Genrikh Altshuller’s theory, like most theories, is idealized. Its tools and algorithms work great, as they say, “in theory”. What about practice? Can it work outside the training room, where knowledge flows from one wise head to a number of other aspiring wise heads? Can it work in real cases and help to achieve results that at least meet the expectations of researchers.

In this part of the article, based on the example of the US market, I will try to prove that in fact TRIZ (its modern version) works perfectly in the process of creating innovation, especially among companies that are leaders in their markets.

However, before I turn to the evidence for the above thesis, I will present a little more history. It will be a continuation of the story started in the first part. We ended up with the fact that in the early 1990s, Valery Tsurikov went to the USA and founded Invention Machine Corporation there. The aim of its activity was to continue work on software that uses semantic search. At the same time however, there was a training line in the company (one of people responsible for it, among others, was Sergei Ikovenko, employed as the third real employee of Invention Machine) and a consulting line dealing with the real use of TRIZ tools and Invention Machine software to support companies in the process of R&D works and implementation of innovative projects. At that time, the software had already implemented three TRIZ tools: a contradiction matrix, a database of scientific effects, and standard inventive principles. However, it was just enough to provide customers with added value.

However, the beginning of the 90s was not the best moment to start such an undertaking like a consulting company with innovative of dealing with R&D works. The American economy showed signs of recession. Investors were not particularly inclined to spend money, and potential corporate clients, even if interested, often had their hands tied for the extra costs. An example is General Motors from where Tsurikov received a letter in which GM claimed that they would like to buy the Invention Machine software, but the management decided to freeze funds to buy the software for at least a year.

Tsurikov and his small team were saved from a very likely bankruptcy by the Pittsburg fair, where the company managed to attract the attention of the multidisciplinary engineering company AlliedSignal (today it is part of the Honeywell concern). A small contract signed at that time allowed the life of the Invention Machine to be extended. Another breakthrough came in 1994, when they managed to sign an agreement with Digital Equipment Corporation (DEC). The software delivery and 5-day training course earned Tsurikov about $ 20,000 in revenues (an impressive result after two years of almost no money). Today it can be said that this contract outweighed the scales. Since then, Invention Machine Corporation has grown almost exponentially. Investors started to appear – the first one was an American investor from the village of Glebokie in the Vitebsk Oblast in Belarus. Soon after, there was another – a vice president of one of the largest Canadian mutual funds, which invested $ 3 million. In turn, Intel Capital provided the company with $ 5 million and invited its representatives to a seminar organized at the US Congress in Washington.

At that time, the list of clients also began to grow rapidly – one of the first was Procter&Gamble, which signed a contract for the implementation of a whole range of innovative services worth a total of $ 400,000. Why such a willingness to cooperate between a cosmetic giant and an inconspicuous start-up from the former USSR? Perhaps because Procter&Gamble engineers were able to find a potential solution to their problem with just a few clicks when they first encountered Invention Machine. The system suggested the use of ultrasound in the process of solidifying the liquid soap. Ultimately, the time for thickening the soap was reduced from 8 hours to 3 minutes per batch, which even for the most experienced P&G employees was astonishing.

Development works were also carried out for companies such as: Xerox, Intel, NASA, Boeing, Sony and Samsung. The automotive sector needed a bit more time to find out about the profits from TRIZ solutions. However, about seven years after its inception, contracts were signed with companies such as Ferrari, Harley-Davidson and BMW. Work was also done for the Japanese Honda, where, as part of the creative work, a new cooling system for the interior of the vehicle was developed without additional energy consumption, but only with the help of a thermo-acoustic effect (engine noise was converted into a drop in temperature). The engineers from Honda told their colleagues – Boeing engineers about this effect. Soon after, the American aviation company purchased the entire series of Invention Machine software. NASA also used software in its spacecraft design to search for signals from space. The R&D team was also able to help original industries such as the cosmetics industry – for Chanel, an original packaging concept was developed for a new line of lipsticks

In 1997 Invention Machine Corporation already employed around 200 people. About 100 were software developers working every day in Minsk, and about 50 were a team of TRIZ specialists working in St. Petersburg, carrying out research and development and innovation projects. It was the latter team that was separated from the mother company in 1997 (it was done for the sake of security and business optimization) to a separate economic entity – this is how Pragmatic Vision International was founded.

1998 was another success – Spaceport Magazine[1] readers named Invention Machine the most innovative product in America. A year later, Fortune magazine named Valery Tsurikov “Hero of US Manufacturing”.

To sum up, the end of the 1990s was a success story for Invention Machine Corporation and Pragmatic Vision International. Almost every technology company on the Fortune 500 list at the time benefited from their services. In turn, after four financing rounds in which participated, inter alia, Citigroup, Dassault Systèmes, Intel Capital and Motorola, the company have raised a total of $ 35 million. However soon after that a significant changes took place – in 2001, founder of the Invention Machine Corporation – Valery Tsurikov left the company. Invention Machine Corp. itself focused more and more on the development of a specific branch of software – the semantic searched ones, while those team members who were more associated with TRIZ moved to the R&D advisory line, i.e. to Pragmatic Vision International. Professor Ikovenko was also there. I’ll give the floor to professor in a moment. But before that happens we must close this part of the story and mention how Pragmatic Vision International turned into GEN3 Partners.

The team of Pragmatic Vision International in the first decade of the twenty-first century developed and operated very dynamically. A total of about 15 people worked in the USA and they were still supported by a team of the best TRIZ specialists from St. Peresburg. The economic crisis of the 90s effectively distracted potential investors from software companies, but the unconventional scope of services (R&D consulting, development of innovations, solving production problems) and a rich and impressive portfolio of clients, attracted investors to Pragmatic Vision. One of them was James Sims (best known for the creation and success of Cambridge Technology Partners), supported by Michael Treacy (professor of management at Sloan School of Management at Massachusetts Institute of Technology) and by Arthur Toscanini (chief financial officer at Cambridge Technology Partners).

The aforementioned three founded the company GEN3 Partners at the end of the 90s[3]. It was originally intended to be a software company, but during the crisis, the founders’ concept had changed. Ultimately, the development money was used to acquire Pragmatic Vision International. In this way, the entire team and projects came under the name GEN3 Partners.

The distinguishing feature of GEN3 Partners was its multidisciplinary and ability to work with companies from almost any sector. Its then Executive Director Sam Kogan once said: “The strength of GEN3 is its ability to operate in all industries – we literally work from potato chips to computer chips[4]”. GEN3 clients list includes: Boston Scientific Corp., General Mills Inc., Chiquita Brands International Inc. or Alcoa Inc. The company had operated so smoothly that it launched a $ 50 million venture capital fund in 2005 with the goal of developing early-stage companies abroad, especially in Russia and Israel.

Of course, over the years, GEN3 Partners has changed. Part of the team left to create their own companies and projects. They created companies such as Gen5 Group, Gen TRIZ or even the DFP-Institute (founded by Sergei Ikovenko). As a chronicler, I will only mention that also Invention Machine Corporation eventually changed its owner. In 2012, it was acquired by IHS Markit for $ 40 million. However, this does not change the fact that innovative projects implemented at that time by these teams still arouse interest and amazement (especially with how it was possible to develop some brilliant innovations, especially in industries with which TRIZ specialists did not have earlier contact).

So let’s finish the historical thread, and let’s move on to the examples. Using the possibility of a direct conversation with professor Sergei Ikovenko, I asked him about examples of projects that show most clearly how the TRIZ tools, used in practice, contributed to the creation of innovation.

Here are a few of them:

1.➡ A dozen or so years ago, General Electric struggled with one of its very simple products – a switch. It was a product that had been on the market for many years, but the level of its complexity meant that the unit cost of production was too high, especially when compared to competitors’ newer products.

The aim was therefore to make changes to the switch that will reduce its production costs. Trimming and the principle of transition to another dimension were used. In this way, it was possible to design a switch which case consists of two identical elements (only one part is effectively pressed in form). One of the elements rotates by 180 and connects to the other, creating a tight case for the electronics inside. These actions allowed to reduce unit costs by up to 40%.

GE switch prototype / Source: Sergei Ikovenko training materials from GEN3 Partners Partners

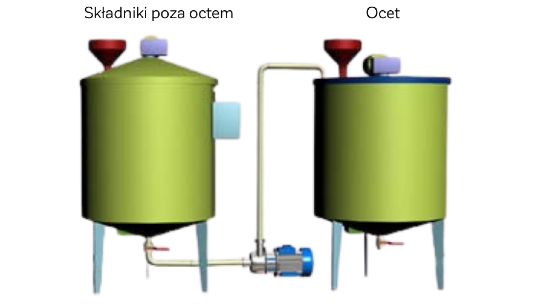

2. ➡ Kraft Heinz realized at one point that their mayonnaise production process was relatively extensive. All because vinegar (which is one of the main ingredients) must be added to the mixture in a separate tank and only after the remaining ingredients (olive oil and egg yolks) have been pre-mixed. All because added too early reacted with the yolk and disturbed the emulsification process. This, of course, increased the costs and slowed down the process itself. Kraft Heinz needed help to simplify the process.

The team of advisers, after a detailed analysis of the process, developed a concept that involves introducing all ingredients into the tank at the same time. However, in order for the reaction not to be disturbed, the vinegar had to be inactive for some time. This was achieved … by freezing it before adding it and letting it thaw already in the mixture. The advisers were led to this solution by the “Inventive Principles” tool, namely the principle of physico-chemical changes. In this way, this simple concept became a breakthrough in the production process.

Ingredients adding in the mayonnaise production process / Source: Sergei Ikovenko training materials from GEN3 Partners PartnersPartners

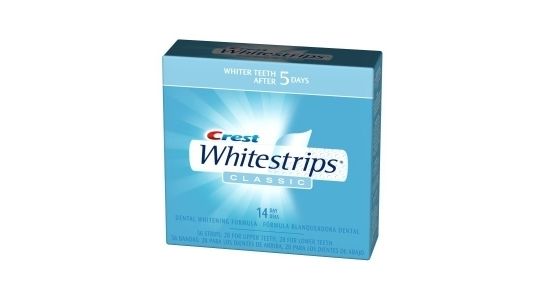

3. ➡ Procter & Gamble was one of the pioneers of home teeth whitening technology. They were the first to introduce whitening kits that consisted of a rubber mouthpiece and a small ultraviolet lamp that activated a gel containing hydrogen peroxide (which had a whitening effect). The problem, however, was that the concentration of hydrogen peroxide in the gel could not be too high, so as not to damage the sensitive soft tissues in the mouth. Low concentration, in turn, made it necessary to use ultraviolet light as an additional activator and also forced to frequent repetition of the process to achieve a satisfactory effect. In summary, despite the high interest of consumers, the product was too complex and discouraged its use.

The company could not afford to lose such a market, so it engaged a team of TRIZ advisors to work on changing this concept. And the change was radical – the concept was taken from the nicotine patches that were becoming popular at the time. For if you can precisely release nicotine from the patch into the skin and deeper into the body, why not release hydrogen peroxide from the patch precisely on the tooth enamel … this is how “WhiteStrips” was created – a product that revolutionized the market and displaced all alternative solutions from it. Unofficial sources indicate that the product brought P&G over USD 100 million in profit in the first year of its presence on the market.

Source: Sergei Ikovenko training materials from GEN3 Partners

4.➡ Intel is another example of a big company with a problem. During the production of processors (extremely precise and sterile), a layer of photoresist (photosensitive emulsion) was applied to the silicon base. The essence of this stage of the process was the proper spinning of the substance so that it formed a perfectly even and smooth layer. The problem that arose was the unwanted air bubbles that could become entangled in the sticky substance when it was applied to the silicon wafer. Such a bubble drove a groove in the photoresist during spinning. As you might guess, this meant removing the layer and repeating the process.

The team of advisers involved in the work claimed that it was not possible that no one had ever faced a similar problem. That there must be a solution somewhere which could be adapted. In order to reach such a solution, it was decided to look for a technology not so much related to the problem of a bubble that destroys a layer of substances – they went deeper, to the causes that affect gas precipitation in liquids, and this is where the search began. The solution was found in an industry that a processor manufacturer would probably turn to last – with sparkling wine producers. This is where the right moment of the bubble formation is a matter of life and death (for a bottle of champagne of course). The key turned out to be the valve ensuring laminar flow of the liquid. After appropriate adaptations, a similar solution was implemented at Intel.

Damage in the photoresist layer / Source: Sergei Ikovenko training materials from GEN3 Partners

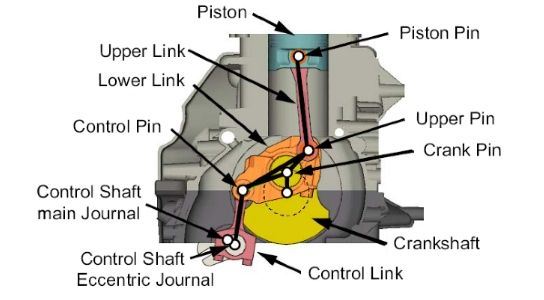

5.➡ Another example is the problem of the Hyundai Motor Group, which realized that to remain competitive, it needed a variable-compression engine in its range. As such, the solution is known quite well, but at the same time perfectly protected by the then leader – the Nissan group.

Hyundai representatives set themselves the goal of developing a solution that would take the best elements from the competition, but at the same time would not infringe upon Nissan’s intellectual property rights. A team of advisers was engaged to help, which began by modeling the Nissan solution.

The part of the engine responsible for the possibility of changing the pressure in the cylinder has been written down to the smallest element, in particular focusing on those fragments indicated in the patent as independent and dependent claims. Then, using i.a. trimming they managed to simplify the solution so much that it was possible to patent it by Hyundai. In the next step, two more versions of this solution were created and patented – not with the intention of implementing them into production, but so that they could not be implemented in production (due to the existing protection) by the competition[6].

Diagram of a piston operation in a Nissan engine / Source: Sergei Ikovenko training materials from GEN3 Partners

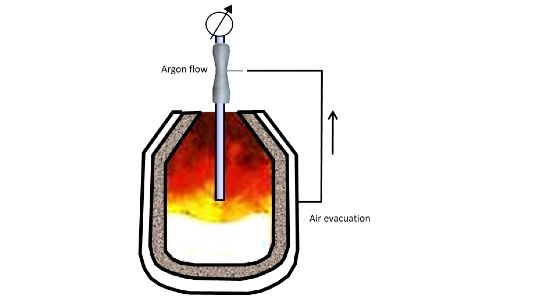

6.➡ Another example also comes from South Korea. The Posco company (a Korean and global giant in steel production) identified a problem during the cleaning process of pig iron. In order for the final product to have the desired properties, substances that precipitate impurities are added to the pig iron. However, precipitation alone is not enough. They still had to be removed from the crucible. A pressurized argon stream was used for this. The gas disrupted the contents of the crucible, leading to the deposition of impurities on the porous walls. At the same time, however, the blown argon and porous walls effectively cooled the material inside (which, of course, was undesirable). To prevent this, the crucible was additionally heated, which in turn increased the production costs. As part of the work on the problem, a patent of the defunct Mannesmann company was found. It assumed the creation of an additional layered cover on the crucible and the use of a pump that sucked the gas from between the layers to prevent the formation of thermal bridges and heat leakage (it was something similar to the operation of a thermos).

Posco considered buying a key patent, but in the end it turned out to be too expensive and it was decided to develop its own version of this solution. TRIZ methodology tools quickly identified an additional compressor, which is loud, expensive and unreliable, as one that should be removed from the Mannesmann technical system. However, the key challenge remained – how to force the air to escape from between the layers covering the crucible. Since one of the elements of the system was a pressurized argon injection system – which gave argon momentum, and therefore meant that there was energy that could be used – the base of scientific effects in this area was verified. This pointed to a Venturi tube – a device that causes a drop in static pressure in the pipeline (generated by argon flowing under high pressure). The local pressure drop was just what the Posco engineers needed. The Venturi tube was connected to the crucible cover air extraction system, and the rest was done by physics. What’s more – the phenomenon of air suction could not be patented, but the specially developed Venturi tube definitely could.

Source: Sergei Ikovenko training materials from GEN3 Partners

Professor Ikovenko’s team also contributed to a number of other innovations. Among other things, a car wiper has been developed which, when it goes backwards, does not draw water back onto the glass, or a method of producing baby diapers, in which no needles but jets of particles are used to puncture the absorbent layers (a solution directly from the space sector). Honda was supported in the development of a fuel tank integrated into the scooter frame and Chiquita Brands International (the popular banana company) has developed an innovative way to store the fruit so that it ripens exactly when it hits store shelves

As you can see, the TRIZ methodology is not only a collection of theoretical insights, idealized tools that cannot be used in the real world. TRIZ is real solutions and innovations that have been able to shake up many markets.

At the end of this part, I would like to anticipate one question that may arise after reading the above examples – is this methodology suitable only for the world’s largest companies and concerns? Now I will only answer that with one word – no. It can also be used by small (family), medium or even large companies, but operating on the scale of a single country. What’s more, even classic startups will find several tools that will help them develop.

![How do leaders create innovations in a systemic way? [PART 2] How theory turns into practice How do leaders create innovations in a systemic way? [PART 2] How theory turns into practice](https://industryinsider.eu/wp-content/uploads/innowacja-980x512.jpg)