Which company is competent enough to supply machines to Renishaw?

In the world of CNC machines, there are several companies whose brand, position, significance, and offered portfolio are unquestionable. When we want to measure something during the execution of an NC program, we usually use Renishaw probing systems for this purpose. When commissioning a new machine, we typically use equipment provided by Renishaw to measure its geometry. But what happens when Renishaw wants to order a machine for its own needs? From Siemens’ offerings, it chooses the most innovative numerical control, the digital native CNC – SINUMERIK ONE, and the Polish manufacturer of 5-axis machines, FANUM.

For many years, Wielopole Skrzyńskie was mainly associated with the title of a play and its director Tadeusz Kantor, a globally renowned creator of Cricot 2 Theatre. Now, Wielopole is gaining recognition thanks to the FANUM company, which established itself in the Polish market in 2007.

When a group of engineers began constructing complex machines and equipment for the production of wooden elements in the early 1990s, CNC machine production wasn’t even in the plans. It emerged a little later, but right from the beginning in the form of sophisticated 5-axis machines with proprietary CNC software – the first of their kind produced in Poland.

The world is becoming increasingly digital. We want things faster, better, and cheaper. SIEMENS responds to these expectations by introducing the market’s first fully digital control system, SINUMERIK ONE – a digital native CNC. This control system boasts several unique features, setting trends for the next several decades. SINUMERIK ONE proudly replaces the SINUMERIK 840D SL family, whose departure from the stage was long overdue.

In the same way that multimedia replaces cinemas and theaters, avatars replace actors, and the internet and audiobooks supplant printed books and magazines, a similar innovation is occurring in the world of machines. This innovation involves the ability to launch an entire CNC machine in a virtual environment using a digital twin of the machining center before it is physically built.

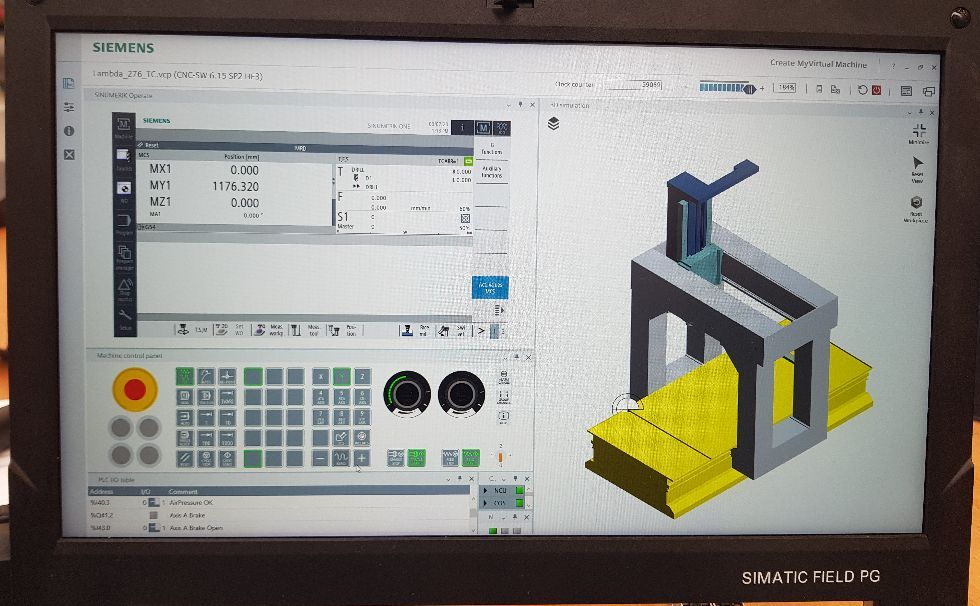

Testing NC programs, PLC, checking design assumptions, optimizing systems, and observing the movements of the 3D machine model all happen on a computer screen. This revolution is taking place before our eyes, thanks to the Create MyVirtual Machine and Run MyVirtual Machine platforms.

The company RENISHAW is a demanding client that has been collaborating with SIEMENS for many years on various fronts. They have a good understanding of what is worth considering on the market and which control system provides the highest parameters while guaranteeing the implementation of the latest technological capabilities. When the company decided to purchase a new dedicated 5-axis machine, it was evident that it had to be equipped with SINUMERIK ONE.

FANUM’s machines are built with unique features, often tailored to specific production tasks and clearly defined customer needs. However, the company had never offered a machine with the SINUMERIK system in its lineup. Launched in May 2023, the LAMBDA GT for RENISHAW was the first one, and as it quickly turned out, not the last.

The configuration of this machine goes far beyond standard solutions. Lambda GT, a Fanum project, was created as a machine dedicated to 5-axis machining of complex models and forms.

The open design of the machine, based on a fixed work table, quickly gained popularity in the market and has been one of the best-selling models of the Polish machine manufacturer for many years. The very massive support moves on four pillars driven by motors that work in tandem pairs (double gantry system).

This solution allows for active elimination of backlash while maintaining excellent axis dynamics. The double gantry system encloses the swiveling and tilting head somewhat in a cage, ensuring high rigidity of the system during demanding machining. The machine performs well with soft materials such as foams or resins, as well as in the processing of composites and aluminum.

The machine is equipped with rich software options, including SINUMERIK ONE Dynamics 5-axis Milling, an expanded version of measurement functions, OPC UA, Advanced Position Control, Friction Compensation, and Run MyHMI.

A particularly interesting example of digital solutions that have very practical applications in the machine’s operation is volumetric compensation. SIEMENS implemented the VCS-A5-plus option in SINUMERIK ONE, allowing for describing the entire coordinate system of the machine with minor corrections to achieve almost perfect geometry of the machining area during processing. The construction data obtained from measurements were input into the control system, immediately reflecting in the accuracy of the machine’s positioning. Volumetric compensation can be applied not only in new machines but also in those already in use, provided they are equipped with the SINUMERIK control system.

SINUMERIK ONE, with the applied options, ensures an exceptionally open system for machine users, supporting not only machining processes but also creating dedicated screen masks and obtaining additional functionalities and assistance for operators or technologists/programmers.

The scalability of SINUMERIK ONE and the ability to configure it by choosing from a rich offering of hardware and software components were the main goals of Fanum, enabling the transition to a higher level of machining quality and capabilities.

How to build a machine in a short time, program it, start it up, conduct all required tests, and still have time to take a few documenting photos at the end? The answer is to transfer the prototype of this machine into virtual reality. LAMBDA GT was created in this way.

The machine bodies provided by FANUM from the CAD program were placed in a virtual environment by our specialist and brought to life using Create MyVirtual Machine tools (Operate and 3D modules) in conjunction with SINUMERIK ONE. This allowed the creation of a PLC program in the TIA Portal environment for the S7-1500F controller, testing it, and virtually commissioning it without the need for access to a real machine. Testing even included advanced safety functions used in the machine.

The same virtual machine was also used for training the team of specialists working on control systems. As you can see, waiting for equipment delivery is currently not an obstacle to conducting engineering work and implementing a prototype.

The SIEMENS platforms Create MyVirtual Machine and Run MyVirtual Machine, through Open API, allow integration with any CAD/CAM software. Moreover, they reverse the conventional design process, tremendously shortening the time it takes to bring a machining tool to market. For simulation, instead of using emulation of control operation, they utilize the virtual core (kernel) of the SINUMERIK NC, identical to that in a real machine.

Therefore, a digital twin created on the Create MyVirtual Machine and Run MyVirtual Machine platforms is a representation of the real numerical control system of the machine, including the operation of PLC, processing of drive data, NCK data, background system processes, peripherals, functional human-machine interface (HMI) panel, and a personalized machine keyboard. And most importantly, such a digital twin emerges before the actual machine is built, not only afterwards!

This fact is the main advantage of the entire operation. It allows for the simultaneous development of multiple issues and the creation of several variants of one solution at the same time. Preparing the machine in a virtual environment enables the detection of various errors and potential imperfections at a stage where operations are almost cost-free. It’s a bit like assessing the performance of actors before they appear on stage. The show hasn’t started yet, but you already know whether it will be successful.

Machines are often sent to distant countries, and the LAMBDA GT with SINUMERIK ONE also went overseas. Sending the first machine produced with a new control system abroad is perceived as very risky. Because it’s far, because of service costs… Or is it really?

After all, the digital twin of the machine remains in place. Virtually everything can be tested on it. In the age of ubiquitous computer networks, remote access to the machine is not a challenge. The engineering tools and technical capabilities of SINUMERIK ONE allow for servicing, parameterization, modification of PLC, or machine data from the company’s headquarters. Of course, the eventual replacement of damaged hardware must be done by someone at the machine, but all diagnostics can be performed without the need for physical presence.

The digital twin created or reproduced on the platforms Create MyVirtual Machine and Run MyVirtual Machine allows for even more. These platforms, equipped with the SIMIT module and NX Mechatronic Concept Designer (MCD), provide the ability to simulate not only discrete signals but also continuous processes. This includes analog inputs/outputs interacting with sensors on the machine, imparting the full physics of the rigid body to the machine, along with the inertia forces acting on the kinematic system. Therefore, the operation of the machine will change depending on fully configurable parameters of physical quantities such as temperature, hydraulics, pneumatics, lubrication, and any other continuous process created by the manufacturer.

The digital twin is not just a result of human fascination with virtual reality. Its use brings tangible benefits: you can see how a particular machine will look, how it will operate, and what its functions will be. And all of this without using even a single gram of metal to build the structure.

The virtual SINUMERIK ONE animates the virtual machine. We can test the PLC program without purchasing the central unit or even a single input/output module. We can create a real machining program in the virtual environment and check how long it will take to execute it (differences between the virtual and real machine times are below a fraction of a percent!).

But that’s not all. At the next level of abstraction, there is the virtual commissioning of the machine, allowing us to upload a complete set of machine data to the prototype from a USB memory, and if all formalities have been completed, the machine should practically start working correctly right away.

The action of Tadeusz Kantor’s art “Wielopole, Wielopole” takes place in the Room of Imagination. SINUMERIK ONE and the environment in which it was created and operates allow us to extend the boundaries of the virtual room very far. It’s just a matter of imagination… and modern tools provided by SIEMENS.

All elements of the performance must harmonize perfectly and complement each other. Operators and machine users are offered colors, applications, dedicated solutions. SINUMERIK ONE fits into these trends. Graphic screens, expandable side auxiliary screens, three-dimensional simulation, gesture-based screen operation (as on a typical smartphone), network operation, document display, connection of cameras for previewing the workspace on the control system screen, operation of any CAM software from the machine… SINUMERIK ONE is truly versatile.

For enthusiasts, we also offer solutions utilizing Edge Computing (known as Industrial Edge for Machine Tools). They are used to collect data about what is happening on the machine for analysis. For example, using vision systems, neural networks can be trained on correctly and incorrectly mounted parts by operators or robots, monitoring all production data, including rapidly changing data with short sampling times (determined by the interpolator cycle), data on inverter drives, servo motors, energy consumption, or process optimization… And that’s still not all.

There is also the Optimize MyMachining/AdaptiveControl system (adaptive control of axis speeds during machining), which, by monitoring spindle parameters, “boosts feed” to shorten machining time, simultaneously monitoring potential tool damage (goodbye to material shortages, etc.).

For fans of small and useful gadgets, we have the SINUMERIK Powerride handwheel. It is a cross between a typical potentiometer with a start button, a set of colored lights, and haptic feedback within specified adjustment ranges.

Operators no longer have to take their hands off the MCP (Machine Control Panel). They can focus on observing the machining area, which is particularly important when implementing a new program on the machine. START, STOP, executing the next block, faster/slower, haptic control function (vibrations) of the potentiometers when changing from 0% to 100% and above, allowing you to feel that the value set is too high. Simpler, safer, and with the Configured STOP function integrated into the new Powerride, we have the ability to describe any optional STOP with its configuration, e.g., from G0 to G1, from G1 to G0.

Every art form requires a stage, actors, and an audience. In this triangle, all the magic happens. The success of whether the art is liked or will quickly go off the billboards is measured by new viewers, encouraged by the previous ones.

The proposed solutions aim to streamline the processes of machine creation and testing, speeding up their production. The digital twin is just one of the actors in this art. It allows for conducting design and programming work at a time when the machines physically do not exist yet. With its help, you can also show the future customer how their ordered machine will look or function, taking into account details such as screen masks and displayed messages. You no longer have to imagine this, although imagination supported by engineering knowledge allows creating this virtual model.

SIEMENS is committed to building long-term and stable relationships with machine manufacturers. From the first visit and presentation of the equipment, through the entire start-up process, to the final test before sending the machine to the customer. The production of the LAMBDA GT machine by FANUM is an exemplary example of this methodology.

FANUM has decidedly opted for the use of SINUMERIK systems, starting with the ONE model. The latest control model and designed for such a demanding customer as RENISHAW. After the equipment presentation stage, during technical discussions, a set of components for this specific machine was refined. From that moment on, work was carried out on three parallel fronts: order fulfillment, design and creation of mechanical structures, and training and programming using the digital twin.

Providing dedicated technical and training support, carried out exclusively by local SIEMENS specialists, full access to documentation and software, on-site start-up support, as well as assistance in creating PLC projects and optimizing drives, allowed a company that had never used SINUMERIK systems in its machines before to prepare the machine “from scratch” in record time.

Is there an encore in this art? We are pleased to announce that it is already underway: Fanum is currently fulfilling an order for more Lambda GT machines for the same customer, with an even more complex specification, and of course, also with SINUMERIK ONE control.

If you are interested, we will be happy to help you stage your art as well. And that will be a cash success too. SINUMERIK ONE is a star of the first magnitude, worth hiring.

Digital Industries MC MTS / SIEMENS Sp. z o. o.

email: automatyka.pl@siemens.com

![By 2030, the market size of metal processing tools is expected to reach $120.44 billion [REPORT] By 2030, the market size of metal processing tools is expected to reach $120.44 billion [REPORT]](https://industryinsider.eu/wp-content/uploads/xcutting-tools-320x167.jpg.pagespeed.ic.SgnEk-RWA-.jpg)