ORBCOMM announced three solutions for transparently tracking and controlling all types of freight in containers, trailers and trucks. The new and easy-to-install cold chain management solution ensures that logisticians can quickly have customisable real-time monitoring options and thus reliable control options for trucks, vans, refrigerated/dry trailers and intermodal containers – regardless of load, location, time and means of transport.

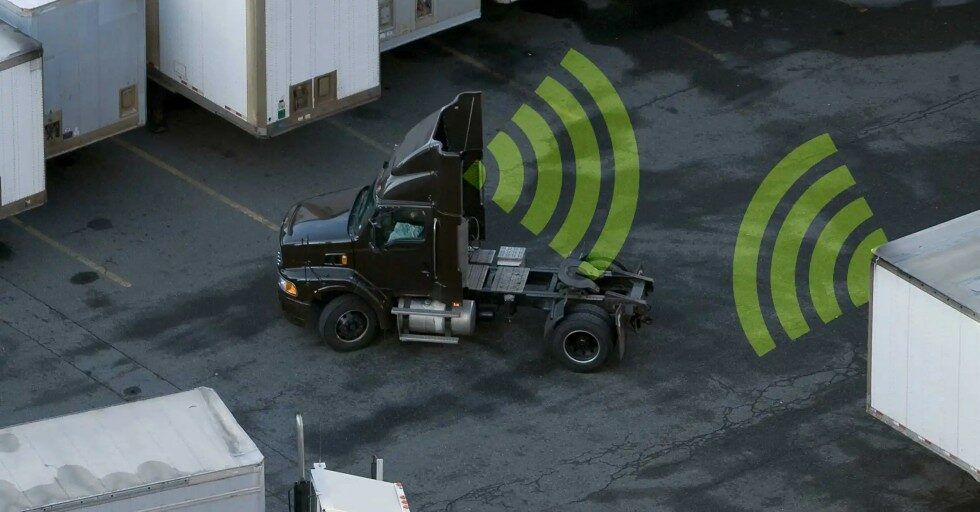

Perfectly tailored to the rough requirements of maritime transport routes is ORBCOMM’s solution for the continuous monitoring of dry containers being transported across the world’s oceans. Real-time information on the location of trailers and containers as well as the condition of the cargo is provided by ORBCOMM’s dry trailer tracking and monitoring, which ensures transparency at all times, together with optional global satellite connectivity, cargo camera sensors and tractor ID sensors.

Based on the RT 8 series of devices, ORBCOMM is showing its new cold chain management solution. The RT 8000 solution offers real-time temperature monitoring, comprehensive data acquisition and is compatible with wireless sensors for refrigerated trailers, trucks and vans. It provides temperature-controlled transport companies with a wide range of fuel and temperature management, maintenance and logistics services.

In addition, they have additional connectivity and bandwidth thanks to 5G connections, improved EN 12830 compliance, several new interfaces and the latest wireless temperature sensors. This enables them to meet a wide range of traceability, compliance and control requirements.

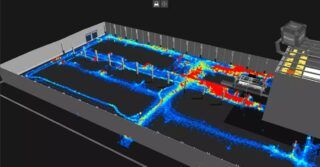

- When are the containers moving?

- How much progress has the container shipment from Shanghai made?

- How long has the cargo remained in the port?

Answers to these questions are provided by the new telematics solution for seamless monitoring of dry marine containers that pass through complex supply chains around the globe.

The new ORBCOMM CT 1000 device digitises global container shipping and provides shipping lines and their customers with constantly updated information and reliable traceability. This enables them to implement decisions on maritime activities based on valid real-time data. The solution, which is used by Hapag Lloyd among others, offers cost-effective and worldwide LTE coverage and supports a wide range of standard wireless sensors via Bluetooth.

A high degree of safety, reliability and long service life when monitoring trailers, containers and chassis is offered by the wide range of solutions for dry trailer tracking and monitoring. It includes not only solar-powered tracking devices with or without integrated load sensor (GT 1200/1210), but also additional cargo camera sensors for monitoring the load (CS 500) and tractor ID sensors for pairing trucks with trailers (IS 400). While the cargo camera sensor automatically or manually takes interior pictures of trailers to optimise loading as well as pictures of the load at various driving events, the tractor ID solution ensures that the correct trailers are connected to the truck. The rugged ST 2100 satellite tracking device provides reliable and cost-effective satellite connectivity for a wide range of industrial equipment in remote locations. Environmentally sealed, it can be installed on both fixed and mobile equipment for a wide range of applications.