After only two years of existence, NGL Machining is at the forefront of companies providing services in the field of on-site machining. It carries out the largest projects in the industry in Poland and many ambitious projects abroad. The rapid development and success of the company were determined by investments in the machinery park, successively extending the scope of services and possibilities.

Experience gained in the shipyard

The company was founded by specialists from the shipbuilding industry who successfully use the knowledge and experience gained in construction and repair of ships in the field of mobile processing. Knowledge of the principles of operation, the existing dependencies and operating parameters of individual ship devices allows them to develop and apply the appropriate implementation and repair methodology. It is especially important during regeneration works carried out on devices and machines included in the ship’s engine room. The company operates not only in the maritime and shipbuilding industry, but also in the energy, chemical and petrochemical, metallurgical and mining industries as well as offshore.

The company was established in 2015, at a time when orders from Polish and foreign shipyards accounted for approximately 80% of the company’s total sales. The situation changed dramatically at the beginning of 2016, when the maritime industry was hit by a deep crisis caused by the fall in oil prices in the world. In order to stay in the market, NGL Machining focused on other industries: chemistry and energy. This resulted, among others, in participating in the repair work carried out for Grupa Lotos during the SPRING 2017 Repair Shutdown. For three weeks, a team of 15 people, having 10 different machines at their disposal, performed over 100 regenerations of flange connections. It was the largest project of this type in Poland for years.

NGL Machining works well wherever machining is difficult and requires non-standard solutions. Currently, he works in the construction and maintenance of energy, chemical and food plants, as well as in the construction of steel structures and ships. It carries out various, sometimes very unusual projects, the implementation of which until recently was impossible or was a real logistical and economic challenge.

“The possibilities offered by on-site machining today are practically unlimited. The combination of technology with the skills and experience of operators and measurement teams allows us to implement even the most complex projects, ”says Rafał Bogusz, co-owner of NGL Machining.

Unconventional projects every day

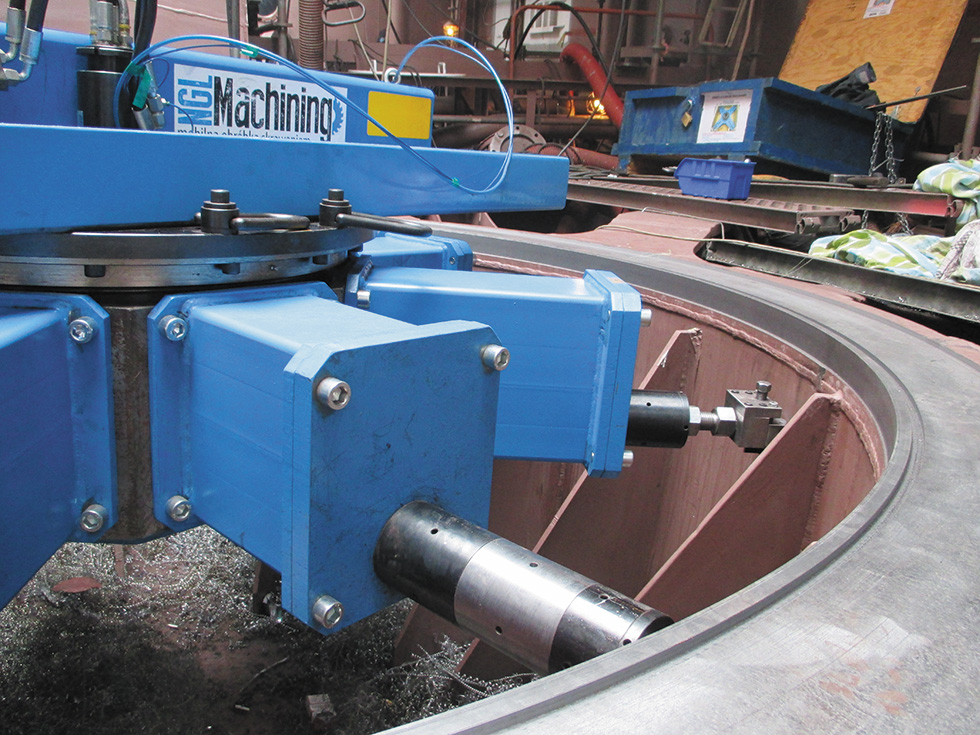

Each of the over one hundred projects carried out annually is unusual in some respects – due to the place of work, scope of processing, access to the processed element or time of completion. Such non-standard projects of the company include the treatment of the seating unit and foundation surfaces on the Zourite self-elevating barge, carried out by the CRIST SA Shipyard. The barge construction project used 100% of the possibilities of mobile processing. For 40 days, the 20-person executive team worked on 15 different portable machines in two shifts: flange lathes, milling machines and boring machines. He processed 160 seats with a diameter of up to 300 mm, 16 foundation surfaces with dimensions of 160 × 840 mm and 4 foundations for azimuthal thrusters with a diameter of up to 2140 mm. The barge turned out to be not only the largest in terms of its parameters (the largest crane installed on a ship with a lifting capacity of 4.8 t), but also the largest project in the field of mobile processing carried out in Poland in 2015. The difficulty resulted mainly from the time when this task was had to be done. Due to the shipyard’s production conditions, it was reduced from 70 to 40 days. “It was almost unrealistic to make this project, but we managed to do it,” says Rafał Bogusz. – The operators, working day and night, rose to the occasion. They did their best, once again proving their great value to the company. ”

Another example going beyond the standard implementation was the project of regeneration treatment of seats for labyrinth seals on steam turbines carried out in Egypt, at one of the local power plants. In this project, the atmosphere for this type of activity turned out to be the greatest challenge. Egypt, considered to be one of the richest and most developed countries in Africa, in practice turned out to be a country completely unprepared for cooperation with a foreign service company. The work itself took only 14 days, but the logistics in general took over six months. The formalities that had to be dealt with so that NGL Machining could get the equipment to the place of work stood in the way. It is worth mentioning that the machines were stuck in a customs warehouse in Egypt for weeks. After long negotiations with the Egyptian bureaucracy, the company regained them and transported them to the place of work.

“Despite all the adversities, both sides were satisfied with the results,” says Rafał Bogusz. – The sense of our satisfaction with this project is great, because we are aware that we have made it in a remote corner of the world, where the client, somehow doomed to a foreign company, could invite the largest global services to cooperate with them, which, due to their human and hardware resources, could give greater guarantees as for the timely performance of the service. However, he decided on us, which was a great honor. We are glad that we were able to help him, and our work contributed to the commissioning of the power plant, thanks to which production in the nearby industrial plants was able to start again ”.

In order for such demanding projects to be implemented, NGL Machining invests in the team and continues to expand it, assuming that the employees constitute the greatest value of the company. A team of experienced turners and millers is often on a business trip 12 hours a day. Their work is service-oriented, which means that they are always ready to provide services.

Modern technologies

Executive precision in a company with such a specialized activity requires the use of the most modern, most accurate machines and measuring instruments. When carrying out works in the field of mobile machining, NGL Machining uses specialized portable machines, designed with limited spaces in mind. Mobile boring machines, milling machines and lathes are characterized by a compact and modular design that allows them to be mounted in virtually any space. It is equipment that has been adapted to work in harsh conditions using a propulsion system that allows to provide optimal power in relation to the proportion of gravity.

On-site machining as an alternative to stationary machining focuses on the performance of the service while eliminating the need to disassemble and transport the workpiece. As mobile and stationary machining are two different manufacturing technologies, they are used in the implementation of various scopes of work. These technologies are rarely used interchangeably. What can be done conventionally on stationary machines is not done on portable machines and vice versa. Technical and technological solutions as part of mobile processing are used in those industries where both the dimensions of structural elements and their availability are a problem in the renovation and production technology. The elimination of transport costs with the simultaneous development of the service service allows for much faster implementation of production tasks, and in the event of a failure – faster restoration of production continuity.

The very process of machining with the use of mobile cutting machines is similar to machining in the case of stationary machines. It consists in the precise removal of material surpluses while maintaining the execution tolerance regime. The most important difference is that portable machines are delivered to where they need to be used and are mounted on the component that needs to be machined, not the other way around. The individual stages of work, regardless of the type of machining performed, are usually repeatable stages: transport, control measurements, assembly and setting of the cutting machine, actual machining, disassembly, measurements after machining, transport. The process, in which logistics takes up up to 60%, seems very complex and time-consuming, but not in the case of mobile processing. “The savings offered by mobile machining cannot be overestimated. Each time, by resigning from transporting a workpiece, we save a lot of time and money ”- emphasizes Rafał Bogusz.

Depending on the type of processing, specificity and conditions prevailing in a given plant, NGL Machining develops and then implements an executive methodology, ensuring its implementation in the shortest possible time, with the least number of logistic operations. From a technical point of view, the machining process itself is a repetitive process, carried out on the basis of generally accepted principles used by tool operators. There are no major differences in this respect depending on the type of plant in which the work is carried out. Slight differences may concern the type and method of preparation and assembly of cutting machines as well as on-site logistics. Working differently in a shipyard in production than in chemical plants when carrying out regenerative treatment. Each of the plants has its own work culture, requirements and regulations to which NGL Machining adjusts each time.

We are competition

“Our biggest advantage is ourselves. It may sound arrogant, but it is undoubtedly one of our greatest assets – says Rafał Bogusz. – Although we have become a leader in our industry on the Polish market, we have not rested on our laurels. Me and my partner are actively involved in projects all the time, often working physically, hand in hand with our employees. Thanks to this, we do not lose touch with the market and we manage to maintain extremely close relationships with customers. Nothing inspires respect more than a job that we are not afraid of.

The founder of NGL Machining adds that this approach to running a business has its downside, but at the moment this model of running a business works and brings success.

The key values that have made it possible to achieve the success so far are the quality of services and equipment, as well as the experience of the people employed and the working conditions created by the company. According to the founders of the company, this allows them to stand out from the competition. The highest quality is to attract to NGL Machining not only clients, but also all entities from the business environment.

Strategy and investments

The strategy adopted by the company for 2015–2020 assumes development by expanding the range of services provided. It is related to the expansion of the owned machine park and human resources. The company plans to increase the share of services in the field of mobile machining on the European market. Currently, around 20% of projects are carried out outside Poland. By 2020, the company wants to increase this share to approximately 50%, while strengthening its position on the domestic market.

The demand for services in the field of mobile machining in Poland is still growing. The industry is relatively young, it only started operating a few years ago. A lot has changed during this time: the awareness of market participants about the opportunities offered by mobile machining has increased, access to specialized machines has expanded, new service companies have been established, including NGL Machining. “Although we are still lagging behind Europe and the world in terms of the number of projects that appear in Poland, Poland is at the international forefront in terms of execution capabilities. This is evidenced by the orders we receive. For example, the one we undertook recently, in Singapore, where the shipowner, having numerous local companies at his disposal, decided to download our service, bearing exceptionally high transport costs, ”says Rafał Bogusz.

He adds that in the next few years, projects much more technically advanced than is currently the case will start flowing into Poland. Companies such as NGL Machining must be well prepared for their implementation. The biggest challenge right now is the ability to predict what problems will be faced and the appropriate adjustment to this machine park. There is a high probability that in the near future the projects will require the construction of special machines with oversize dimensions. Companies that focus on building such solutions are already winning in the industry.

NGL Machining received a subsidy under the Regional Operational Program of the Pomeranian Voivodeship for 2014–2020. The purchasing plan for the next three years includes a number of machines that complement the existing machinery park as well as machines and devices that allow to extend the scope of services provided. Particularly advantageous in this respect can be the purchase of the largest of the mass-produced boring machines and a flange lathe. These are devices that allow the processing of internal diameters of embeds up to 2000 mm and contact surfaces of foundations up to 8000 mm. The purchase plans also include a laser tracker that performs real-time control measurements, thanks to which the machining process will be further optimized.

![By 2030, the market size of metal processing tools is expected to reach $120.44 billion [REPORT] By 2030, the market size of metal processing tools is expected to reach $120.44 billion [REPORT]](https://industryinsider.eu/wp-content/uploads/xcutting-tools-320x167.jpg.pagespeed.ic.SgnEk-RWA-.jpg)