Bosch Rexroth has created a modern Industry 4.0 showroom as part of its innovative CU.BE (Customer Benefit) centre network. The benefits of automation solutions and the presentation of the latest products in action were the motivation behind the creation of a place that can be visited in person at the company’s headquarters in Warsaw. The showroom is also available in virtual form for interested companies.

The “Factory of the Future Lab” is a space where automation experts, programmers, maintenance and production staff, as well as technology enthusiasts, can not only learn about Industry 4.0 concepts, but above all test them live. It features solutions that are currently used in the automation of production processes, as well as the latest technologies that will be implemented in manufacturing plants in the near future, according to the vision of Industry 4.0.

Assembly line in ‘Factory of the Future Lab’ / Photo: Bosch Rexroth Sp. z o.o.

Bosch Rexroth develops and implements the most innovative technologies for production automation. Its components are tailored to specific requirements and used to build advanced production machines. The “Factory of the Future Lab” showroom allows partners and customers to test these solutions that may seem futuristic today, but will soon become the industry standard. The facility addresses the needs and expectations of customers who want to explore the potential, power and validity of implementing innovative Industry 4.0 solutions in their facilities”, said Thomas Ilkow, CEO of Bosch Rexroth

New Approach to Programming and Digital Twin

The showroom’s assembly line, known as the “Factory of the Future Lab”, consists of 90% Bosch Rexroth products and software. Key technologies in the facility include automation and robotics solutions such as innovative PLC controllers, industrial computers, motors, linear motion technologies, cobots, as well as IT and artificial intelligence solutions. The showroom also demonstrates the potential of modern protocols by integrating them with the IT world and industry, facilitating data exchange with cloud computing.

Adam Piszczatowski, Industry 4.0 Manager at Bosch Rexroth, highlighted three Industry 4.0 technologies used in the showroom that make it truly unique. Firstly, the use of high-level programming languages greatly expands the possibilities for customers through increased flexibility and openness to web interfaces. Second, specialised microservices in the form of computer programs have been created to exchange information with the production line, enabling machines to communicate with each other and even with products or people without relying on overarching systems.

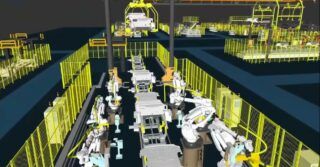

The third key technology is the so-called digital twin, a virtual representation of physical devices. This allows actions to be performed on the real object from a virtual position, leading to better optimisation, extensive testing of prototypes and error elimination. In short, these are the most advanced production automation solutions being used in your laboratory today.

Industry 4.0 not only focuses on optimization but also enhances worker safety

The concept relies on intelligent digital technology to unlock previously untapped machine potential. The benefits of implementing such advanced technologies are numerous, including the ability to detect delays or other irregularities on the production line.

Optimisation efforts, from saving energy to minimising losses, including material losses, directly translate into increased production efficiency. However, Industry 4.0 is not only about efficient production; the use of innovative technologies also enables improved safety and comfort for workers.

The concept of Industry 4.0 includes the automation of many activities, especially those that are repetitive and monotonous. This will allow workers to spend more time on more strategic or creative tasks. As Ievhen Grabowski, Application Engineer at Bosch Rexroth, explains, Industry 4.0 facilitates the continuous improvement of the working environment to make it friendly and safe for people, allowing for optimal integration of human work with machines.

Modern technologies enable improvements such as setting the native language on a monitor connected to a machine, or adjusting the height of a work table. These seemingly simple solutions can make a big difference to daily working comfort. “The most important thing is the safety of the workers. Today, technology offers a range of solutions, such as advanced sensors, that make collaborative robots not only an integral part of modern production, replacing humans in physical, repetitive tasks, but also safer than ever before,” added Grabowski.

In addition to presenting technological solutions, Bosch Rexroth also offers theoretical support to facilitate digital transformation for its partners. Through collaboration, the company conducts customised training to familiarise customers with Bosch Rexroth products and guide them through each stage of implementing production processes using real-world examples.

![Forecasts, Opportunities, and Challenges for the Polish Industry in 2024 [ANALYSIS] Forecasts, Opportunities, and Challenges for the Polish Industry in 2024 [ANALYSIS]](https://industryinsider.eu/wp-content/uploads/xIndustry-40-320x167.jpg.pagespeed.ic.o8zijDQlIJ.jpg)