Recent years have brought intensification of trends dictating directions for the economic development. Striving to achieve environmental goals of sustainable development, a need to economically manage materials and natural resources, as well as rapid growth of the eCommerce sector made digitalisation of production a must.

This way, the so-called fourth industrial revolution (Industry 4.0) that has been going on for nearly 10 years, has become an element for increasing or maintaining the competitive edge in the market, including the packaging one.

Analysts foresee that the European demand for corrugated packaging products will increase by 2 to 4% per annum on a medium-term basis. This trend is associated with expansion of e-commerce, and resultant increase in demand for packaging. Furthermore, it is influenced by new legal regulations and fees associated with environmental responsibility of manufacturers, as well as an increasing pressure of end consumers, for whom an environmentally friendly method of packing is increasingly important.

To keep pace with this growth dynamics, companies manufacturing sustainable corrugated packaging must invest in development of machines and their automation. A good example here are solutions used in Polish factories of Mondi, a global leader in sustainable packaging.

Digitalisation pays back

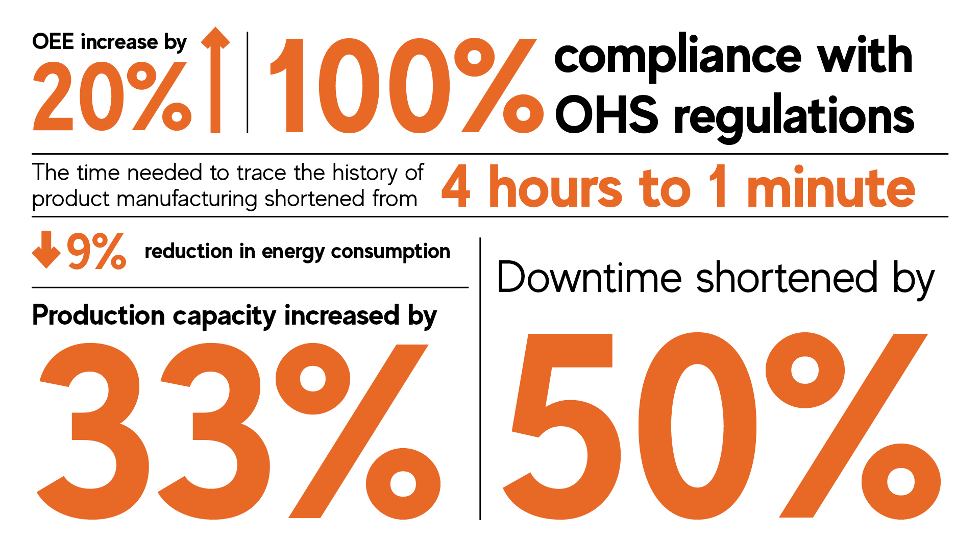

The system implemented by Mondi is based on the Manufacturing Execution System (MES), an application used to continuously monitor production processes and obtain information on their status and quality. This happens in a real time, enabling immediate reaction to undesirable events (e.g., unplanned stops, emergencies, or drops in a capacity).

“There are many benefits of implementing a quality management system”, says Piotr Kożuch, Business Process Owner for Plan to Produce, Mondi Corrugated. “We fully use our production capacities, because we can plan work of each machine in an optimum way. The continuous monitoring of a situation at the production increases capacity of the entire plant and helps to avoid downtime. And with data concerning consumption of utilities and consumables and waste generation, we can optimise raw materials consumption”.

Of course, there are more benefits of digitalisation. At a level of production operators, it is mainly an integration of information required for work in one digital source (instead of three systems and paper documentation). This eliminates a chance for making mistakes, shortens the changeover time on machines, and allows checking a production plan in advance.

At the operating level, this digital solution offers a possibility to manage many stations at the same time, and optimise their actions on a regular basis. The production planning department can, for example, decide about a sequence of implemented orders, to achieve the highest Overall Equipment Effectiveness ratio (OEE) and execute production within shortest time possible.

Current and complete reporting and long-term analyses, on the other hand, are necessary for managing personnel. They can be used as a basis for determining the capacity of each machine, production line, and entire production (current and historical OEE), a number of orders performed punctually, a trend for complaints level, or a level of material losses.

More than just production

Mondi started to digitalise its production over 15 years ago. After over a decade of implementing updates, expanding functionalities, and integration with other systems, the company can proudly boast of its efficiently working applications not only at the shop-floor, but also in production planning or customer service areas.

The Planning Department can view in real time everything that is happening on the production line and observe live a progress in performance of a production order, as well as check an estimated time for its completion. It can also manage machines usage, planned downtime, and deadlines three to four weeks in advance. The Product Development Department can verify and approve first production batches.

With time, the application was expanded with a module responsible for downloading historical data up to 3 years back, for analytical purposes (including benchmarking), while the “Feedback” module is used to verify information from previous performances and causes of lodged complaints. The system is continuously improved in accordance with expanding user’s requirements.

Using the SAP system, it is possible to enter pre-configured settings of an order, on a basis of already performed orders of similar parameters. Soon, the SAP system will be updated, increasing its systemic capacity, and the new S/4Hana module will enable the use of the programme from the browser level on mobile devices and personalisation of interface parameters in accordance with the user’s needs.

Customer in a centre of attention

Furthermore, digitalisation opens new opportunities for the customer service. Company customers have access to the myMondi platform, so they can easily trace a status of their orders and complaints, generate invoices, or verify stock levels. With this solution, customers can also renew orders and place new ones.

The system will automatically check for them whether stock levels and machine usage allow their performance within the required time. If it is not possible, the Customer Service Department can check the soonest possible date using the Capable-To-Promise (CTP) functionality. Works are being conducted to directly connect MyMondi to CTP, enabling complete automation of the order placement process.

In accordance with the Industry 4.0 assumptions, digitalisation of processes in Mondi concerns not only optimisation of systems for control and reduction in consumption of energy and raw materials, but also a comprehensive approach to the work and production organisation. This way, production capacity of each factory can be increased and quick order performance can be ensured. This also improves flexibility and speed of adopting products to customer needs and market conditions.

Looking forward

Implementation of new technologies also has a wider dimension. To increase your competitiveness, you need appropriate facilities with which the company achieves high quality and stability, and can ensure security of supplies for its customers. Furthermore, you need knowledge. Not only about needs or the way of thinking of customers, contractors and suppliers. It also means an awareness of dynamic changes occurring in the market and good understanding of actions needed to use appearing opportunities and addressing threats.

Therefore, Mondi invites you to an extensive discussion on the future of packaging. It covers a series of events, including webinars and cyclic workshops in co-development, at which we check various perspectives of business practitioners, structure our knowledge, and search for new concepts meeting the business challenges.

If you want to keep your finger on a pulse of trends shaping the packaging market, read opinions of experts in this sector and learn how to prepare for approaching changes, visit the following website: https://mondinewsletter.gr8.com/

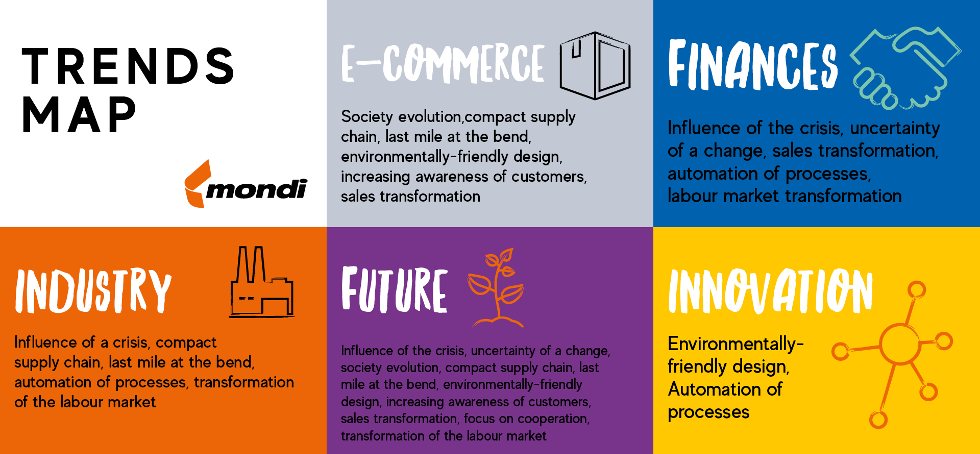

The map of current market trends can be found at the above website.

Below, we present that part of it which concerns this article.