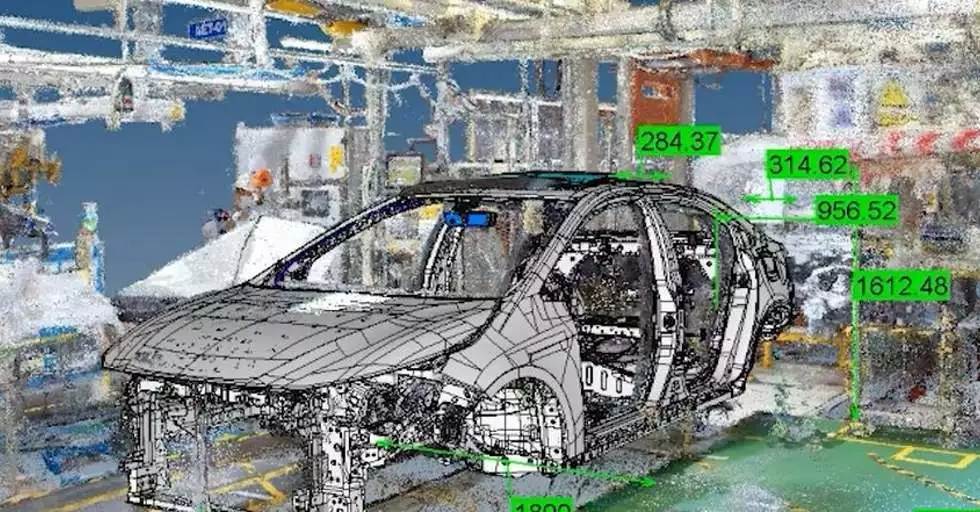

Toyota is introducing digital twin technology as another innovative step to increase the efficiency of car production and prepare for the launch of the new generation of vehicles. The company has announced the use of innovative casting techniques for building car bodies and the implementation of autonomous technology on production lines. Combining these innovations with work on digital 3D models will accelerate the process of eliminating potential production errors before actual production begins.

“With Digital Twin technology, rapid decisions can be made based on current knowledge of the environment, processes, equipment, and the layout of production lines. Shortening the time needed to start production is a breakthrough achievement,” says Kevin Potter, Vehicle Production Engineering Technician.

Digital twins, by enabling the simulation and optimization of production processes, contribute to increasing the ergonomics and safety of car assembly. Importantly, all introduced innovations to the production environment can be tested without the need for physical changes in the factory. This makes it easy to check, for example, whether a device used in Japan will be equally effective in a production facility in Turkey.

The introduction of new car models into production at the Toyota Motor Manufacturing Turkey factory using digital twin technology has allowed the company to optimize the preparation process while reducing the need for engineers to be present on-site.

Digital twin technology also involves support for conducting so-called alternative scenarios. Through them, Toyota can simulate the impact of introduced changes that production systems are to undergo, without compromising safety and maintaining the highest quality.

“Direct access to the virtual environment of production plants has significantly improved our information exchange capabilities. Thanks to Digital Twin technology, we started to understand each production plant faster, along with the dynamics associated with it, from the early stages of the project to the final production of the vehicle. This makes it easier for us to introduce innovations and anticipate technical challenges,” says Kevin Anderson, Senior Manager.

Illustration: Toyota

![Forecasts, Opportunities, and Challenges for the Polish Industry in 2024 [ANALYSIS] Forecasts, Opportunities, and Challenges for the Polish Industry in 2024 [ANALYSIS]](https://industryinsider.eu/wp-content/uploads/xIndustry-40-320x167.jpg.pagespeed.ic.o8zijDQlIJ.jpg)

![The importance of artificial intelligence in transport and automotive industry is growing [REPORT] The importance of artificial intelligence in transport and automotive industry is growing [REPORT]](https://industryinsider.eu/wp-content/uploads/xcity-320x167.jpeg.pagespeed.ic.xFkQdk7qXO.jpg)

![By 2030, the market size of metal processing tools is expected to reach $120.44 billion [REPORT] By 2030, the market size of metal processing tools is expected to reach $120.44 billion [REPORT]](https://industryinsider.eu/wp-content/uploads/xcutting-tools-320x167.jpg.pagespeed.ic.SgnEk-RWA-.jpg)

![Methane emissions remains elusive challenge for oil and gas industry [REPORT] Methane emissions remains elusive challenge for oil and gas industry [REPORT]](https://industryinsider.eu/wp-content/uploads/xMethane-emissions-by-source-320x167.jpg.pagespeed.ic.q-7jG2luXb.jpg)

![Will digital twin revolutionize the aerospace and defense sector? [REPORT] Will digital twin revolutionize the aerospace and defense sector? [REPORT]](https://industryinsider.eu/wp-content/uploads/xdigital-twin-in-aerospace-320x167.jpg.pagespeed.ic.K-YNPhggcS.jpg)