Hand wrapping pallets becomes uneconomical as pallet handling increases. The manufacturing and distribution industries are signaling problems with delayed shipments, high material costs and resource challenges in the pallet wrapping process.

It’s easy to imagine the scale of savings that can be achieved in manufacturing plants and distribution centres that process hundreds of thousands or even tens of thousands of pallets per year.

Issues in manufacturing and distribution centres

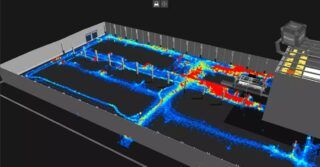

As a company that works with distribution centres, we have seen the significant impact of pallet transit time, the way in which pallets are prepared for transport and the planning of adequate internal logistics and space management. The correct placement of goods in the warehouse, the time it takes to complete a pallet, move it for stretch wrapping, and the working time of the wrapping staff or automatic wrapper are all critical factors.

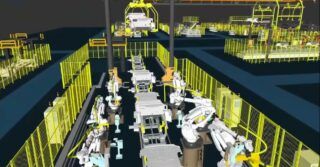

With a large number of pallets being processed, every second can be as valuable as gold. For manufacturing plants, the correct placement of machinery to effectively integrate processes and save space is also essential. However, the quality of the product and its packaging is crucial to avoid damage during transport.

Manufacturing plants and distribution centres that handle large volumes of goods must constantly seek to optimise various processes, one of which is the preparation of pallets for shipping. Neglecting to optimise pallet wrapping can result in inadequate protection for some pallets, a higher customer complaint rate, increased costs or longer pallet preparation time.

Is an automatic pallet wrapper necessary?

The time it takes to improve the efficiency of manufacturing processes is critical for the plant. Similarly, the time in which a distribution centre improves the efficiency of its picking operations. It is important to remember that if we increase the efficiency of these processes, we will also need to speed up pallet wrapping or increase the storage space for pallets waiting to be wrapped.

How can we solve the “issue” of increasing efficiency?

Increase the number of people employed or the number of hours worked:

This would work for one or two shifts, because with three shifts the number of pallets waiting to be wrapped would accumulate and sooner or later there wouldn’t be enough space in the warehouse. But even with two shifts, if we have enough space for pallets before they are wrapped, we extend the preparation time for pallets for distribution. They wait to be wrapped instead of waiting in the warehouse.

In this case, we also increase costs by increasing the number of workers or extending their working hours.

Reduce production/picking efficiency:

We can also reduce the efficiency of product manufacturing/pallet picking to allow the wrapping process to keep up, but this limits the ability to execute the production plan.

Increase wrapping efficiency by using automatic or semi-automatic wrappers:

Increasing the efficiency of pallet wrapping seems to be the optimal solution. We don’t need extra people or time to prepare pallets, so we avoid extra costs. The wrapping machine itself is an additional cost, but the return on investment in such a machine can be as little as one year. This depends on the individual case and the chosen wrapper.

These machines are characterised by repeatability, the ability to stretch the film more and savings on the film itself through optimum consumption. This solution also ensures greater product safety during transport, minimising the risk of customer complaints.

Considering pallet wrappers in other cases

Pallet wrappers are most effective where there is a high volume of pallets being processed, but turntable wrappers can also be suitable for smaller production runs. Turntable wrappers are characterised by lower efficiency at a lower cost.

In addition, as mentioned above, pallet wrappers are not only highly efficient (up to 160 pallets per hour), but they also offer a number of other benefits:

- Minimization of the risk of complaints due to improper securing

- Material savings (stretch film)

- Consistent pallet quality

- Reduction in product shipping time

- Increased pallet protection

- Wrapping unevenly stacked products on the pallet

- Streamlining processes

Summary

Optimising the pallet wrapping process is one of the most important savings opportunities for growing companies in the manufacturing and distribution industries. It is therefore worthwhile not to overlook this opportunity and to consider its cost-effectiveness for your own facility.

In Proster’s offer, you will find ➡ Tosa pallet wrappers ⬅ providing an additional benefit – a special approach to preventive maintenance, ensuring long-term operation. These solutions deliver real savings in maintenance, up to 75%, and the oldest Tosa machine in operation has been in use for over 35 years(!). We not only sell pallet wrappers, we also install and service them under warranty.

We also help to reduce production and distribution costs and advise on process optimisation when introducing automation.

![Forecasts, Opportunities, and Challenges for the Polish Industry in 2024 [ANALYSIS] Forecasts, Opportunities, and Challenges for the Polish Industry in 2024 [ANALYSIS]](https://industryinsider.eu/wp-content/uploads/xIndustry-40-320x167.jpg.pagespeed.ic.o8zijDQlIJ.jpg)