Back in the 80’s, they were the main supplier of electric motors for radiators, heaters and wiper units for car windows produced in Poland. Today, they specialize in the production of motors and drives (mainly for the furniture industry) and in the electroplating of metal elements, as well as ABS plastics. Many years of experience mean that the family business from Duszniki-Zdrój aims higher and higher. “There is no room for stagnation,” says Andrzej Banaszewski, president of the management board and co-owner of Zakłady Elektrotechniki Motoryzacyjna.

Zakłady Elektrotechniki Motoryzacyjnej in Duszniki-Zdrój is a company with extensive experimental facilities in the field of production of components for the Polish automotive industry. In the 1980s, ZEM was the main supplier of electric motors for coolers and heaters as well as complete windshield and rear window wiper units for passenger cars (PF 125p, Polonez, PF 126p), vans (ŻUK, Nysa, Tarpan, Polonez Truck), and trucks (Jelcz, Star) and buses (Autosan, Jelcz). Back in the 1990s, ZEM produced complete wiper units with blades for Daewoo cars at the time of its glory and assembly in Warsaw’s Żerań. ZEM was also a leading supplier of electric motors for heaters and windscreen wipers for cars manufactured in FSM Bielsko-Biała, and then in Fiat Auto Poland (PF 126p, Cinquecento).

Today’s ZEM is not the same

Over time, ZEM has changed the area of activity a bit. However, it still remains largely in the automotive industry. Currently, the family business from Duszniki-Zdrój focuses on production activities in the field of low-power DC motors for various applications in the furniture industry (e.g. for electric adjustment of the height of table tops, tables and armrests, for lifting and leveling hospital beds) and in the automotive industry. (drives for car wiper units, heaters and fans).

It also specializes in electroplating metal parts (coatings: weakly acid zinc, very durable coatings: zinc-nickel in the drum technology, coatings: alkaline zinc in the suspension technology) and plastic parts (ABS or ABS / PC) – copper-nickel coating – chrome, including a specialized finish for the MPS and PNS automotive industry in suspension technology. The most interesting for the company are the possibilities of continuous improvement through the modernization of products and their development in cooperation with contractors. “Thanks to the rapid development on the market and the growing demands of customers and consumers, there is no room for stagnation. All this allows us to develop and drives us to act, in line with our slogan: Together we drive the future” says Andrzej Banaszewski.

At present, the company employs approx. 200 people, all under employment contracts. 60% of the staff are people responsible for the assembly of products and the provision of services (production employees), 40 people are responsible for technology, product and process development and quality control. “We invest in our employees and we give the opportunity to develop ourselves and the company, for example by paying for and participating in training courses or even through the in-house program” I have an idea “. Those willing can also count on co-financing for studies in line with the company’s needs, ”emphasizes the president of the company’s management board.

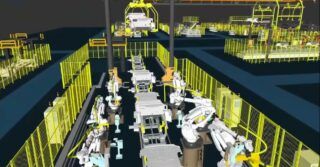

The plant covers a total area of about 4 hectares, the vast majority of which are production buildings. “Our production is very flexible, we invest in more and more efficient machines to improve production efficiency and customer satisfaction with meeting all requirements and deadlines” – says Krzysztof Mikrut, director of technology and development, and emphasizes that the most important for the company is the quality of products, their reliability and adaptation to individual, specialized customer requirements. “Customers often ask for components for their vehicles that were produced 20-30 years ago and are only now starting to fail. They find our traditional, unchanged logo for many years and ask us for the current price for a given product or the possibility of purchasing a replacement in ZEM” says Magdalena Kubiak, marketing specialist.

Despite not too much capital, characteristic of family businesses, ZEM is constantly trying to create and implement new solutions in the world of technology. For several years, it has been providing know-how and machinery as part of cooperation with the Wrocław University of Technology and local scientists.

Drives for furniture and doormats

The company currently focuses largely on the production of electric motors and drives for the furniture industry, because it is in this industry that it records the greatest demand for its products. The motors are produced in the 12V – 24V versions and their power is up to 50 W. After installing the appropriate gear, the power of up to 16 Nm can be obtained on the wheel shaft. The drives are used for linear actuators that can lift the chair footrest, chair backrest or table top. The company also produces motors for narrow table legs, in which the entire actuator must fit.

Strategic partners are German companies from the furniture industry that purchase electric motors for their linear actuators. As Magdalena Kubiak says, it is a cooperation based on many years of series of products of one type, which are refined by both parties (the contractor and ZEM) in such a way as to meet the high expectations of end users. “The cooperation is based on the initial assumptions on which the development and technology departments of both companies worked. We work on the basis of long-term framework contracts, which, on the one hand, allow us to keep the price, and on the other hand, guarantee the occupancy of production and a predictable future in terms of, for example, the purchase of components and materials” he adds.

These drives are also used in the automotive industry, mainly in engines for windshields of passenger cars and buses, as well as in mining or agricultural machines and special construction machines. The smallest ZEM motor weighs approx. 400 g and is 7–8 cm long, and the largest one – approx. 5 kg and 25–26 cm long. Depending on the customer’s requirements, the motors and drive mechanisms can be equipped with an LC filter to eliminate electrical noise generated by the motor, a Hall probe system that allows you to control the motors in the application, and thermal switches. The design of these products allows for the use of various types of connections according to customer requirements.

Chrome plastics

A major investment of the company has recently been a return to the automotive industry by providing metallization services of ABS plastics, such as chrome logo, strips, ventilation frames, etc. “We have more and more inquiries about the coating of ABS plastic elements. We notice that the technology of coating plastics with chrome is beginning to enter the markets related to everyday equipment such as vacuum cleaners, refrigerators, washing machines, while recently chrome elements were most often found in the automotive industry”adds Magdalena Kubiak.

The technology allows today to cover plastic elements with metal. To put it simply, most chrome-colored elements inside cars, which imitate metal, are actually made of plastic and have undergone a process of applying a chrome layer that makes the part look like metal. The advantage of using plastic parts is their resistance to rust and reducing the weight of the entire car. This, in turn, has a measurable impact on the vehicle’s performance such as speed, fuel consumption, tires and other components, and of course the price. The purchase of a plastic metallization machine has been ZEM’s largest investment in recent years so far. The costly project is burdened with a normal 10 percent. deficiency caused by the impossibility of improving the manufactured products, which are additionally characterized by high sensitivity to all kinds of dirt. “It is hardest to keep clean in the spring and summer months, when there is a lot of pollen and pollutants in the air. Then we have to intensify our work to keep the 70 plating baths clean, in which the nearly three-hour metallization process is carried out, ”explains Michał Banaszewski, manager of the electroplating plant.

A technology aimed at shine

Few, looking at shiny elements in a car, realize that the metallization of plastic elements is such a complicated process. The basic problem that appears in the initial phase of implementation is the design of a hanger to attach the details before introducing them into the process. “Every detail has a dedicated tool – a tag on which it is introduced into the process. The pendant must be adjusted to the detail so that it conducts electricity properly, the details are placed not too close to each other, but as close as possible to maximize efficiency”adds Michał Banaszewski. A mistake can also be made when creating a program for a given type of detail. It is necessary to properly select the residence time of the details in the electroplating bath and the currents that are to affect the detail during the coating. “All these errors can be eliminated through the experience gained and the educated and experienced technological and laboratory staff, which we are lucky to have. The technician, which is equipment for measuring and correcting the process, which is more and more advanced, precise and faster and faster, also comes to the rescue”- explains the manager of the electroplating plant.

Before metallization, the surface should be well prepared by degreasing and etching it, so that the subsequent layers of metals have something to stick to. Then a layer of copper, nickel and chrome is applied. The process based on the innovative ZEM patent differs from the classic ones by the lack of the use of chemical nickel. This allows you to shorten the process time and increase efficiency.

Additionally, ZEM can use micro-fracture and / or semi-gloss nickel technology, if these are the customer’s requirements. The technology of this process is relatively new and some improvements are constantly being added. The plant also uses new chemicals to accelerate and improve the quality of services. “Customers usually know very well what coating they need. They often use standards in which it is precisely described what type of coating and in what thickness is to be applied to the detail. It is also important to define what tests the client requires (we at ZEM have the possibility to carry out thickness tests on an X-ray based instrument, measure layers on a couloscopy, etc.) and what thicknesses of individual layers are required (usually described in the standard). It is also important to train the staff in the field of visual inspection of details after the process and guidelines in this matter provided by the client”- says Michał Banaszewski.

Export is a priority

The priority market for ZEM is the foreign market. Currently 80 percent. sales are exported. As noted by Magdalena Kubiak, it is in Western markets that consumers buy ergonomic desks and chairs tailored to the user’s needs. The company from Duszniki-Zdrój wins the fight against foreign competition (West Europe, USA, Japan) thanks to lower operating costs and relatively low costs of purchasing components, while the Asian market (China, India) – with higher quality, reliability, as well as costs and transport time. “Many of our contractors tried to use components from Chinese companies, but most of them returned very quickly because they know that ZEM offers high quality and reliability” – says Magdalena Kubiak. He adds that so far there is a low demand for ZEM products on the Polish market. The reason is the lack of customers and low interest in this type of products. However, the company looks to the future with confidence and hopes that the domestic market will develop thanks to the younger generation, which more and more often appears in the global industry with their ideas, for example the Polish supercar, scientific projects of the Wrocław University of Technology, with which ZEM cooperates. “We hope that our contacts with Polish companies will develop and that we will be able to build the Polish economy together” says Andrzej Banaszewski.

Ambitious plans

ZEM aims high. Ultimately, the plant wants to be the most recognizable manufacturer of engines in the entire Europe for the automotive, furniture, medical equipment and other markets. It intends to be a mobile plant that takes up new technical challenges and meets the applicable European quality, environmental and legal standards. “We want to be a company that employs a staff that is satisfied and managed according to European standards and constantly improves its qualifications. A company that is friendly to the environment and the local community, and cares for the natural environment in which it exists and operates, ”says the president of the management board. The directions of development are the strategic goals of the company, i.e. market diversification, further increasing the product offer by implementing the ISO TS 16949 system and increasing supplies for the automotive industry, increasing the automation of processes by purchasing new devices and machines, eliminating ineffective processes and technologies, strengthening the company’s image as a stable employer, customer, supplier and business partner. The development plan mainly concerns the provision of electroplating services within the metallization of plastics.

Currently, the company is trying to modernize the 44X type drive mechanisms and replace them with 4XX mechanisms, which are more modern and more efficient. In addition, it focuses on the development of a galvanic line for ABS metallization. “We are constantly learning something new in this matter, but also using experience, we minimize the number of gaps and increase efficiency” says Krzysztof Mikrut. A significant challenge for ZEM is also environmental protection, and thus – reducing the amount of emitted pollutants, which are closely related to the manufacturing and production process. The plant wants to increase the effectiveness of the neutralizer and reduce the amount of water used to provide galvanic services.

The company constantly strives to improve the current assortment. The plant’s nearest plans even include the production of brushless motors, because it is in the automotive segment that ZEM sees the greatest development opportunities. “We are thinking together with current and potential customers about the possibilities of making new constructions. We are thinking more and more often about entering the market of brushless motors production, but it is a completely different product than the one currently produced, so we are trying to find a contractor who would help us gain experience and transfer know-how by installing our motors in ZEM”- notes the director of technology and development. The growing demand for brushless motors around the world is clearly visible when you see the growth of other companies in the automotive industry. One of them is the Nidec Motors plant in Niepołomice, about which we also write in the current issue.

Awards and certificates

The company has the certificates of the integrated quality management system 9001 and the environment 14001, and in the near future it is preparing for certification in accordance with the ISO / TS 16949 standard. It also won the “European Medal” for the implementation of the production of a linear actuator – type 500 – and black passivation galvanization. Every year, it also receives business credibility certificates (Dun & Bradstreet and Bisnode), as well as Creditreform credibility certificates. Andrzej Banaszewski emphasizes that despite many certificates, the greatest distinctions for ZEM are primarily a stable position on the market, cooperation with long-term contractors, dedicated and satisfied employees as well as their experience and skills.