NSK solved the problem of overheating in the exhaust fan bearings at the ore processing plant, saving the customer €88,955 per year. This significant cost reduction was made possible by correctly selecting bearing and lubrication solutions that eliminated the need for compressed air cooling.

Exhaust fans are essential in ore processing plants to help remove high concentrations of airborne solid particles generated by processes such as crushing, sorting, grinding, screening, decanting, filtering and drying. In this particular installation, the operating temperature of the exhaust fan bearings was unacceptably high.

As a result, in an attempt to counteract this situation and extend the life of the bearings, the plant was using compressed air for cooling, at considerable cost.

Concerned about the ongoing costs associated with the cooling system, the company undertook a detailed assessment of the application and operating conditions of the bearings.

The review, which included value-added services such as bearing condition reports and temperature analysis, revealed serious problems with the seals on the bearings currently in use. The high speed of the bearings was causing the seal lip to burn, which, combined with excessive grease, was resulting in high operating temperatures.

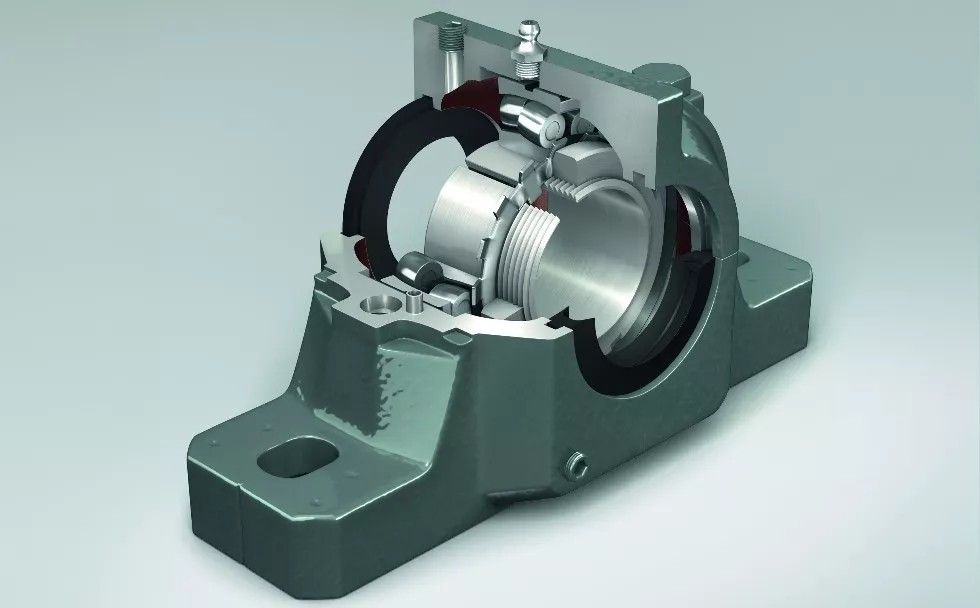

To solve the diagnosed problems, the use of NSKHPS spherical roller bearings in split SNN housings and labyrinth seals was proposed, together with recommendations for correct mounting procedures, appropriate grease quantities and optimum lubrication intervals. The upright SNN housings have two grease nipples and a drain hole to facilitate maintenance. Subsequent tests showed a significant reduction in temperature, eliminating the need to activate the compressor for air cooling.

The SNN range of modular housings offers a variety of technical options to meet the specific requirements of demanding applications such as exhaust fans. It should be noted that these components are easy to install, disassemble and maintain. Equipped with high-efficiency bearings such as the NSKHPS series, split SNN housings help companies implement cost reduction plans.

Cross-section showing the design configuration of the split SNN housing by NSK / Photo: NSK

![By 2030, the market size of metal processing tools is expected to reach $120.44 billion [REPORT] By 2030, the market size of metal processing tools is expected to reach $120.44 billion [REPORT]](https://industryinsider.eu/wp-content/uploads/xcutting-tools-320x167.jpg.pagespeed.ic.SgnEk-RWA-.jpg)