According to many experts, there is a high probability that the Polish industry will return to a growth trajectory this year.

- Can we expect increased investments and a rebound in domestic consumption?

- What steps should be taken to ensure efficient, safe, and sustainable deliveries in the coming months?

- How can Industry 4.0 solutions support the industry’s return to the right track?

According to S&P Global data, the Purchasing Managers’ Index (PMI) measuring the opinions of purchasing managers in 200 Polish industrial firms rose to 48.7 points in November 2023, compared to 44.5 points in October.

However, there was a slight decrease in the index to 47.4 points in December, which is still much better than economists’ earlier forecasts, predicting an improvement only to 45.3 points. These values are the highest since April 2022 when the index reached over 52 points.

In the following months, there was a decline due to economic slowdown, rising interest rates, inflation, and concerns related to the war in Ukraine. Nevertheless, on a quarterly basis, the PMI for the fourth quarter averaged 46.9 points, which was higher than in the second and third quarters of the year.

Does this mean that the industry may start feeling relief, and managers can look to the future with optimism?

“It seems that in the first months of the new year, we can still expect a decline in production in the Polish industry,” commented Mariusz Zielonka, an economic expert at the Confederation Lewiatan. However, Polish industrial companies hope that despite everything, domestic consumption will pick up again in 2024. Analysts also cautiously predict that despite recent negative data, the Polish economy will return to a growth trajectory, mainly due to domestic consumption.

With a stable geopolitical situation, it is expected that the growth of the Polish GDP in 2024 will hover around 2.4-2.8%. According to experts, the main driver of growth will be the injection of funds from the National Reconstruction Plan, which will fuel a significant increase in investments and the expected recovery in domestic consumption.

Industry 4.0: Digital Transformation on the Rising Wave

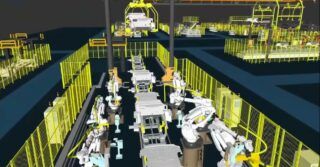

Regardless of the direction of changes, a revolution in the industry is happening before our eyes, significantly impacting the shape of industrial production in the near future. This revolution is shaped by Industry 4.0 solutions, which help make production more efficient, innovative, and provide support for processes that particularly require attention. Manufacturing facilities have at their disposal a range of technologies and strategies aimed at improving production, management, supply chains, customer service, and other areas related to the industry.

Internet of Things (IoT) solutions help leverage sensors, monitors, and internet-connected devices to better monitor processes. The implementation of industrial robots, mobile robotics, and production process automation systems allows for increased efficiency, cost reduction, and improved quality.

Machine learning algorithms and artificial intelligence bring production closer to process optimization, equipment failure prediction, production personalization, etc. Not to mention solutions in the Digital Manufacturing domain during the design, prototyping, and production process, such as 3D printing, computer simulations, virtual reality (VR), or complete industrial platforms that integrate various systems, data, and processes within a single ecosystem facilitating collaboration and information exchange among different supply chain participants.

As Aleksandra Banaś, the CEO of ifm electronic, a company producing sensors and systems for process automation, emphasizes, “Industry 4.0 solutions provide us with entirely new possibilities that we need to embrace. Only adequately digitized supply chains will guarantee efficient, safe, and sustainable deliveries and enable the achievement of ambitious goals set for 2024.”

Revolution or Evolution in Industrial Automation?

In December 2023, we witnessed the twenty-second consecutive monthly decline in the volume of new orders received by Polish manufacturers. Improvement is possible, but it is not certain.

“Polish manufacturers should double their efforts to attract buyers while simultaneously limiting production costs and optimizing manufacturing processes. There is no other way than industrial automation. It may seem that the time for investments is not good enough, but if our competition improves its production efficiency and, consequently, its offerings, we may lose orders in the fierce competition. As a supplier of sensors and communication and control systems, we see how interest in more complex, holistic solutions increases from year to year,” comments Aleksandra Banaś.

Industry Towards Ecology

A study by SEC Negwate ESG Monitor showed that nearly 7 out of 10 consumers worldwide (68%) agree that companies should more transparently inform consumers and investors about the results of their sustainable development activities. Reporting on the impact of business activities on the planet is increasingly not only a legal obligation but also a necessary condition to meet the expectations of customers, contractors, and investors.

Considering ESG (Environmental, Social, and Governance) factors in the assessment of a company or investment concerns an increasing number of organizations. This is due to the CSRD Directive, which is one of the foundations of the European Green Deal and sustainable financing program. It imposes a non-financial reporting obligation for the year 2024 on companies employing over 500 people and meeting the revenue criterion. Non-financial reporting for the fiscal year 2025 will be mandatory for companies employing over 250 people, and the following year for most small and medium-sized enterprises.

As Aleksandra Banaś notes, “we should already include issues related to environmental protection in our daily decisions and actions. In ifm, goals are clearly defined, including achieving climate neutrality by 2030 in all operational activities, long-term CO2 savings in business travel and commuting, and applying a 100% code of conduct for our suppliers.”

In May 2023, the first green ifm factory was opened in Sibiu, Romania. The new ifm factory uses photovoltaic modules to generate electricity, and heat demand is covered by heat pumps. “This facility is to set sustainable, ecological, economic, and socio-cultural standards,” adds the CEO of ifm electronic.

Cybersecurity in the Era of Industry 4.0

Industry 4.0 is based on the integration of modern information and communication technologies, the Internet of Things (IoT), artificial intelligence (AI), and other innovative solutions, making production systems more advanced but also more vulnerable to cyber-attacks. The introduction of many interconnected devices, machines, and computer systems increases potential attack vectors. Effective management of these complex networks is necessary to minimize the risk.

IoT devices, such as sensors, controllers, or automation elements, represent potential attack points. This requires securing each of these devices and ensuring secure communication between them. The same applies to the implementation of machine learning algorithms, especially in decision-making systems. It requires protection against attacks that can manipulate learning data.

As Aleksandra Banaś emphasizes, “attacks can focus not only on production itself but also on suppliers and business partners. Properly securing the supply chain is crucial for maintaining cybersecurity. One of the most important elements of the security system is people. Training and increasing the awareness of employees about cyber threats in automated industrial systems are key to minimizing the risk resulting from unconscious actions. In today’s industrial environment, where digital technologies play a crucial role, cybersecurity is an integral part of the business strategy. Industry 4.0 brings new challenges but also necessitates the development of advanced security solutions to maintain the integrity, availability, and confidentiality of data and production systems.”

According to the IBM X-Force Threat Intelligence Index 2023 report, the industry is currently the most common target of cyber-attacks. About 30% of all ransom-related attacks are conducted on industrial companies, with their number increasing by up to 300% annually. In the era of Industry 4.0, a key element of protection against unauthorized access and ransom attacks is full control of access to both physical and virtual systems. Monitoring systems should detect abnormalities and suspicious activities in real-time, enabling a quick response to potential threats.

Regular software updates, including security patches, are necessary to ensure that systems are properly protected. All of this—when entrusted to trusted and properly trained employees—will ensure that they operate without any unwanted disruptions

Moderately Positive Forecasts

Undoubtedly, the Polish industry enters 2024 in less than optimal condition. Despite moderately positive forecasts for the improvement of the situation in the second half of 2024, any predictions at this moment seem like fortune-telling—especially in the face of such significant uncertainty that all supply chain participants must contend with. Certainly, 2024 will not be easy, nor will it be easier than previous years.

Prepare for a struggle for liquidity, orders, and socially responsible development, but also for production that is increasingly digitized, automated, and digitally secure. Tools that are used correctly may be the key to success.

![Forecasts, Opportunities, and Challenges for the Polish Industry in 2024 [ANALYSIS] Forecasts, Opportunities, and Challenges for the Polish Industry in 2024 [ANALYSIS]](https://industryinsider.eu/wp-content/uploads/xIndustry-40-980x512.jpg.pagespeed.ic.DolUAn90My.jpg)

![The importance of artificial intelligence in transport and automotive industry is growing [REPORT] The importance of artificial intelligence in transport and automotive industry is growing [REPORT]](https://industryinsider.eu/wp-content/uploads/xcity-320x167.jpeg.pagespeed.ic.xFkQdk7qXO.jpg)