The size of the global metal cutting tools market was valued at USD 76.05 billion in 2022. According to forecasts, it is expected to reach USD 120.44 billion by 2030. Experts believe that during the forecast period (2023-2030), the Compound Annual Growth Rate (CAGR) for the global metal cutting tools market will be 6.2%.

In its report titled “Metal Cutting Tools Market, 2023-2030” Fortune Business Insights™ indicates that the market will gain popularity due to increasing demand from the automotive and aerospace industries, technological advancements, and the growth of metal production-related activities.

The growing use of CNC machines, a focus on precision engineering, and the demand for efficient metal processing solutions will be the driving forces behind the dynamics of this market.

Industrial automation has become a catalyst for change in manufacturing plants, significantly boosting the demand for smart manufacturing technologies.

Industry 4.0 has gained immense popularity in recent years, as it can help manufacturers reduce operating costs, effectively use energy, and enhance human-machine collaboration. The implementation of Industry 4.0 solutions has initiated a process where ensuring high quality during the production stage is desirable, thereby increasing the demand for metal cutting tools.

The report also points out that high initial investments and fluctuating raw material prices may hinder the development of this market.

Metal processing tools market: opportunities

Opportunities in the metal cutting tools market arise from the growing manufacturing activities, advancements in CNC machining, and the demand for precision tools in the aerospace and automotive sectors. The year-over-year growth in the renewable energy market and the adoption of Industry 4.0 principles provide consistent growth opportunities.

Strategic collaborations, product innovations, and addressing the changing needs of the industry can further enhance market share in this highly competitive field.

Metal processing tools market: challenges

Challenges facing the market for metal cutting tools include the impact of fluctuations in raw material prices on production costs, increasing competition, and the need for continuous technological progress. Economic uncertainty and stringent environmental protection regulations can be additional impediments contributing to a slowdown in the pace of development.

Overcoming these challenges requires strategic cost management, sustainable practices, and continuous innovation to maintain competitiveness in this dynamic and evolving market.

How is the metal cutting tools market segmented?

Depending on the type of production, the market for metal cutting tools is divided into machines such as machining centers, lathes, boring machines, grinders, milling machines, and others.

The report predicts that the machine tools segment will be the fastest-growing segment in the market due to the increasing demand for such machines from the automotive industry.

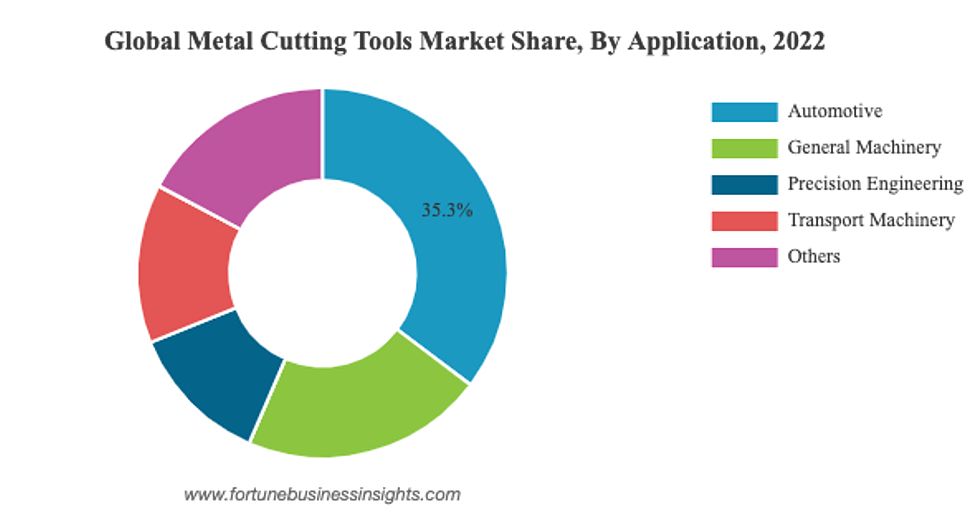

Due to the application of tools, the market is divided into the automotive industry, machinery, precision engineering, and others. The automotive segment has generated significant revenue recently. The need for manufacturing complex automotive parts for modern high-class vehicles is one of the key factors driving the market during the forecast period.

Metal cutting machinery market

The Asia-Pacific region has gained a significant share in the metal processing tools market, and it is expected to maintain its dominant position in the forecast period. This is attributed to the growing demand from sectors such as automotive and construction. Government initiatives aimed at promoting the sale of electric vehicles are expected to further accelerate the development of the automotive market.

China has reduced investments in new factories producing conventional vehicles, and local authorities have provided subsidies for the production of electric vehicles for all manufacturers.

In Europe, Germany recorded the highest revenues in 2022, and it is expected to continue this trend in the forecasted timeframe due to the expanding industrial and manufacturing sectors.

Key market players such as Doosan and Okuma plan to introduce new innovative products to the market in the coming years. The report also indicates that the growing number of machinery manufacturers in this industry is increasing competition in the global market. Therefore, many significant firms in the market are focusing on improving their performance and efficiency.

Key machinery manufacturers in the global market, according to the report:

- Yamazaki Mazak

- Doosan Machine Tools

- Trumpf

- Amada Machine Tools

- JTEKT

- Okuma

- Hyundai WIA

- FANUC America

- Komatsu

- Makino

![By 2030, the market size of metal processing tools is expected to reach $120.44 billion [REPORT] By 2030, the market size of metal processing tools is expected to reach $120.44 billion [REPORT]](https://industryinsider.eu/wp-content/uploads/xcutting-tools-980x512.jpg.pagespeed.ic.O-KJ1pxYHj.jpg)

![Forecasts, Opportunities, and Challenges for the Polish Industry in 2024 [ANALYSIS] Forecasts, Opportunities, and Challenges for the Polish Industry in 2024 [ANALYSIS]](https://industryinsider.eu/wp-content/uploads/xIndustry-40-320x167.jpg.pagespeed.ic.o8zijDQlIJ.jpg)

![The importance of artificial intelligence in transport and automotive industry is growing [REPORT] The importance of artificial intelligence in transport and automotive industry is growing [REPORT]](https://industryinsider.eu/wp-content/uploads/xcity-320x167.jpeg.pagespeed.ic.xFkQdk7qXO.jpg)