Production and logistics systems are currently undergoing revolutionary changes, gaining new features and functionalities. We now see production as a holonic system. Machines, robots and products are becoming intelligent, and advanced information and communication technologies are becoming the central nervous system of future production. In the near future, artificial intelligence will take over many management and decision-making functions in production. Production systems will be able to learn from their previous operations.

The virtualisation of processes will lead to the widespread use of sensors in production, enabling the collection of large amounts of data. This data can be processed into information, further processed and used to generate and apply new knowledge.

The new production environment will maintain and manage its virtual image using the Internet of Things and cloud computing technologies. Without intelligent and adaptive production and logistics, companies will not be able to operate efficiently in the competitive environment of global markets.

Future production and logistics systems must above all be adaptive, capable of adapting autonomously, actively and rapidly to sudden and unexpected changes in their environment that go beyond the originally defined functions of the system. Such a system must be able to change not only its structure but also its functions and capabilities.

The fundamental characteristics of adaptive future production and logistics systems include:

- Adaptability: Flexibility limited to the family of elements or products.

- Scalability: The ability to easily change the capacity of the production and logistics system by adding or removing resources or changing reconfigurable elements of the system.

- Convertibility: The ability to easily change the functionalities of existing systems, machines and control systems to meet new production requirements.

- Modularity: The integration of operational functions into units that can be manipulated between alternative production and logistics schemes for optimal results.

- Integration: The ability to quickly and accurately integrate modules through various mechanical, information and control interfaces that allow integration and communication.

- Diagnostics: The ability to automatically detect the current state of the system and its control, to detect and diagnose the causes of equipment or product failures, and to quickly correct operational problems.

Engineering, technological design, planning, management and optimisation of production and logistics processes must respond to these changes resulting from the Fourth Industrial Revolution and the desire to build intelligent factories.

The design, management and optimisation of future production systems will not be possible without the use of advanced technologies. Future production systems must have completely new characteristics such as self-organisation, reconfigurability, autonomy, self-optimisation, self-replication and the ability to learn and work autonomously with the creation and use of knowledge.

The design of production systems involves the use of a wide range of modern technologies. This is now known as advanced industrial engineering. Production systems are now designed in virtual reality, and computer simulation has become a standard element of such systems, with increasing use of artificial intelligence methods.

Our company has been working for a long time on tasks and projects aimed at implementing the methods and approaches of Advanced Industrial Engineering in the concept of the Fourth Industrial Revolution. For this reason, we have created the Twiserion system, which allows not only the planning, monitoring and subsequent management of production and logistics processes, but also the intelligent management of AGV robotic systems in the performance of various logistics tasks.

The Twiserion system, which supports the concept of the digital enterprise, already provides a virtual environment for designing, testing and verifying decisions at various stages of the product life cycle. Its basic premise is to create a comprehensive link between data on products, processes and production sources in a common database. One of the key elements of the Twiserion system is the Design Manager.

Twiserion Design Manager: an interactive system for designing production and logistics systems

The research team at Asseco CEIT has developed a software module called Twiserion Design Manager for the design of production and logistics systems. This tool enables collaborative design of production and logistics systems using 3D models.

It allows production concepts to be easily modified and analysed, with their effects immediately visible in real time. This innovative approach allows design teams to modify production layouts with simple gestures and immediately see how these changes affect the production system.

Twiserion Design Manager provides answers to “What if…?” questions. This tool enables the creation of comprehensive models of production, logistics and warehousing systems using parametric settings. These parameters include physical properties, production parameters and others, on the basis of which the system evaluates monitored indicators. Twiserion Design Manager offers significant time and cost savings to customers in the industrial sector.

It increases the efficiency of the design and planning process by an average of 30%, while reducing total workshop time by 25%. Twiserion Design Manager also improves processes, resulting in average cost savings of 30% in production and logistics

The current standard for designing production and logistics systems is to create flexible solutions in a 3D environment using parametric 3D models of machines, equipment and other accessories. Such models of the production system can be easily and quickly modified, compared and optimised.

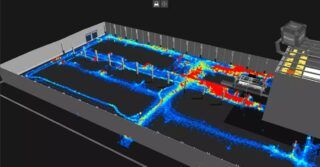

The 3D design process typically begins with 3D scanning or some other method of digitally transforming production spaces, manufacturing equipment and other elements of the system being designed. After obtaining the necessary models, the production layout is designed by placing these objects in the production space. Twiserion Design Manager allows interactive design using static analysis. The designed layout of the production or logistics system is then verified through dynamic simulation.

The final version of the solution can be presented using virtual or augmented reality features, such as avatar functions. However, the concept of a digital enterprise only covers one aspect, namely the digital representation of the facility, which serves as the basis for the next implementation of the physical system and its deployment. However, the physical system requires additional management and optimisation, even during actual operation.

The production and logistics system is a dynamic and open system that must constantly change and adapt to changes in the internal and external environment. This requires the linking of physical system data with its digital counterpart. The concept of the digital twin factory addresses this issue.

By connecting the data model created in the Twiserion Design Manager software with real data collected and managed by the Twiserion Digital Manager system, we can conclude that the Twiserion system fully supports the concept of a digital twin.