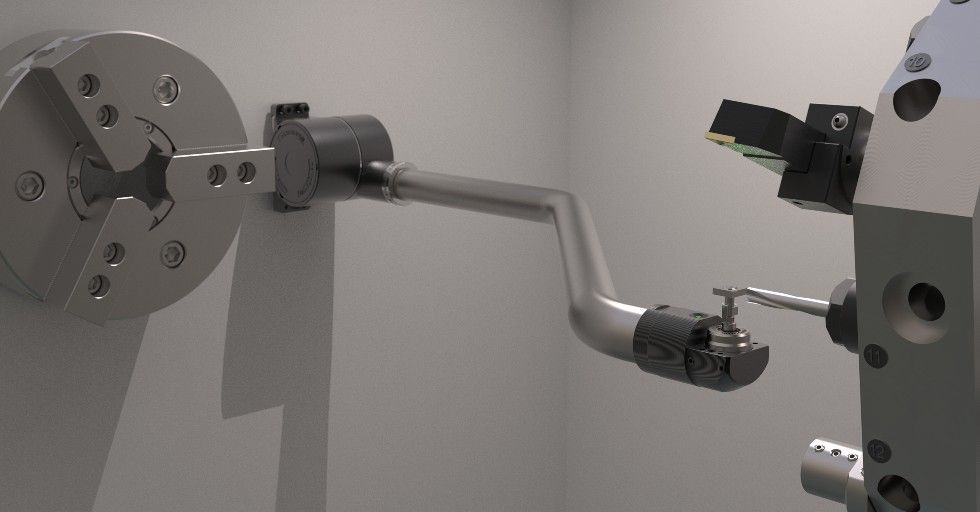

The HPMA-X is the latest addition to the company’s family of high-precision tool setting arms and has been engineered to perform in the most challenging turning applications.

Building on the success of the original high-precision motorised arm (HPMA), the latest evolution now brings high-accuracy tool setting and broken tool detection to large CNC lathes. Lathes of this size typically require longer, heavier and more complex arm designs, which can be challenging to move smoothly and repeatably.

Such designs are now possible with the HPMA-X due to an efficient and high-performance drivetrain, which includes a digitally controlled brushless motor and high-ratio 3-stage planetary gearhead. This intelligent system allows for precise speed control and collision detection, whilst maintaining high torque and powerful lift capacity.

For arms of this size, ensuring a smooth transition as the probe is moved in and out of the working environment is critical in order to maximise the life of the product. Digital control and feedback systems within the accompanying interface (TSI3-X) provide smooth motion control, resulting in consistent acceleration and deceleration characteristics.

Additionally, the TSI3-X interface incorporates four customer-facing LEDs for real-time status monitoring. These indicate the status of the input drive commands and arm confirmation outputs, as well as conveying any motion or system health issues.

Steve Petersen, Marketing Manager for Renishaw’s Machine Tool Products Division said, “We are seeing more and more manufacturers looking to implement process automation in their factories. Having machines sat idle, awaiting manual tool setting tasks is no longer an option if you want to remain competitive. The HPMA-X provides automated tool setting and broken tool detection on CNC lathes and can enable lights-out manufacturing.”

Renishaw’s precision measurement and process control technologies, like the HPMA-X, enable productive and sustainable manufacturing. They can predict, identify, and correct process errors before they happen. This helps eliminate scrap and, in turn, reduces the wasted energy, time and materials involved in producing those scrap components.

Factory automation drives operational efficiency by increasing machine uptime and overall output, without adding extra machines. Renishaw probing solutions for the automation of CNC machining processes allow manufacturers to increase machine utilisation and operate 24/7.

With process automation technologies in place, physical automation can be implemented, which increases productivity and, in turn, can reduce waste and energy consumption.

Photo: Renishaw

![Forecasts, Opportunities, and Challenges for the Polish Industry in 2024 [ANALYSIS] Forecasts, Opportunities, and Challenges for the Polish Industry in 2024 [ANALYSIS]](https://industryinsider.eu/wp-content/uploads/xIndustry-40-320x167.jpg.pagespeed.ic.o8zijDQlIJ.jpg)

![The importance of artificial intelligence in transport and automotive industry is growing [REPORT] The importance of artificial intelligence in transport and automotive industry is growing [REPORT]](https://industryinsider.eu/wp-content/uploads/xcity-320x167.jpeg.pagespeed.ic.xFkQdk7qXO.jpg)

![By 2030, the market size of metal processing tools is expected to reach $120.44 billion [REPORT] By 2030, the market size of metal processing tools is expected to reach $120.44 billion [REPORT]](https://industryinsider.eu/wp-content/uploads/xcutting-tools-320x167.jpg.pagespeed.ic.SgnEk-RWA-.jpg)

![Methane emissions remains elusive challenge for oil and gas industry [REPORT] Methane emissions remains elusive challenge for oil and gas industry [REPORT]](https://industryinsider.eu/wp-content/uploads/xMethane-emissions-by-source-320x167.jpg.pagespeed.ic.q-7jG2luXb.jpg)

![Will digital twin revolutionize the aerospace and defense sector? [REPORT] Will digital twin revolutionize the aerospace and defense sector? [REPORT]](https://industryinsider.eu/wp-content/uploads/xdigital-twin-in-aerospace-320x167.jpg.pagespeed.ic.K-YNPhggcS.jpg)