Expanding and modernizing a plant is no easy task, especially when aiming to maintain continuous production. The Rockwool Group managed to achieve this despite disrupted supply chains during the pandemic.

How did the implementation of the LED lighting replacement project unfold in practice?

The primary goal – to reduce energy consumption and CO2 emissions

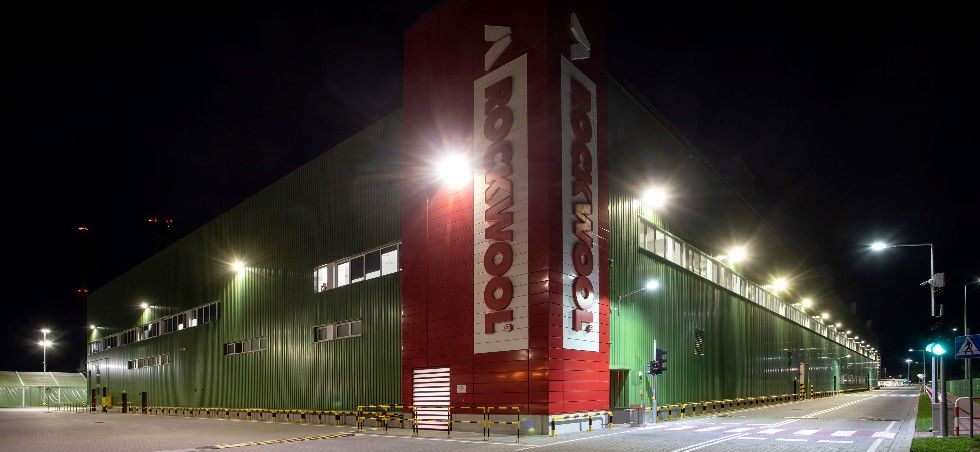

The expansion of the Rockwool facilities in Cigacice began in 2018. The project included the construction of an entirely new, modern hall and office building, as well as the modernization of existing facilities. The implementation lasted for three years and was completed in 2021, just before the outbreak of the energy crisis.

The Rockwool Group prioritized the energy efficiency of its buildings. The outdated lighting required a thorough overhaul not only due to high operating costs but also for the comfort of the employees.

Implementation of LED technology

The Rockwool Group decided to abandon conventional lighting in favor of LED technology, not only for energy savings but also due to the growing capabilities of this technology. Not everyone is aware that:

- Modern LED lighting excels in reproducing daylight parameters, effectively mimicking its color temperature and daily dynamics. It can shine with varying intensity throughout the day, similar to the sun.

- LED fixtures can be integrated within the intelligent Interact Industry control system to automate their operation and gain access to data on their performance, including energy consumption.

- The Interact Industry intelligent lighting system can be expanded with various sensors. In industry, motion sensors and daylight sensors are commonly used to monitor natural sunlight and adjust lighting conditions inside the production hall accordingly.

It’s easy to imagine that all these solutions contribute to additional savings. Simply replacing conventional lighting with LED can reduce energy consumption by around 50%. When we additionally integrate lighting with the control system, we gain an additional 30% in savings, simultaneously reducing the company’s carbon footprint.

Equipping a warehouse of approximately 35,000 m2 with intelligent lighting can save up to 519 tons of CO2 per year (assuming a lighting time of approximately 6000 hours).

These are official but averaged data. A more precise picture is provided by analyzing the effects of lighting modernization in specific examples. Let’s take a closer look at the data from Cigacice, where the Rockwool headquarters is located.

Energy consumption lower by 80% in the Rockwool factory

The installation of LED lighting at the Rockwool facilities in Cigacice took place in two stages. The first stage involved the modernization of lighting in the existing facility.

Approximately 10,000 worn-out conventional fixtures were replaced with modern LED fixtures (Philips LED GentleSpace and Pacific inside the building, and LumiStreet and ClearFlood outside). Later, LED solutions were installed in the newly constructed plant and office building.

All fixtures were integrated into the Philips Dynalite system, allowing remote control and automation of the entire installation, enhancing energy savings.

Photo: Signify

It’s worth adding that some fixtures were produced using 3D printing technology, which found application in the Rockwool office building. 3D printing allowed for the customization of lighting to meet Rockwool’s individual needs.

The decision to invest in this technology further reduced the company’s carbon footprint. This is because Philips MyCreation fixtures are 3D printed from recycled materials (such as old fishing nets) suitable for reprocessing.

Let’s get to the heart of the matter, the savings achieved through the investment:

- In the building renovated in 2018, energy consumption decreased by 55%.

- In the newly constructed facility, energy savings exceeded 60%.

- In the office building, energy consumption was reduced by a remarkable 80%!

CO2 emissions, on the other hand, decreased by 3,500 tons per year, equivalent to planting trees across the entire Tri-City area.

Photo: Signify

Only and nothing but lighting

The role of lighting today goes beyond simply increasing visibility. The recent modernization of the Rockwool plant is an excellent example of this. When we look at the installation from a broader perspective, it turns out to be an ideal place to locate various types of sensors.

Currently, these are motion and daylight sensors whose task is to optimize energy consumption in the factory. The wired Philips Dynalite system and wireless Interact Industry are ready for the implementation of even more advanced solutions.

The expansion of the lighting system can proceed in two scenarios:

- The company can independently implement new solutions, based on its own investment in products and systems that meet its current needs. The company can pay for lighting as a service based on expected and defined outcomes (Light as a Service). In this case, the lighting provider is responsible for designing, delivering, installing products and systems, as well as maintaining the entire infrastructure in the appropriate condition within the contracted time.

- The second option is a good solution for companies that do not have a large budget for lighting modernization but see a high potential for increasing electrical energy efficiency. Investments made in the Light as a Service model are financed from the savings obtained as a result of switching to LED lighting and implementing an intelligent management system. Given current energy prices, these are substantial amounts that usually completely cover the cost of the service.

In the Light as a Service model, the investor, during the contract period, does not become the owner of the lighting but rather leases it from Signify or another service provider. The ready-made solution meets all necessary standards and ensures the highest quality of light. However, the client does not have to manage it independently.

Maintenance and ensuring the highest efficiency of the installation are the responsibilities of the service provider. As a result, the company does not have to delay modernization due to a lack of funds. Instead, it can enter into a long-term agreement with the lighting provider and pay for the service with money saved through increased energy efficiency. Such an arrangement is suitable not only for both businesses but also for the planet!