We talk with Ewa Kruchelska, the CEO of CRIST SA, about why European shipowners choose CRIST SA shipyard, development opportunities in the offshore market, and the self-elevating barge called Zourite, nicknamed the “octopus.”

CRIST SA shipyard has been operating in the shipbuilding industry for 25 years. During this time, it has built a reputation both in Poland and abroad, and this is certainly not an easy industry. How did you manage to specialize in specific areas within it?

The shipbuilding industry is demanding, but we never wanted to simply drift on the turbulent waters of this market. From the beginning, we knew we were capable of more. Over the course of 25 years, we’ve shown that we can practically make anything out of steel, and our clients know it. Specializing in specific areas is important, but what sets us apart from other companies is our openness and courage. We simply enjoy challenges.

We undertake projects for both the land and maritime industries. We mainly focus on building prototype and technologically advanced structures, as demonstrated by this year’s Zourite project – a self-elevating barge known as the “octopus.” It is a unit that works successfully in the construction of a prestigious road on the French island of Reunion. Currently, we are working on an environmentally friendly passenger and car ferry for a Finnish shipowner. This vessel, designed for harsh conditions, will operate using hybrid propulsion powered by a combination of batteries and/or generators.

At the same time, we have ventured into the offshore market quite boldly. By building ships for wind farm installations, we have demonstrated our technological and human potential.

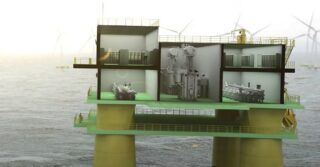

We also successfully fulfill orders for steel and hydrotechnical structures, such as wind farm foundations, steel components for substations, locks, caissons, and turbines.

The company is trying its hand in various areas, but as a company, you must have set some priorities. In which direction do you plan to go in the coming years?

The market is constantly changing, so we need to be flexible. We observe the situation and try to respond appropriately. We have high hopes for the offshore market, even though the number of proposals from this segment has decreased after the downturn in oil prices. Last year, only 6% of our quotation requests were related to offshore units. Nevertheless, we are convinced that in the longer term, demand for larger units of this type will rise again. Based on expert opinions and the inquiries we receive, we estimate an interest in the offshore industry, but not before 2020. We are eagerly awaiting that moment. Today, we have the opportunity to gain new experiences, and we want to make the most of it.

We want to fill the gap in orders in the offshore industry by building passenger and passenger-car ferries, including electric ones. Nearly one-third of potential orders concern units of this type. However, this does not change the fact that priorities evolve with the market, which is fluid. Our task is to meet customer requirements, so we strive to raise standards, including obtaining additional quality certifications, which are essential in today’s world.

So, are you primarily focusing on shipbuilding?

We are open to various types of orders. Last year, we classified almost half of the proposals submitted to us as “other.” These included floating docks, pontoons, substations, and steel membranes, among others. Our production capabilities allow us to carry out hydrotechnical structures and products used in land construction as well. These are also important market segments that we take very seriously.

At the same time, an important part of our company’s activities is the construction of complex units for the construction and operation of offshore wind farms. We have produced ships for servicing wind farms (OSV, AHTS, Multi-Purpose). We also participate in technical dialogue during the construction of wind turbine components. Regarding wind farms, it’s worth remembering that the wind energy obtained must be converted into electrical energy, for which offshore substations are needed. We are currently engaged in advanced pre-contract discussions for the construction of such structures.”

CRIST SA is primarily known for shipbuilding and steel construction. Which of the previous units can be considered flagship for the shipyard?

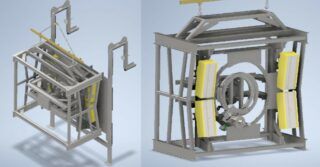

Certainly, the Heavy Lift Jack Up ships stand out as self-elevating floating cranes. They are characterized by their specialized “legs” (jack-ups) that set themselves on the seabed and allow the ship to be raised above the water level. The jack-ups we have in our portfolio typically have four “legs” and were used for the installation of offshore wind farms. An exception is the previously mentioned Zourite, which required as many as eight “legs” for the construction of a viaduct. These types of ships are also equipped with cranes with very high lifting capacity (4,400 tons in the case of Zourite).

In the context of shipbuilding, due to the customized nature of our projects, we cannot strictly classify the types of vessels we produce. The units are tailored to the customer’s needs, and we do not have a narrow specialization in terms of the types of vessels built. Among the technologically complex units we have produced, we can mention three service vessels for a Norwegian shipowner. Their role is to operate around seismic vessels and control other approaching objects to avoid disrupting ongoing research. We have also produced units with highly advanced systems for the transport and distribution of feed on salmon farms.

In addition to small specialized units, we also manufacture fishing vessels, typically with lengths of 30–40 meters. Thanks to our own dry dock, which is 380 meters long, we have a wide range of production capabilities, even for large vessels. Our largest units to date include Heavy Lift Jack Up ships such as Innovation (length 147.5 meters, width 42 meters), Vidar (currently Vole au Vent, length 140.40 meters, width 41 meters), and Zourite (length 107 meters, width 44 meters). One of the largest vessels built by CRIST SA is the cable laying ship Ceona, delivered in 2014, with a length of 199.4 meters and a width of over 32 meters.

As you can see, the shipyard is not short of orders. How many projects do you work on in one year?

We work on 15-20 different projects simultaneously. The workload depends on the type and complexity of the construction. Fully equipped units or those subject to stricter regulations require more time. Over the past 25 years, we have completed over 300 projects of varying technological complexity for our clients.

I would like to emphasize that each project is a new experience. Technology is advancing at an incredibly fast pace, which means that each new order presents interesting challenges. An example of this is Innovation, which was named “Unit of the Year 2012” in a global review of technical units. Another unusual project was Zourite, which received media attention not only nationally but also internationally.

However, this is not the last interesting project this year…

After Zourite, the most important project for us is a ferry with the working name P310 double-ended. It will be a modern vessel with hybrid propulsion powered by a battery set and/or generators. The unit will serve as a road ferry connection between the Finnish towns of Parainen and Nauvo. The ship is designed to transport 90 passenger cars and 372 passengers and will have a crew of three. It will be equipped with a battery set with a minimum lifespan of 10 years, which will be automatically charged during loading and unloading (in approximately 7 minutes).

We don’t want to reveal too much about future projects at this time. Currently, we are negotiating more than 30 orders, including ferries, caissons, fishing vessels, and wind turbine tower foundations.

From the company’s perspective, is the market situation good?

The past few months have shown that the global market situation can be described as challenging. After the drop in oil prices, shipowners reduced their activity in the area of new builds. There are relatively few projects, and when one does emerge, more shipyards compete for the order than before. However, it cannot be said that the shipbuilding industry is doing poorly; quite the opposite. Currently, we are producing several structures and participating in lengthy negotiations. We are still receiving inquiries as well. Last year, we managed to sign contracts for 10% of all submitted offers, which is a very good result in the shipbuilding industry. In the near future, we expect increased interest in passenger ferries, units with high ice class, such as patrol vessels, and fishing vessels.

What are the advantages of the company then? Why do European shipowners trust CRIST SA?

In the shipbuilding business, technology and production capabilities are crucial. They are what allow us to first secure contracts and then build high-quality vessels. This is why CRIST SA shipyard is preferred over Romanian, Turkish, or Croatian shipyards. Another equally important aspect is timeliness and relatively short lead times.

Looking from a different perspective: innovation, experience, and technology serve as an invitation to collaboration. We strive to meet our customers’ requirements to the best of our abilities. In all of this, we cannot forget our employees, who are excellent specialists. The nature of working in such a challenging industry demands a high level of dedication from them. Often, this translates into long hours at work, stressful situations, and a constant race against time. So, the company’s success is built not only on the right decisions. The strength of the company lies in its people – regardless of their roles, they share a passion and a commitment to timeliness. And, of course, technology, which gives us an edge over the competition.

What sets CRIST SA apart in terms of technology?

Compared to European standards, we have significant lifting capacity. Our gantry crane with a lifting capacity of up to 1,000 tons is one of the largest on the Baltic Sea coast. It allows us to move blocks into the dock, significantly reducing the production cycle. But that’s not all. We have an automated initial profile processing line and water plasma cutting for steel. Water effectively suppresses dust, and filters purify the water from harmful metal oxides. Plasma cutting is faster than standard methods due to the absence of the need for preheating the material. Additionally, thanks to high cutting speeds, temperature has little impact on the material’s properties. It’s also worth mentioning that this is an eco-friendly solution.

At the same time, by launching production in the former Gdynia Shipyard areas, we have the ability to undertake large projects. The dry dock, 380 meters in length (one of the largest in Europe), is of particular importance to the plant’s operation. Currently, in Gdynia, we produce units of a different type than a few years ago under the previous owner. We divided the dock into three parts, making it possible to simultaneously assemble blocks of a larger number of units. With the support of the European Union, we also implemented a project to build a wind tower production plant on the shipyard’s production grounds in Gdynia, within which a complete line for the production of large-diameter pipes was launched.

As you can see, the company has large technological capabilities. What are your goals in the field of production?

I consider our main goal to be continuous improvement and the execution of successive projects in accordance with the set objectives, customer expectations, and maintaining the highest quality standards. We also plan for further investments in infrastructure, renovations, and the replacement of the most worn-out machinery.

This strategy allows not only to maintain high quality production, but also on an individual approach to each client?

Certainly. An important element of fulfilling consecutive contracts by the shipyard is the ability to tailor units to the specific needs of individual customers. We approach each project individually. Each time, we need to prepare documentation for the given project. Based on it, we verify and examine the structural details. If any uncertainties arise, we discuss them with the customer. We strive to adapt the unit to their requirements and our production capabilities. We engage in a dialogue with the client, aiming to understand their needs as best as possible, while also recommending construction strategies that allow for project completion on time. An ideal example is a crab fishing vessel. It’s a narrow vessel characterized by an exceptionally shallow draft. It works well in small water areas specific to the Netherlands. We adjusted its parameters to fit within a narrow canal specially designed for aquaculture needs.

The technological process in the shipyard is a flexible factor and is constantly being improved. That’s why, among other things, we collaborate with the academic community. Together with universities, we commission specialized research, offer internships or practical training for students, and participate in conferences organized by scientific research communities. Our collaboration with Gdańsk University of Technology and the Eugeniusz Kwiatkowski Technical Schools is particularly noteworthy.

We also cooperate with engineers from StoGda, the Center for Ship Technology (and many others), who significantly support our activities in areas such as model testing and design. A company that wants to thrive must surround itself with specialists.