Three examples of how indoor location technology has increased productivity in industry: Volkswagen, Budweiser and Enel

Time is not only of immense importance to industry, it also determines the fine line between maximising profitability, wasting money on inefficient processes and “bottlenecks”, and risking the safety of employees. Leading companies such as Volkswagen, Budweiser and Enel have overcome this problem by implementing a real-time tracking system in their facilities. This has enabled them to increase the transparency of production and logistics processes, eliminate costly bottlenecks and significantly improve operational efficiency and employee safety.

Business in higher gear

Volkswagen Slovakia manufactures five car brands at its plant. This means that determining the exact location and status of the forklift fleet and its routes is crucial for full fleet utilisation and high efficiency of their journeys.

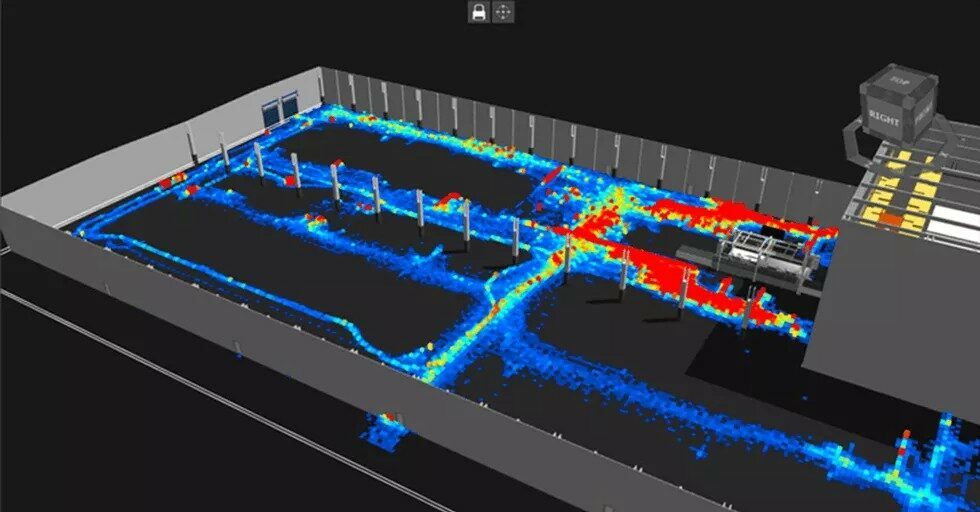

Thanks to the implementation of Sewio’s Ultra-Wideband Real-Time Location System (UWB RTLS), Volkswagen Slovakia has gained insight into the current status of the fleet and the history of routes – including spaghetti diagrams, heat maps, and indicators and performance parameters of the forklift fleet and Automated Guided Vehicles (AGVs). It is also able to help drivers choose the optimum route and avoid ‘bottlenecks’, which has contributed to a 10% reduction in the total distance travelled by the fleet.

Knowing the location of forklifts that are not moving or involved in loading or unloading at any given time has also made it possible to identify unused warehouse space. Thanks to the optimisation introduced as a result of this analysis, the storage area “increased” by 20% without any structural changes – simply by improving its use.

Beer is fundamental

The name Budweiser is inextricably linked with beer. The company’s brewery holds 20,000 pallets of beer in two sizes and 360 varieties. They are shipped to 76 countries around the world, and the plant sends out 50 trucks loaded with beer every day. In order to fulfil orders on a global scale, Budweiser needed a new real-time positioning system that would minimise the scope and impact of human error when working with such large quantities of varied products – while requiring no significant maintenance.

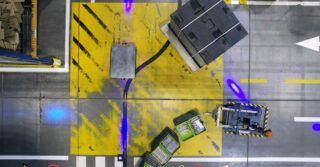

By equipping 15 forklifts operating in a 15,000m² warehouse with UWB tags and using 70 receivers (anchors), Budweiser can now track the location of 20,000 pallets in real time with an accuracy of up to 30cm. This allows the company to verify that each driver has picked up the correct pallet and unloaded it at the correct location, and to send appropriate instructions if an error is made.

Replacing the radio frequency identification (RFID) system with the UWB RTLS system resulted in a 24% increase in system uptime (to 99%) and a 19% improvement in warehouse utilisation. Logistics managers now have a complete set of indicators on staff presence, distance travelled and utilisation of each forklift

Safety at work comes first

Industrial safety is a key issue for modern companies, and this is no different for Enel, a ‘green energy’ producer operating in 30 countries. At the San Giacomo hydroelectric power station, it’s essential to keep track of the number of people and vehicles on site.

With two kilometres of tunnels and other internal areas, the ability to respond quickly and accurately in an emergency can be life-saving. It also helps to eliminate further hazards and prevent unauthorised personnel from entering restricted areas.

Due to the size of the site, the often high humidity and the relatively high average speed of vehicles (30 km/h), individual areas and transit zones had to be divided into ‘micro-areas’. Using UWB RTLS tags in conjunction with RGB cameras, Enel can now identify employees, vehicles and their real-time location.

The cameras make it possible to determine the number of people present in a given area, even if they are not wearing tags. As a result of the changes implemented, the number of cases of unauthorised entry into restricted areas fell by 81% and the generation of attendance reports became easier and less error-prone. What’s more, in the event of an emergency, people can be reached more quickly.

Time is on your side

Digitalisation provides real insight into the operation of facilities and the activities of people, equipment and vehicles within them. With highly accurate positioning, process improvement and increased safety for those directly responsible, the benefits of using these technologies are undeniable – and the financial savings significant. Time no longer has to be your enemy; it can be your ally.