenges for the Polish Industry in 2024 [ANALYSIS] Forecasts, Opportunities, and Challenges for the Polish Industry in 2024 [ANALYSIS]](https://industryinsider.eu/wp-content/uploads/xIndustry-40-320x167.jpg.pagespeed.ic.o8zijDQlIJ.jpg)

![The importance of artificial intelligence in transport and automotive industry is growing [REPORT] The importance of artificial intelligence in transport and automotive industry is growing [REPORT]](https://industryinsider.eu/wp-content/uploads/xcity-320x167.jpeg.pagespeed.ic.xFkQdk7qXO.jpg)

![By 2030, the market size of metal processing tools is expected to reach $120.44 billion [REPORT] By 2030, the market size of metal processing tools is expected to reach $120.44 billion [REPORT]](https://industryinsider.eu/wp-content/uploads/xcutting-tools-320x167.jpg.pagespeed.ic.SgnEk-RWA-.jpg)

![Methane emissions remains elusive challenge for oil and gas industry [REPORT] Methane emissions remains elusive challenge for oil and gas industry [REPORT]](https://industryinsider.eu/wp-content/uploads/xMethane-emissions-by-source-320x167.jpg.pagespeed.ic.q-7jG2luXb.jpg)

![Will digital twin revolutionize the aerospace and defense sector? [REPORT] Will digital twin revolutionize the aerospace and defense sector? [REPORT]](https://industryinsider.eu/wp-content/uploads/xdigital-twin-in-aerospace-320x167.jpg.pagespeed.ic.K-YNPhggcS.jpg)