Valeo has added two mobile robots to its windscreen wiper plant in Skawina, further optimising internal transport processes and increasing flexibility. Valeo, a French automotive supplier, has a global presence with plants around the world, including four production sites in Poland.

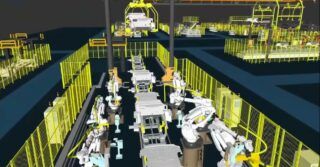

In operation since 2001, the Skawina plant is one of the largest windscreen wiper factories in the world and the largest in Valeo’s portfolio.

One of the challenges of this implementation was the variety of pallet carriers used. “Each customer uses its own type of pallet. We are a manufacturer that has to adapt to the customer, which means that each line has a different way of delivering goods. In addition, there are different sizes of roads within the plant,” explains Dominik Wąsiel, Site Supply Chain Manager & Regional Supply Chain Engineer and Development Manager at Valeo, Windshield Systems Production Plant in Skawina.

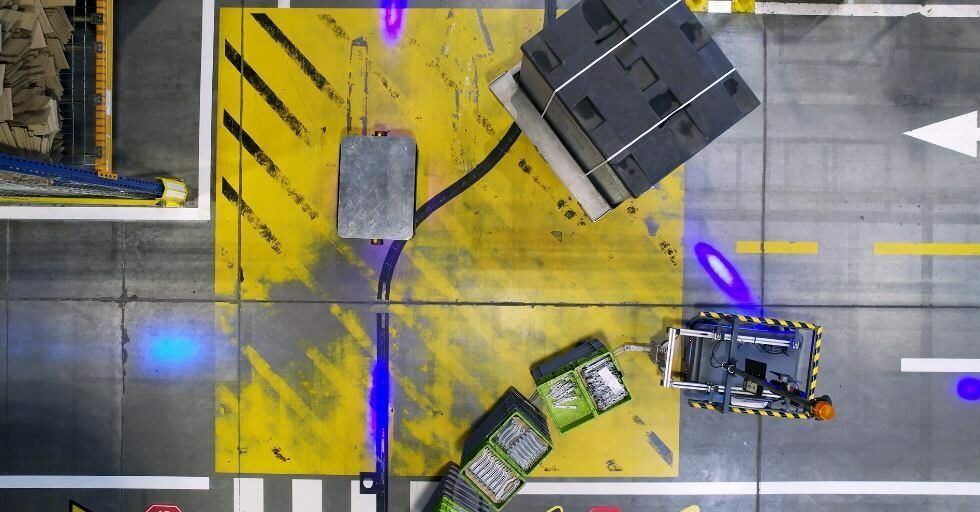

The first mobile robot was implemented in 2020 to transport components on the assembly floor. Four robots are currently in use, including two MiR250 robots. The mobile robots transport containers with components on specially prepared trolleys with racks and pull them behind them using a co-operating hook.

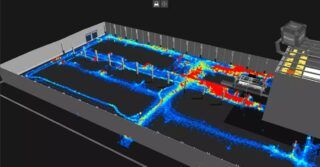

Tasks are dynamically assigned to the robots based on their current location and mission workload. Fleet management software monitors the order queue. The robots move approximately 18 pallets per hour. The fleet software allows the robot utilisation to be monitored and safety stock to be maintained for increased production or to test new solutions.

The cost of logistics, the cost of on-time delivery to customers, is a significant item in our profit and loss account. Every opportunity for automation is crucial from the point of view of the profitability of our plant,” says Michał Odyniec, Director of Valeo’s Windshield Systems Production Plant in Skawina

“The automation of intralogistics has significantly improved the efficiency of our processes. We estimate that the investment will pay for itself in about 12 months“, adds Dominik Wąsiel.

“Improving safety, eliminating damage and saving time are just a few examples of the many benefits we have gained from using mobile robots”, says Michał Kanarek, Warehouse Manager at Valeo, Windshield Systems Production Plant in Skawina.

The implementation was carried out by the Krakow-based company ASTOR.