The device created by SYGNIS marks a breakthrough in the automation of the production of photonic nanostructured components. According to the company – the developed 3D Direct Ink Wrinting technology, with a dedicated 3D printer, allows to automate the process of creating preforms by directly extruding molten glass according to a programmed pattern.

It creates opportunities for applications not previously available, including in industries such as laser communication between satellites and the earth in harsh atmospheric conditions, laser skin therapies, real-time diagnosis with special imaging tubes or advanced components for research into the development of other photonic products/technologies.

As Sygnis points out – the device created makes it possible to replace six industrial machines and the production of one preform is at least ten times faster. The next step, in order to be even more efficient and to achieve hitherto unavailable beamforming properties, will be to harness generative artificial intelligence algorithms to design structures.

Currently, the company, through Syglass, is preparing to go to market with the product and to expand into overseas markets.

“Syglass is one of our flagship technologies that we are developing rapidly this year. The experienced Syglass team is perfectly positioned for the months ahead, including the US market, which is characterised by a huge demand for innovative additive technologies and a high adoption rate of new technologies. Based on our experience with existing customers and partners in the US, we have set ourselves specific goals, including expanding our network of partnerships with institutions and companies, expanding our advisory board and converting our first US customer to create a pilot product based on Syglass technology. ‘I believe that the high quality of our technology combined with the business competence of our team will allow us to strengthen our presence in the US, first and foremost precisely through our activities in Nevada and California,’ notes Dr Olga Czerwinska, CSO and vice-president of the management board of Sygnis SA.

The development of additive technologies and related materials in recent years has led to a significant increase in cost-effectiveness and applicability in industry. Rapid prototyping and the use of new and more efficient materials are bringing beneficial changes to specific industries such as aerospace, automotive, defence, energy and medical, among others, which is evident in processes, supply chains, maintenance or spare parts management.

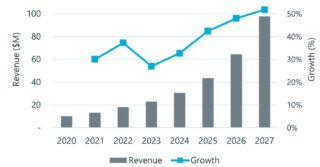

The global laser satellite communication systems market size was USD 618.2 million in 2021. The market is estimated to reach USD 39213.36 million in 2031, representing a CAGR of 40.56% during the forecast period.

![Forecasts, Opportunities, and Challenges for the Polish Industry in 2024 [ANALYSIS] Forecasts, Opportunities, and Challenges for the Polish Industry in 2024 [ANALYSIS]](https://industryinsider.eu/wp-content/uploads/xIndustry-40-320x167.jpg.pagespeed.ic.o8zijDQlIJ.jpg)

![The importance of artificial intelligence in transport and automotive industry is growing [REPORT] The importance of artificial intelligence in transport and automotive industry is growing [REPORT]](https://industryinsider.eu/wp-content/uploads/xcity-320x167.jpeg.pagespeed.ic.xFkQdk7qXO.jpg)

![By 2030, the market size of metal processing tools is expected to reach $120.44 billion [REPORT] By 2030, the market size of metal processing tools is expected to reach $120.44 billion [REPORT]](https://industryinsider.eu/wp-content/uploads/xcutting-tools-320x167.jpg.pagespeed.ic.SgnEk-RWA-.jpg)

![Methane emissions remains elusive challenge for oil and gas industry [REPORT] Methane emissions remains elusive challenge for oil and gas industry [REPORT]](https://industryinsider.eu/wp-content/uploads/xMethane-emissions-by-source-320x167.jpg.pagespeed.ic.q-7jG2luXb.jpg)

![Will digital twin revolutionize the aerospace and defense sector? [REPORT] Will digital twin revolutionize the aerospace and defense sector? [REPORT]](https://industryinsider.eu/wp-content/uploads/xdigital-twin-in-aerospace-320x167.jpg.pagespeed.ic.K-YNPhggcS.jpg)