Through the relocation of specialized units from Mönchengladbach to Rorschacherberg, the Rorschacherberg facility has become a 100% dedicated center for aviation and aerospace, known as the ATCC (Aerospace and Turbine Competence Center).

In this way, the Starrag Group has placed another important cornerstone for the future of the Rorschacherberg facility. Rainer Hungerbühler, Director of Sales for Aerospace & Turbines, describes the new structure and specialization scope that has developed within Starrag in Switzerland in an exclusive interview for SMM.

Starrag AG focuses its activities in the aviation and aerospace industry at the Rorschacherberg facility. What does this mean?

Rainer Hungerbühler: Essentially, the scope of our competencies at the Aerospace Competence Center in Rorschacherberg is straightforward to define. Through our manufacturing technologies, we focus on six groups of components that are strategically significant in the aviation and aerospace industry. Specifically, these are rotors, rotors with integrated blades (blisks), turbine blades, housings for drive mechanisms, as well as structural parts made of titanium and aluminum.

It is for these components that we develop and continually optimize our technological and manufacturing solutions. Our specialization is thus clear. On the other hand, the production strategies required for this are complex and technology-dependent. Our focus on aviation and aerospace, combined with our high technological standards and production experience, is, in my opinion, a unique asset for the Rorschacherberg facility.

Could you specify this further?

The Aerospace Competence Center is the result of the consistent development of our existing range of competencies. Our focus on the aviation and aerospace industry has continually evolved over the past decades. We have an excellent position in 5-axis simultaneous machining of difficult-to-cut components, as well as in machining structural parts (aluminum and titanium).

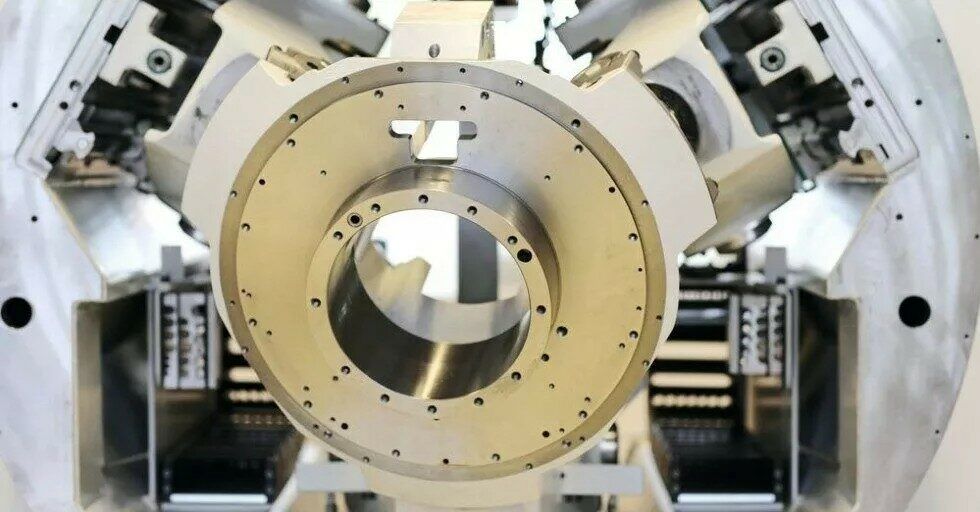

Our technology implementation center – ATCC (Aerospace and Turbines Competence Center) – with an area of approximately 2000 m2, is equipped with the latest 5-axis machining centers of the NB, LX, and STC types, which can produce various flow surfaces and complex structural components.

Specific assembly areas from the Mönchengladbach facility were relocated to other facilities, and here in Rorschacherberg, “Ecospeed” products are now assembled. Could you tell us more about this?

The assembly of Ecospeed was moved to Rorschacherberg to centralize our production solutions in the aviation and aerospace field. I would like to emphasize that only the assembly of specific product types was relocated to Mönchengladbach. In Mönchengladbach, we still handle design, development, service, as well as retrofitting with a workforce of 120 employees. We already had production solutions for structural parts in place here. With Ecospeed, we can showcase solutions for very large structural components to our aviation and aerospace customers on-site. Ecospeed is an excellent addition to our range of competencies in aviation and aerospace technologies at ATCC.

Does this have implications for the types of turbines you produce components for, with a keyword being steam turbines?

Materials used in steam turbines are easier to machine because these materials are typically used at lower temperatures. Our machines are designed for high-efficiency machining of components from difficult-to-cut materials. When it comes to machining steam turbine components, we focus on the high efficiency of our solutions.

However, gas turbines also use components made of Inconel alloy. That’s correct, but in the energy sector, there is currently less investment, which also has an impact on the demand for production solutions. Therefore, most of our machining capacity is currently dedicated to aviation and aerospace projects. In the energy sector, we are correspondingly less active at ATCC. Nevertheless, gas turbine manufacturers also integrate blades in gas turbines because it enhances their efficiency. Integrated blades offer optimization potential and enable designs with lower inertial masses, allowing for more cost-effective gas turbine starts and stops.

Could you explain specifically what technology sectors you have expertise in?

Our primary know-how lies in the development and construction of high-performance machining centers for the aforementioned industries. That’s our foundation. Additionally, we have expertise in the entire process, from tools and CAM software for single and multi-blade tools to automation, clamping techniques, and fixture construction, including measurement strategies. When a customer approaches us to produce a new component, we can develop a complete production strategy together, from tool edge design to manipulator. Our CAM software is also geared toward developing optimal milling strategies for flow components.

With your relatively large machine park at ATCC, how is it used?

Generally, at ATCC, we develop production strategies for our customers. Due to our significant production capacity, in specific cases, we can also take over part of the production from our customers in a short time. What does this mean: when a customer orders a new machining center, we can develop the production process at our facility and start producing components.

After delivering the new machine, we provide our customer with all the components and CAM data, so their new machining center can start producing quality parts as quickly as possible. This is a significant advantage, especially for very complex structural components.

Why is it so important for a machine tool manufacturer to focus on a specific area like aviation and aerospace, and what are the challenges in this field?

The reason we have such a strong position in aviation and aerospace today is due to our competence in this area. In aerospace technology, the most complex components are manufactured, and they cannot be produced without specially designed machine tools. For this reason, we developed, for example, our extremely slim, forked milling head, which was designed to meet specific production requirements. As I mentioned earlier, we specialize in producing the six components mentioned above for aviation and aerospace. Our goal is to provide the most productive solution at the lowest unit costs. That is our strategy.

In this field, we must maintain and continuously increase our competitive edge. Our machines must be highly efficient so that our customers can manufacture competitively. This means reducing lead times and auxiliary times. Tool wear is a significant cost driver, especially when dealing with difficult-to-machine materials. We evolve along with the challenges our customers present to us.

What does this mean for you as a machine tool manufacturer?

If we design a machine and process to allow for the use of tools with a small reach, it is a significant factor in increasing tool life. At the same time, the volume of material removed per unit of time increases. Often, we may not be aware of it, but the larger the reach of the tool, the more unstable the machining process becomes. For normal steel machining, this may not be critical today, but when cutting materials like inconel, hastelloy, or titanium, it makes a huge difference.

Especially in the production of components for aviation and aerospace, geometries are manufactured that cannot be achieved without special tools. Moreover, some of them are made from the most demanding materials, such as Inconel. What competencies do you have in the development and production of tools, including their coating?

Tooling is one of many critical components to design the entire process in a stable and cost-effective manner. The design of the tool plays a significant role. If we look at well-established trochoidal milling processes today, it’s a brilliant synergy from CAM software through machine control and dynamics to milling tools specially developed for this process.

Such a process chain plays a decisive role when it comes to structural parts for which our machining solutions are designed. Automation and 24/7 operation also come into play. This means that tools must be perfectly designed not only for the production process itself but also to ensure high process reliability.

Speaking of tools, what role do special tools play in this segment?

Special tools are used when they provide benefits in production strategy as well as in overall cost calculations. It’s all about maintaining a low cost of component production. We have a tool development department dedicated to aerospace production, which, together with CAM specialists, develops and sharpens tools with a process-oriented approach. The data for these milling tools are digitally stored, and replacement tools can be produced and delivered at any time.

Regarding your machine tools, to what extent are they standard, and to what extent are they the result of project work?

Due to the complexity of the components, we often conduct specific project work. The foundation of all production solutions is our standard machining centers, which are optimally adapted through specific configurations for the given application.

Regarding Inconel: Often, materials with high strength need to be machined. How does this translate into the machine’s concept, the entire process, and ensuring an efficient production process?

From a machine design perspective, it’s crucial to have the spindle nose with the smallest possible excluded space as close as possible to the machining area of the structural part. Why is this important? Such a machine design allows us to use tools with a small reach. For example, conventional standard forked milling heads have too much volume, which would require longer tools, making the process more unstable. Our entire machine concept is designed so that machining is conducted in conditions of high stiffness.

This applies, for example, to our extremely compact forked milling head, which was developed with specific production requirements in mind. From a design standpoint, this is an extraordinary challenge for our engineering designers. Good production results are the reward for outstanding achievements in the development work of our department.

In the production of structural components, high machining efficiency is partly required. What does this mean for the production process itself, and what characterizes a perfect machining process for structural components from your perspective?

It’s great that you’re addressing this topic. So far, the focus has been on components made of difficult-to-machine materials. With the introduction of the Ecospeed product line among Starrag Group products, additional production solutions for structural parts made of aluminum have been added. Aluminum and titanium structural parts require different machining concepts, even if the shapes of these parts are similar. For titanium machining, machines require very high torque, high damping, short tool reaches, and high feed forces.

Damping—through damping systems integrated into the machine—can be specifically adjusted through control. In the case of titanium, high accelerations are not needed; the crucial factors are feed force and torque. The STC-X series has been specially designed for aluminum part machining. Machines in this series have tremendous dynamics, optimized chip flow, and suitable cooling. The Ecospeed machine is 100% designed for large aluminum structural components.

Regarding the Ecospeed machine that you now produce in Rorschacherberg, could you provide more details about it?

Ecospeed machines are designed for high-volume machining of very large components. Thanks to the machine’s dynamics, special kinematics, and high performance, our customers achieve unit times that are unattainable for other machines on the market. The Ecospeed machine allows for machining the largest aluminum structural parts of aircraft with unparalleled efficiency. The Ecospeed machine features a unique, parallel kinematic milling head, which is a worldwide innovation in terms of design.

A final question: Switzerland, except for Pilatus and partly Ruag, is not typically seen as an aerospace or space industry hub. How did this sector develop so well within Starrag in Switzerland?

We are 95% export-oriented. Our customers are not right on our doorstep. We have a relatively narrow specialization. As for our roots, we originated from the turbine construction sector, which had an excellent position in Switzerland and still does. Transitioning to aircraft propulsion is a significant technological shift, but not an entirely different one. Generally speaking, Swiss companies tend to focus on technologically niche markets. Aviation and aerospace are precisely such sectors where we have gained a reputation and aim to position ourselves even more strongly in the future.