Serial production of yachts built for individual order combines with large investments and a high price that will ultimately pay the potential buyer. President of Aquila Yachts – Experienced designer and sailor Krzysztof Maćkowiak – found a way to reduce production costs, and thus, prices of such yachts, without giving up quality.

Family sailing traditions

Krzysztof Maćkowiak was born in a sailing family. His father – a ship and yacht designer – often worked at home on a drawing board. “I always assist him – Maćkowiak recalls. – Since childhood, he taught me models, drawing and quick sailing. When I was 10 years old, Dad built his first yacht. I was on the construction site, and he always allowed me to spoil something. Since childhood, I often have been in the Płock shipyard, and my dad patiently and easily explained the secrets of ships and technology”- he adds.

In the 1990s, Krzysztof Maćkowiak worked in the first in Poland a well-stocked sailing store, who sold West and Russian accessories up to 80% of newly emerging sailing stores. There he acquired skills in moving in the world of Western market, supplies and equipment manufacturers. For a sixteenth year of life he designed and built yachts together with his father. “Dad wanted traditionally, and I was looking for a noveltis in the easy-earned western sailing magazines, for hours, I analyzed photos of more interesting boats – says. – Later, in student times, I was building yachts myself. To maintain, I created twenty” – says. After graduation, he started a few years of work in the Gdańsk branch of the Wrocław Project Office Navicentrum, he designed inland vessels and rode to supervises to Wisła shipyard, shipyard in Tczew, Nauty and War Navy Shipyard in Gdynia. “It was a good ship construction school – assesses Maćkowiak. “Later, the adventure with large ships of Mr. Zygmunt Chorenia began, who was my second important teacher and guru from great sailing ships” he adds.

Krzysztof Maćkowiak also worked in the Bureau of Projects in the Netherlands, in a yacht company in Germany, he designed and supervised the reconstruction of a large yacht in Turkey. He still sails and organizes the regatta.

In 2010, he patented the innovative technology of building units floating from polymer composites from which he intends to use in the near future. This technology allows you to reduce production costs by deforming ready-made joined yacht shells along with the entire interior design, with integrated door frame frame, windows and vulnerabilities and other details that have to be performed and fit separately.

Super yacht Aquila 75

As a result of many years of experience and inspiration during work in Greece at a 16-meter marched yacht, Krzysztof Maćkowiak appointed Aquila Yachts Sp. From O.O. It was mainly created to implement a more-scale superjot project and soon turned into a research and development company focused on creating and implementing innovative technologies and new materials for the construction industry of large yachts and small ships. “From a small office in Rotmance near Gdansk, we moved to the shipbuilding hall with the waterfront in Gdańsk – says. – We have created a design and technological office, we employ 19 people and we cooperate with several subcontracting companies, mainly with Janmor yacht yacht yacht andrzej Janowski from the Głowna Koło Łódź and with my mother design office Design & Consulting Zygmunt Chorenia. Steel constructions were carried out mainly by Yachtmetal Andrzej Ebony from Pleszew K Kalisz. We also cooperate with a large machining company in Germany” – calculates Krzysztof Maćkowiak.

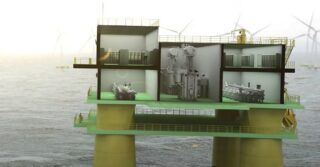

As a result of research and development works as part of the project co-financed by the European Regional Development Fund, the Company launched the Aquila 75 Superjot project. There were several yacht projects of 75-80 feet long and many innovative technologies based on different modular systems. On the basis of one hull designed with emphasis on the maximum comfort and safety of rapid shipping in heavy stormy oceanic conditions, several competing and original projects were created: Sailing superjections with a hundred interior design and the possibility of diversified external architecture, oceanic motor yacht with similar interiors, scientific and research sailing ship Also designed for treasure experts from immersed wrecks, a small coastal or inland passenger ship and a project of a school sailor in a traditional version and in the form of a prototype being built – a version of the integration and school-touring sailor for young people and people with disabilities. Each of the projects – thanks to Aquila Yachts to innovative technologies used by Aquila Yachts – offers users to adjust the functional functions, attractiveness and designing architectural forms at an affordable price of a regular yacht.

Integration and modularity

Yachts of Aquila Yachts, unlike most competing yachts, are designed for a wide group of users thanks to the integrated project for a comprehensively optimized hull. “The projects of the Company were created as a study of all possible interiors for each potential user – says Krzysztof Maćkowiak. – Aquila Yachts offers the future user with independent (with the designer’s assistance) to compose the interior of a yacht based on the available interior design system. In this way, with an almost individually composed yacht of any interior design, it manages to keep the price of a yacht built in series, which is significantly lower than the price of the yacht built for individual order” – explains.

As part of the Aquila project, several significant innovative technologies for the construction of large floating units have been created, materials used in military aviation, but above all, studies and simulations of the needs of all potential users of yachts were carried out – from affluent and very demanding to the immicular youth looking for their place in the complicated world and people With organism dysfunctions, which active sailing gives a sense of better use of his life. “It started with understanding the idea of modular systems thanks to in-depth explanations of a certain American professor fascinated by the modularity of the world of nature and technology – says Krzysztof Maćkowiak. – Later we have developed a polymodules based furniture system. Then we designed bulkhead divisions, height schemes and several basic interior layouts. After adjustment height of the hull has been designed almost all possible interior layouts with the assumed bulkhead division and the division of the height of the hull.

There were more than 90 versions of the interior designed for various potential groups of super superjet users. Nobody still did it in the world!

In our polymodular interior layout, we had eight different cameras layouts in five different regions of the hull, multiple toilets smaller and larger in many alternative places, shipowners on the stern or before the male and smaller or larger hospitable and crew cabins. For this different places for economic rooms, laundries with ironing rooms and sail storage in several sizes, and finally several versions of skipper-crew cabin for charter yachts. We emergently learned and considered the habit of British, Scandinavian, Mediterranean and American sailors and the requirements of exclusive charter companies, as well as trends in the luxury hotel and household. Our Credo was to create a superjot, where the view of potential customers gave up the purchase of every other yacht competition” – sums up.

As a result of many years of design and research works, there was a secure wave sailing, a packaging hull with low resistance and as high comfortable parameters, optimized both for shipping under sails on the rough sea, as well as to navigations with motor drive as an oceanic buoyancy of a long-range motor yacht. The hull in question is also perfect for a coastal or inland passenger ship, and finally on a sailing school ship with a rock sailing. “In addition to the special structure of the hull, enabling the use of a leading polymodular interior design technology, we have developed and implemented new modulated technologies on both hydraulic and electrical systems as well as forming systems for the production of large-size composite structures, based on 3D modeling and various types of CNC machining” – informs Macowiak

Sailing ship for children and disabled people

During the implementation of the Superjanite project, the idea was created to build on the same hull a slightly other yacht, not for very affluent people, but for the developing youth. This was how another project prototype of a school sailing ship and a new claiming version for the modern idea of sailing youth training in weekly cruises in the Mediterranean, held throughout the school year under the so-called Green school. “As a result of many conversations with the president of the Empathy Foundation, Andrzej Walczak, the shipowner of the Jacht’s Empatia Polska supervised, on which people with disabilities and a person from the age group 50 plus were sailing, the next idea of designing a special tourist and integration sailing ship for people with disabilities – says Maćkowiak. – The sailing ship is designed for 29 people: from three to five people of professional crew (including two physiotherapists) and 24-26 people of the school crew, including 12 people moving on wheelchairs”- sums up.

A man moving on a wheelchair can be almost everywhere and actively participate in life and work on a sailing ship. It can control, handle sails, work in the Cambuzie and move around the whole board: from a bowl of the bows, after a wide bukzprite, up to the rack on the stern. After the exit elevator to the lower deck and crossing from the crew speech for the stern waterway, the water sports deck can easily, independently or with assistance, take a bath in the sea. “In the future, we plan to cooperate with the Gdańsk University of Technology for the equipment of a sailing ship in devices to control blind persons – says Maćkowiak. – Within a green school, we can offer cruises for the entire class with 2 or 3 teachers from a given school” – he adds. The company in cooperation with professionals plans to prepare a special weekly curriculum during a cruise. It has to include school items taught in gymnasium and high school, but in a slightly different aspect – so they will, among others Physics and sea biology, vocabulary related to the sea in foreign languages, maritime literature, geometry and navigational astronomy, and even history of the development of civilization in the aspect of shipping and marine battles.

Large forms

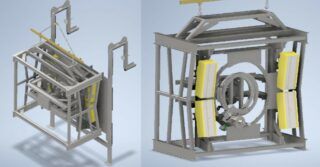

During work on innovative technologies, Aquila Yachts has developed new forms for the construction of large-size composite elements, offering customers the production of modern systemic large forms for composites based on 3D design technologies and CNC machining technologies. “We are probably the largest” Civilian “largest” Civilian »Milling Form of the Hull with a length of 24 m and a width of 6.5 m – says Krzysztof Maćkowiak. – The modular division of forms of beads based on tangential spherical surfaces enables construction of significantly larger composite hulls of fast and efficient floating units with liquid shapes, both sailing and motorized, length up to 40 m and width up to 8 m” – explains. An additional innovation of the form system is to laminate the hull together with a deck in one process as a uniform shell. The combination process on the edge of the side and deck is passed, which increases the strength and durability of the hull and eliminates the difficult process of fitting and connecting the huge shells of the hull with a deck.

System approach

Modular and systemic thinking of the Aquila Yachts design team has potential in many areas – projects of yachts and furniture have already been created, and in the future the company intends to enter the construction market. In the following years, Aquila Yachts plans to conduct research and technological work in new directions related to shipbuilding, a composite industry, but also with the construction of system houses. Research is conducted at the Faculty of Ocean Engineering and Shipbuilding Gdańsk University of Technology with Dean of prof. Janusz Kozak and the Cathedral of the Chemical Faculty composites under the direction of prof. Józef Haponiuk, where three engineering works based on innovative technologies of the Company are currently underway. Currently, comparative studies of glass and basalt composites at the level of atomic microscope are currently being carried out. The company plans to implement modular technology also to build multi-storey houses construction, with possible sophisticated decorative elements. “In this system you can easily play historic houses with decorations or create new, fancy building shapes, unattainable using traditional technologies” – sums up Maćkowiak.

Restore the shipping Vistula

In addition to the superjachet project – in response to the enabled revitalization program of the Wisła River – Aquila plans to build prototype Wiślane hulls, as well as tests and implementation for production. The goal is to restore the Wisła River as soon as possible to a state that allows normal shipping. The inland ship with its own drive is to enable easy descent from my own strength. “I am sailing after the Vistula from 10 years of age and from time to time I come back to my beloved River – Maćkowiak tells. – In childhood, when it fires well, I raced on a yacht with steam baconoloves, and later with more modern passenger ships and pushed sets, designed and built by my father. Now all of the Vistula is dead when it comes to navigation. I often stay over the Rhine, Mozelą and over the rivers in the Netherlands. There, the ships swim almost one after the second, both sides” – explains Maćkowiak.

According to Maćkowiak, the shipping is cheaper than road and rail transport, requires much less fuel and is more ecological. “After the events of August 1980, the Polish state forgot about the existence of water transport and the need to maintain rivers in the right technical condition – Maćkowiak talks. – Polish rivers dry out, the level of groundwater is reduced, the soil steps, decreases agricultural yield levels. Above all, however, it almost completely froze the commercial and passenger shipping on the Vistula and smaller rivers. During frequent travel by car along Wisła, my wife – which also navigates – she urged me to come up with a new ship that could swim on a very shallow river. Then I came up with a DNA system and cooperating propulsors that enables self-leaving of the ship from the middle.” Currently, Krzysztof Maćkowiak together with the team develops innovative technologies for the construction of a new type of ship with a hull, which will be able to serve both selling and passenger ships.