It all starts with a vision and then moves on to the design process, which is an integral part of creating objects that accompany us in our daily lives. Today, thanks to generative algorithms, designers can significantly speed up and improve the process of generating different solutions. These algorithms enable the creation, analysis and optimisation of designs in a way that is difficult to achieve using traditional design methods.

By considering multiple variables, criteria and constraints, generative algorithms allow for rapid exploration of different scenarios. Intelligent algorithms not only help to create better products, but also have the potential to revolutionise the product development process.

Modern industry relies heavily on advanced technologies, one of which is generative design. The use of advanced machine learning algorithms and neural networks is the way forward to automatically generate new solutions in various industrial fields.

There is no doubt that generative design is a hot topic that is attracting the attention of many professionals. It is one of the most cutting-edge technologies that really shows the future use of computers, computing power and engineering. Essentially, it is the computer designing something for you – an engineer just has to input parameters into the software and after some time we see the generated design. Such designs look very organic, similar to something created by nature, and that’s no accident.

Generative algorithms are now an incredibly versatile tool that goes beyond the realm of construction and design. They are used in a wide range of engineering fields, including fluid flow optimisation, electrical design, optics and even acoustics. Architects and urban planners use generative techniques to optimise building layouts and urban spaces, allowing for the efficient consideration of multiple design criteria.

The same algorithms are also used to solve complex optimisation problems that go beyond the traditional boundaries of product design. The ability to generate diverse solutions and consider multiple criteria simultaneously makes generative algorithms an excellent tool in today’s engineering environment.

The future of product development

Most product development tasks are complex optimisation problems. Project teams approach them iteratively, refining initial best ideas during engineering analysis. However, each iteration costs time and money, and teams can only go through a few iterations within the development schedule. Because teams rarely have the opportunity to explore alternative solutions that deviate significantly from their initial assumptions, the final design is often suboptimal.

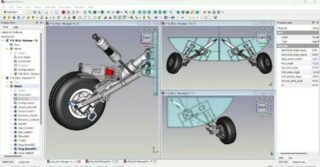

Today’s advanced technology offers rapid digital simulation and analysis. Algorithms can automatically adjust part geometries between successive simulations, eliminating the need for manual corrections. This means designers can dynamically experiment with different shapes and configurations, achieving optimal results in much less time than with traditional design methods.

By using artificial intelligence techniques, modern generative design systems are able to explore a much wider range of possible solutions. For some types of engineering problems, generative algorithms already outperform human engineering teams. With the ability to consider multiple variables simultaneously, they can generate solutions that may be difficult to discover using traditional design processes.

In addition, generative algorithms often have the ability to generate non-intuitive, innovative solutions that go beyond conventional approaches. This opens up new design perspectives and allows the exploration of alternative concepts that can bring significant benefits in terms of efficiency, performance and sustainable development. In this way, generative algorithms become an indispensable tool in the engineering process, supporting and complementing human creativity and design skills.

Currently, the most common application of generative design algorithms is structural optimisation. These algorithms are used to create parts with sufficient strength, stiffness and fatigue resistance while minimising material consumption. Using this approach, designers can optimise the geometry and structure of elements to reduce material consumption while still meeting strength and functionality requirements.

Such applications are widespread wherever weight is an issue, such as in the design of internal components of hand tools (to improve ergonomics), sports equipment (to increase performance), vehicles and aircraft (to reduce fuel consumption or increase payload), or any product where mass is a significant cost factor.

This approach is crucial in the context of sustainable development, helping to reduce raw material consumption and environmental impact.

Generative algorithms are having a significant impact on industries ranging from automotive and aerospace to sports equipment. In these areas, they can reduce part costs by 6-20%, component weight by 10-50% and development time by 30-50%.

An example of the application of this technology in the aerospace industry is its use at Airbus. Using generative design, the company created a new version of the aircraft cabin bulkhead. The new design proved to be not only lighter but also more durable than the previous one.

The initial higher financial investment in production was not a concern, as it quickly became apparent that the return on investment could be achieved in a very short time. Precise calculations showed that reducing the mass of a specific part significantly reduced the consumption of aviation fuel, contributing to the economic efficiency of the project.

One of the key benefits of generative design in the automotive industry is its ability to optimise components for weight reduction. In this industry, the design of lightweight automotive components using this technology combined with additive manufacturing can yield remarkable results. During the development of new vehicles, increasing customer demands for comfort and high safety standards often lead to an increase in the mass of individual car components. To meet these challenges and the resulting increase in fuel consumption, the product development process requires the implementation of complex and lightweight structures. Generative component design is a powerful tool in this context.

This technology can also revolutionise the way automotive components are manufactured. By optimising material usage and minimising waste, generative design can lead to significant savings in the manufacturing process.

In addition, generative design is well suited to advanced manufacturing technologies such as additive manufacturing (3D printing), enabling the production of complex geometries that would be difficult or impossible to achieve using traditional manufacturing methods. By combining generative design and additive manufacturing, automotive manufacturers can produce lightweight, high-performance components more efficiently and cost-effectively than ever before.

The role of generative design in comprehensive product development

Generative design techniques have already proven that they can significantly improve efficiency in real-world applications. However, their full potential will not be realised until companies apply these concepts on a large scale and make them an integral part of their product development processes.

Buying the right software is only part of the solution. Engineers need to know how to use these new tools effectively, understanding both their capabilities and their limitations. Generative design methods can produce creative, non-intuitive solutions, but engineers still need to verify the results through testing or analysis to ensure that the design can be implemented according to the intended process. This human-machine interaction will continue to evolve as algorithms become more intelligent.

The question every engineer familiar with this technology should be asking today is Is this the beginning of the end of engineering as a human-driven creative process?

Generative design is not intended to replace designers, but rather to augment their capabilities. However, looking 20-30 years into the future, it could hypothetically spell the end of the human design engineer’s job. An AI-based programme could potentially replace the work of a design professional entirely, and that may be the ultimate goal of this technology. For now, we are a long way from that scenario. There are many aspects of engineering that go beyond design, such as the selection of materials and their application in accordance with regulations.

It is certainly a tool that we can have in our toolbox at the moment to help us design and develop new parts. Designers still have a crucial role to play in interpreting the results generated and applying their creativity and industry knowledge to the final project.

The challenges of adopting new technology

For product development managers, generative design technology makes the design process easier and more convenient. However, there are several challenges associated with adopting this new technology.

- Knowledge of the technology: Effective use of generative tools requires engineers to understand both the technology and the algorithms. Proper training and skill development within the team is necessary.

- Integration with existing software: Implementing generative design systems may require integration with existing software and tools used by the company. Ensuring that the different systems work together smoothly is crucial.

- Control of the design process: Introducing generative design may challenge traditional design processes. Procedures need to be adapted to effectively incorporate generative approaches.

- Verification and validation: Despite the powerful capabilities of generative algorithms, verification and validation of results are necessary to ensure that they meet specified qualitative and functional criteria.

- Understanding technology limitations: Engineers need to be aware of the limitations of generative algorithms, including technical constraints and ethical issues such as responsibility for AI-generated results.

- Cultural and organisational acceptance: The introduction of new technologies may be met with resistance from employees and management. It’s important for senior management to understand the benefits and effectively manage the cultural and organisational acceptance process.

- Cost and return on investment: Implementing generative design can be costly, both in terms of acquiring appropriate tools and training staff. Companies need to carefully assess costs and benefits to ensure a satisfactory return on investment.

- Data security: The use of generative algorithms often involves the processing of large amounts of data. Ensuring data security and compliance with privacy regulations is critical.

Implementing generative design is a process that requires careful analysis, planning and organisational adaptation. In the coming years, generative algorithms will continue to develop, becoming more powerful, more widely used and easier to use. As computational power increases, the application of this approach can expand beyond part-level design to optimise team workflows, ultimately promoting a comprehensive approach to product creation.

Several leading companies are already moving beyond the pilot phase of generative design and implementing it within their organisations. It is important to recognise that this requires investment in tools, training and cultural change.

Summary

At present, generative design technology is still in its infancy, with different types of computational models being explored for very different purposes.

Expectations are high, leading to the belief that artificial intelligence will eventually provide unimagined capabilities, especially in the area of idea exploration. The application of generative design is constantly evolving, and advances in artificial intelligence and computational models continue to expand its possibilities.

Given the aggressive pace of development in this technology, it is quite possible that within the next few years artificial intelligence will be able to design components of complexity and efficiency far beyond human capabilities in a matter of seconds. As a result, the role of engineers and designers in the design world could be redefined, leading to more innovative and optimised products in various fields.