The COVID-19 pandemic, despite having erupted more than two years ago, is considered by the WHO (World Health Organization) as a continuing health threat that affects populations around the world.

This pandemic, being primarily a humanitarian crisis, has entailed equally serious social and economic implications. The actions of central banks did not save us from the coronavirus and are unlikely to save us from new infectious disease epidemics either, as monetary policy is completely powerless against the accompanying supply and demand shocks. The International Monetary Fund predicts that the current crisis will cost the world economy $12.5 trillion by 2024.

In addition to the comprehensive efforts of the pharmaceutical industry, can advanced materials engineering help us straighten out this twisted reality of a sanitary regime, lockdowns and anxiety about the future? All signs point to yes.

Two weeks ago, on July 5, the final gala of the 24th Edition of the Polish Product of the Future Competition was held at the Ufficio Primo, a gem of Polish postwar architecture, in Warsaw, where the award in the “Joint Product of Higher Education and Science Institutions and Entrepreneur” category went to the innovative technology of bioactive nanocomposite particles, which was developed by Agnieszka Maria Jastrzebska – PhD, and subsequently implemented by ADJ Nanotechnology, a spin-off special-purpose company, in its own manufacturing practice.

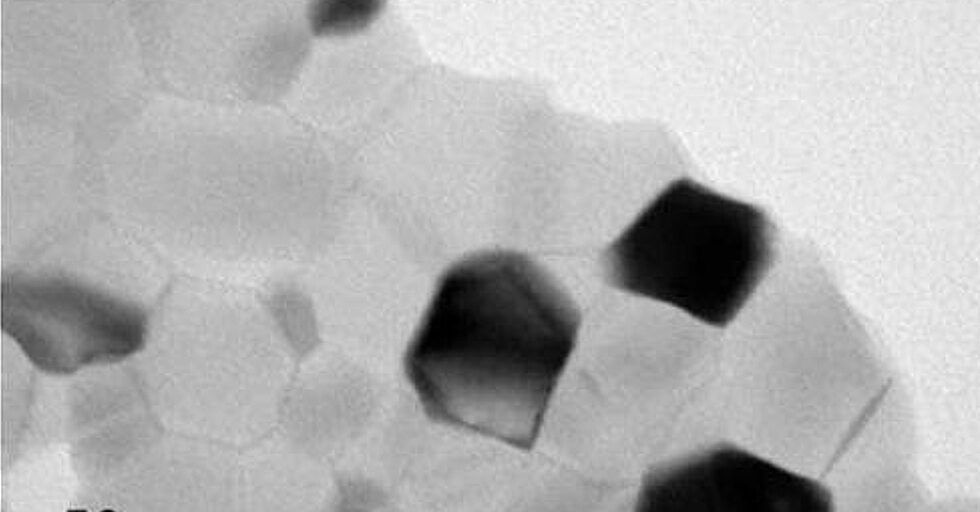

It is a unique deep-tech technological solution, based on nanostructure engineering, which consists in arbitrary combination of different types of nanocomponents (ceramic, metallic) in a permanent nanocomposite system. Such particles can be called a 2-in-1 product, as they combine both nanosilver and nanocopper held together by a ceramic matrix in a single structure.

A permanent bond between the nanocomponents is formed during a process based on simultaneously occurring chemical reactions. Thus, the bioactive nanoparticles do not separate from the ceramic stabilizing matrix. There is no more emission of free nanoparticles into the environment. The developed solution is also environmentally friendly, produced using non-toxic organic metal salts by “green chemistry” techniques. It also does not generate process waste.

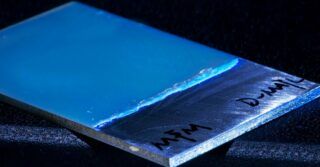

Due to the unique bioactive properties of the nanocomposite particles and their stability in varnishes, self-sterilizing protective coatings were chosen as a target industrial application. The R&D results were first applied in the printing industry for coating paper and textile products, and then as an additive to plastic coatings.

Such coatings can be used in health care facilities, retail, entertainment, educational facilities, restaurants and movie theaters where large numbers of people gather, posing an epidemiological risk. As an example, we can mention the tourism and hospitality industry, characterized by high exposure dynamics. – Prof. Jastrzebska explains.

As a result of obtaining a stable nanocomposite system, unique bioactive properties are obtained, i.e. favorable nullification of cytotoxic and ecotoxicological properties while maintaining high biocidal efficacy, based on the ionic mechanism, at a significant cost reduction. The particles are also stable and safe, not releasing the harmful nano fraction. Given the growing demand for health-safe products, constantly fueled by information about the increasing number of illnesses and even deaths caused by bacteria that are increasingly resistant to antibiotics, traditional products on which large amounts of bacteria accumulate have become unattractive and unresponsive to the needs and expectations of informed end users.

The performance characteristics of ADJ nanocomposite particles have radically changed previous approaches to nanotechnology and the development of self-sterilizing coatings. Unlike other solutions available on the market, nanocomposite particles can be added to materials of various types, where they retain their activity and enhance user safety. Unlike impermanent and harmful silver and copper systems based on free nanoparticles or formed by simply mixing them, ADJ’s innovative nanocomposite particles have antimicrobial activity only in ionic form. Thus, they are not only safe for the environment, but work just as effectively as an additive to a variety of materials, giving them self-sterilizing properties.

The sol-gel technology used by the start-up in its own production allows the company great flexibility in the selection of raw materials for synthesis, while the process itself can be described as a so-called one-pot, where individual reaction substrates are added to the reaction mixture. This makes it possible to obtain nanopowders with unique chemical composition and properties. Other bulk raw materials can also be introduced into the reaction mixture, which are then coated with nanoparticles with a composition corresponding to the substrates in the mixture. In this way, a hybrid nanostructure is created, the chemical composition and parameters of which can be easily tailored to the detailed requirements of the end user.

The resulting nanoproducts can be called “tailor-made”, having unique functional features. In doing so, they are limited only by the imagination of the creators of the nanostructure, the need to provide specific functionalities and, of course, cost.

Thus, the process of manufacturing nanomaterials is characterized by high innovation. This is supported by a simple concept, flexibility of production and a virtually unlimited combination of possible chemical compositions of the manufactured nanoproducts.

“The nanomaterials developed by Prof. Agnieszka Jastrzębska can find application not only as protective coatings in general. They can be used wherever water and wastewater treatment is needed, in air filtration and anti-smog protection, as a means of extending the life and durability of construction materials, for the elimination of animal odors and for industrial catalysts, performing all necessary functions.” – Tomasz Konecki, Head of Business Development in ADJ Nanotechnology, adds.

The author of the patent, Agnieszka Maria Jastrzebska, Ph.D., in addition to being a professor at the Warsaw University of Technology and the founder of ADJ Nanotechnology (also serving as its CEO), is also the author and co-author of 12 other patents in the field of nanotechnology and more than 90 scientific publications, cited nearly 1,500 times, which allows her to be among the world’s leading scientists in the field of materials engineering.