In recent decades, lithium-ion batteries (lithium batteries) have become part of our daily lives, whether it be in mobile phones, kitchen appliances or electric vehicles. Lithium batteries are appealing to both producers of goods and the consumers who use them: with high energy and power density, rechargeability, and portability, they can be an ideal power solution in our fast-moving world¹. Plus, as the world transitions to more sustainable energy use, we can expect exponential growth of this key input in electric vehicles and other sustainable products. In fact, industry experts predict over 30 percent annual growth of the entire lithium battery supply chain, from mining through to recycling, from 2022 to 2030².

With that growth naturally comes an increase in demand for transporting these batteries, both from consumers who are buying, selling, and returning commodities containing batteries, as well as from businesses. In the automotive industry, for example, the average share of electric cars in total sales across China, the EU and the US is set to rise to around 60% by 2030³. This in turn, will lead to a growing demand for the transportation of lithium batteries.

Though seemingly ubiquitous in products we use every day, lithium batteries aren’t without risks. Often triggered by an overcharged or damaged battery that short circuits, they are known to spontaneously combust, or they may heat to the point where they cause a thermal event. An exploding lithium battery creates a fire of approximately 2,000 degrees Celsius. More importantly, because the lithium salts in the battery are self-oxidizing, it can’t be extinguished like a traditional fire.

Taking in-air safety seriously

Because of the risks posed by lithium batteries, the aviation industry takes very seriously the development of safety protocols and best practices for transporting them. Lithium batteries are classified by the International Air Transport Association (IATA) as dangerous goods (DG) class nine. As one of the world’s largest DG carriers worldwide, and member of the IATA Dangerous Goods Board, FedEx actively contributes to standards and procedures on the safe transportation of DG by air. The Board meets periodically to discuss advances or problems that are commonly seen and come up with solutions. Though the IATA Dangerous Goods regulations are not themselves law, many countries incorporate the provisions into domestic law.

Whenever lithium battery shipments travel by air, a number of safety measures are taken when loading the aircraft. This includes a practice known as ‘segregating the load,’ where lithium batteries are stored separately from highly flammable goods. In addition, shipments containing lithium batteries are not carried on open pallets. Closed containers are used to limit the spread of potential fire or combustion when exposed to heat. Lithium battery shipments will also not be loaded together with heavy freight that could potentially cause damage if it were to move in flight.

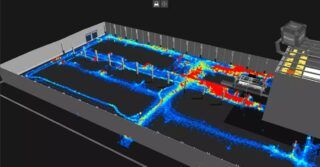

Safety is further enhanced by using fire suppression covers, and in our Boeing 777 and MD-11 aircraft crossing the Atlantic and the Pacific, we use a built-in fire suppression system. The system, developed by FedEx, is installed on the main cargo deck and monitors significant increases in container temperatures. The system status panel provides the flight crew with the operational status, and, in case of a suspected fire, will identify the container position in order to deploy a fire-extinguishing agent.

Safe handling begins before the cargo hold

To ensure the safe air transport of lithium batteries, every stakeholder involved must ensure proper handling and care at each step of the transport process:

Producers

Firstly, the manufacturer of the batteries is responsible for ensuring that batteries are packaged so the state of charge is not above the regulatory maximum. Knowing that battery innovation is leading to batteries with increased power capacity, we work closely with our customers to create new solutions for safe transport. One area of focus is the automotive industry. As a licensed carrier to transport test-batteries, we support battery research and development. By providing emergency batteries, we support stalling production lines, and for the aftermarket, we are delivering spare parts.

Whereas most carriers accept DG shipments up to 35 kilograms, FedEx is one of the few that ships DG above that weight. This enables the transportation of electric car batteries, both within Europe and intercontinentally. One of the advantages of being a global integrator is that we can use both our air and our road networks to transport shipments containing lithium batteries. Especially for our automotive customers, our extensive network enables global connectivity as well as cost effective options via road in Europe.

Shippers

Secondly, the shipper must properly package, mark, and label all DG shipments.

Visibility into the safe carriage of lithium batteries starts with the customer making sure the shipment is recognised as a lithium battery shipment by adding the appropriate label and correct UN identification number on the outside packaging. Shipments without the correct mark and label, or with the label only partially visible, cannot be accepted for transport. The same goes for damaged packaging.

Next, a DG handling code is added to the shipment data, identifying it as a dangerous goods shipment. Throughout the entire journey, from the origin through each transit location, and finally at the end station through to delivery, the package will be checked for exterior or visible damages, which can indicate that the contents may also be damaged or leaking.

Most commercial shippers, especially those in the automotive industry, are experts on the requirements for shipping lithium batteries. For the occasional shippers of lithium batteries, and for intermediaries like online selling platforms or consumers, FedEx provides online guidance on shipping lithium batteries. These resources are designed to create awareness of a shipper’s responsibility, including understanding the necessary regulations in place and applicable to them, how to handle faulty equipment, and how to package and mark the shipment correctly.

During Transport

Training is one of the main priorities, not just for our FedEx DG experts across Europe and the people handling the shipments, but also for frontline sales and customer experience teams. Knowing what to ask and being able to help customers identify DG and mitigate risks before a lithium battery shipment enters our network, is crucial. As is knowing how to recognise and handle a shipment that shows red flags during the shipping process.

Couriers and warehouse handlers are trained annually to recognise DG shipments and handle any red flags like missing DG labels or potential safety risks. The same goes for DG specialists and advisors, making sure their knowledge of regulation and paperwork requirements are updated continuously to be able to support their FedEx colleagues and customers.

The best mitigation is prevention

As much as a flight crew trains to mitigate a lithium battery-related emergency in-flight, the best way to handle an incident is to prevent it in the first place—before a battery ever enters a cargo hold. With lithium battery shipment volumes growing worldwide, collaboration, education, and proper handling remain vital to ensure the safe transportation of batteries in the skies.

FedEx continues to advocate for stepped up enforcement efforts against those individuals and companies who willfully or recklessly violate regulatory requirements for lithium batteries. In the same vein, we support additional outreach by governments to their counterparts to enhance knowledge and awareness regarding the regulatory requirements.

As aviation industry professionals who work every day to get our aircraft from Point A to Point B safely, we must help our industry partners and customers to be educated on proper protocols and to remain vigilant when it comes to shipping lithium batteries. Safety starts well before takeoff.