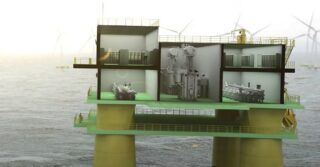

Zamet Industry is known primarily as a world-class manufacturer of devices and construction for the offshore sector – industry associated with underwater oil and gas extraction, as well as for steel metalling and non-ferrous metals. However, the source of its competitive advantage on the market is to a great extent the complementarity of the offer that owes the cooperation of Zamet Group plants.

Zamet Industry is a Capital Group that operates in the large-size steel structures and machines and devices for various industries. The company’s offer is complemented by a wide range of machining services, welding and anti-corrosion protection. The Zamet Group is known to its counterparties as a world-class manufacturer of devices and structures for the needs of the offshore sector and steel metalling and non-ferrous metals.

The unique competence of the castle in the offshore industry was confirmed, inter alia, awarded by the DNV GL Polish certificate to meet the requirements of ISO / TS 29001: 2010, which was received in 2015 – as the first in Poland. This standard defines the quality management system in the organization and the use of the highest standards requirements for suppliers in the field of services and products produced for the needs of the oil and gas mining industry and petrochemical products.

“However, the offshore industry is not everything. Zamet constantly develops its competences in other heavy industry sectors, also in the energy and infrastructure sectors” says Jan Szymik, vice president of the Management Board of Zamet Industry SA – a parent company in the Capital Group.

Group’s potential

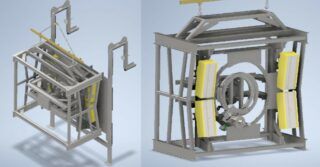

The strength and market competitiveness of the Zamet Group is primarily a complementarity of its offer, which consists of the production capabilities of four plants. The dominant entity in the Capital Group is Zamet Industry SA. This company is primarily characterized by the unique quality of special processes that are used in the plant located in Piotrków Trybunalski. These are processes such as welding and anticorrosive protection that require the implementation of specialized technologies taking into account regulations and standards more demanding than ISO standards (DNV, ABS, Lloyd’s Register). In addition, they must meet the requirements placed by global recipients, among which there are tiders such as Statoil, Total or General Electric. The constructions produced in the Piotrków plant are additionally equipped with hydraulic and electrical systems, and their FAT assembly and testing are carried out on-site, in a production plant.

In turn, the Mostostal Chojnice plant operating within the framework of Zamet Industry SA offers the possibility of making large-size welded constructions. A strong point of this plant is adaptation to produce heavy construction. The plant lifting allows you to transfer the structure with a unitary weight reaching up to 64 t.

The Chojnice plant has, supported by references, extensive experience in the production of bridge infrastructure, viaducts and footbridges, as well as energy, industrial and infrastructure construction. In the portfolio of this plant, there is, among other things, the construction of a steel millenium bridge in London, a roof structure for the Stade de France stadium in Paris or the construction of the Canadian Human Rights Center.

In turn, belonging to the Zamet Zamet Group, the construction of machines SA and operating in its structures The Huta Zygmunt plant in Bytom is primarily characterized by a strong structural office. The machine park is the main potential of the Zamet Industry Castle Machining Capital Group.

The weight of the workpiece in the Tarnowskie Mountains of Elements may reach 150 t. The company performs all elements of mechanical and thermal treatment, including Turning on carousel lathes at turning altitudes up to 4000 mm and rolling diameter 11000 mm

Zamet Machine construction has many years of experience in the production, service and modernization of machines and the introduction of solutions for various industries.

High specialization

Each of the mentioned plants play a very important role in the structure of the whole group: “The key to success is a high specialization here in the implementation of specific tasks. A huge manufacturing potential of the Zamet Group decides that it employs about 1.2 thousand. Employees with high qualifications and a wide spectrum of competence” – adds Jan Szymik.

What’s more, the plants and employees complement each other and cooperate with each other, which gives a group of huge potential and the possibility of performing even very complex and complex orders. The company has implemented cooperation and communication mechanisms in its production plants, thanks to which the synergy effect was achieved within the Group. And this allows for effective cooperation in many areas of production and systematic building position on the market. Cooperation within the group also allows flexibility in activities. Thanks to this, the Zamet Industry can adapt to detailed requirements of its clients.

And this in turn translates into the fact that Zamet is a partner often chosen by both domestic and foreign contractors who, on the one hand, are looking for solutions tailored to their needs, and on the other hand, they expect a guarantee of reliability of services offered. The competitiveness of the Zamet Group also shows from the fact of production plants. They are located throughout Poland, which allows you to locate production in a plant that has an optimal location in the context of transport options to the destination of large-size structures.

An important action that the Management Board of the Company recently has been made by the Zamet Industry is long-term cooperation with one of the Tri-City business partners, in terms of guaranteeing access to the Baltic Seafront

Let us add that the Zamet group belongs to the Polish private investment company TDJ SA, which is the property of the domogal family, which operates in many sectors of the economy, and in its investment portfolio it has 16 industrial plants, including entities such as Poland Foundry Group SA, Famur SA, Famur Famam, FPM, Fugo Group. Thanks to this, the zamet has unique opportunities for cooperation between related entities belonging to TDJ SA.

Developmental cooperation

An important aspect of the Zamet Group’s development plans is to invest in the development of competences – both at the level of organization and individual employees creating the company’s community. It is not only about the implementation of the Group’s action philosophy, but also to apply the highest international standards in the scope of services (confirmed by multiple certificates of recognized international certification bodies, including the DNV GL certificate in the field of ISO / TS 29001: 2010).

An important action that the Management Board of the Company recently has been made by the Zamet Industry SA with long-term cooperation with one of the Tri-City Business Partners, in terms of guaranteeing access to the Baltic Seafront. As a result, the Group obtained the possibility (at least until the end of 2017) to implement projects on the waterfront with appropriate conditions. It’s about the right load capacity and pool parameters: depth and navigation conditions. All this enables the implementation of large and demanding projects here. An example of such a structure is weighing above 2 thousand. T Shiploader, i.e. a port loading device having 150 m long, 10 m wide and 50 m high, which the Industry Zamet carried out in the years 2014-2015 to ThyssenKrupp Industrial Solutions.

This machine that can transport 11 thousand. T iron ore per hour, eventually hit the Norwegian harbor in Narvik

Zamet Group Development Plans

Listed on the Warsaw Stock Exchange, the Zamet Industry SA has a stable financial situation and credit and acquisition capabilities, thanks to which it can quickly respond to the changing market situation and possible investment opportunities. One of the investment that the company is interested, is the Aquifies of Fugo Sp. From O.O. Based in Konin. The acquisition of this plant would increase the generation capacity of the Zamet Group, especially in the area of the infrastructure sector, and additionally would supplement the competences of the group in the field of lifting devices.

In March 2015, the Company signed an agreement with TDJ SA and Equity III TDJ Finance Sp. From O.O. SKA, thanks to which until the end of 2017, the Industry Zamet has an open option to purchase a hundred percent of shares in Fugo, while ensuring financing this investment from funds obtained from investors. The acquisition of Fugo is not the only investment that the Zamet is interested. The company with interest is interested in entities with competences in the field of designing in the infrastructure segment. Increasing its competences in this respect would allow to strengthen the position of the Zamet Group and its further development on perspective markets.

New market areas

Each of the plants, which belongs to the Zamet group, has significant references and experience on a wide range of steel structures and machinery and equipment for the industry. For example, a significant part of the structures produced in Piotrków Trybunalski goes to foreign recipients who are global leaders in providing solutions for the industry related to the exploitation of surgical oil and gas. “Nevertheless, we see significant growth potential for Mostostal Chojnice, taking into account the perspective of the infrastructure construction market. This plant specializes in the manufacture of heavy steel structures of industrial, energy, sports facilities and other buildings and buildings – footbrades, bridges and viaducts” says Jan Szymik.

Power of the machine park

Machine park and resources suitable that the Zamet Group’s potential is certainly one of the largest in Poland. The production area of the Group’s plants is over 118 thousand. m2. Each of the plants belonging to the group is equipped with modern equipment enabling orders for the manufacturing sector of large-size steel structures and machines and the provision of high-quality machining services, welding or anti-corrosion protection. The Industry Zamet equipment includes, among others, Numerically controlled drill and milling machines – Juaristi and Union machining centers, carousel, train and disc lathes, gantry milling machines and envelope.

The equipment of the machine park is also a blast chamber and fully automated painting cabins (50 × 5.8 × 5.8 m), enabling automatic adjustment of working conditions, with the possibility of dividing to segments. The plant is also equipped with a modern “pure assembly” hall and a assembly site along with a test tower. Tarnogórski plant is equipped with, among others Numerically controlled machines and heavy machine tools, including: drilling and milling machines for processing element with dimensions of 5 m high, 16 m depth, 16 m long, lathes with a turning diameter of 3 m and many lengths, as well as gantry milling machines, envelope and many more machining machines. “During the implementation of complex projects, all Zamet Group Zakłady cooperates closely with each other. Thanks to this, we obtain a synergy effect on many planes of activity” says Jan Szymik.

Not only offshore – a conversation with Tomasz Jakubowski, president of the board of Zamet Industry

The first association with the Zamet Industry brand is, of course, offshore, meanwhile, has long been under the development of a great emphasis on the development of the Zamet Industry group. How important are these two areas of activity?

Association of the Zamet Industry with a company operating on the offshore market, which implements contracts for the largest global recipients on the device market for drilling platforms and for underwater oil and gas extraction, is right. On the one hand, it is supported by a significant share of this segment in our activity, but above all is related to the high competences of the Company on this market that translate into a wide recognition of the ZAMET brand in the world.

Our company is not only offshore, because we have no lower competence in the production of machines and devices used in shipbuilding, metallurgical, metallurgical, food, energy and – what we want to emphasize – in the bridge and industrial infrastructure industry

We have extensive experience and all necessary competences that allow us to be an attractive construction supplier in the developing segment of energy and infrastructure. A good example includes a recent contract with a value exceeding PLN 35 million net, implemented for the benefit of RAFAKO SA, in which the Zamet Industry will perform and will provide a load-bearing steel construction with a carrier grate for the construction of a 910 MW energy block in the Jaworzno III power plant. We will strive to cooperate with our partners in the field of similar implementation, constantly deepened. We see significant potential for this market.

What, in your opinion, are distinguished by the Zamet Industry group from the competition? What is the most competitive in Poland, in Europe and in the world?

The competitive advantages of the Zamet Industry Group are mainly based on our reliability, extensive experience and complementarity of the offer of production plants included in the Group. Individual plants are characterized by a high specialization in the implementation of specific orders for our contractors, while combining them within the Capital Group allowed to obtain the effect of synergy and complementarity of our activities.

The attractiveness of our offer is intended by mutual supplementing this offer and the implementation of effective communication mechanisms, allowing cooperation in individual areas of production, as well as proposing a unique offer tailored each time to specific customer requirements. An important factor increasing our competitiveness is also the geographical location of our plants. The fact of deploying them throughout Poland allows you to locate the production process in the optimal site from the point of view of transporting structures to the place of their destination.

How do you evaluate the Polish Steel Construction Market? Is this a development market? What does it look like other countries in Europe and the world?

Each subsequent contract signed by the Zamet confirms us that the Polish steel structural market will be one of the most promising in Europe. Our country has passed through the financial crisis mildly than other European Union markets, and the Polish economy is located all the time on the growth path, which translates into investments in infrastructure and residential construction. This situation allows a stable increase in the number of steel structures produced.

In addition, the production volume of steel structures in Poland makes one of our country of major players in this market in Europe. Since 2010, the export of Polish steel structures increases, and Zamet is a frequently chosen partner by foreign contractors. Undoubtedly, the recognized quality of the products we offer and extensive possibilities to prepare an offer corresponding to the specific requirements of customers.

In what direction you plan to develop the Group’s operations in your coming years?

Due to the current situation on global energy commodity markets, which does not conduct the development of investments in the field of submersible oil and natural gas deposits, we will further diversify sources of revenues even more than before. The goal of the group is stronger to mark our presence on the infrastructure, energy and industrial market.

Everywhere, we have all competences and experience to pursue complex large-scale investments. Of course, the above actions do not mean resignation from the offshore market. We want to sustain our competences in this sector, so that when the economic situation on the market stabilization is prepared for a quick return to high order volumes. What’s more, our potential and existing experience allow us to introduce more and more attention to perspective markets at this point.