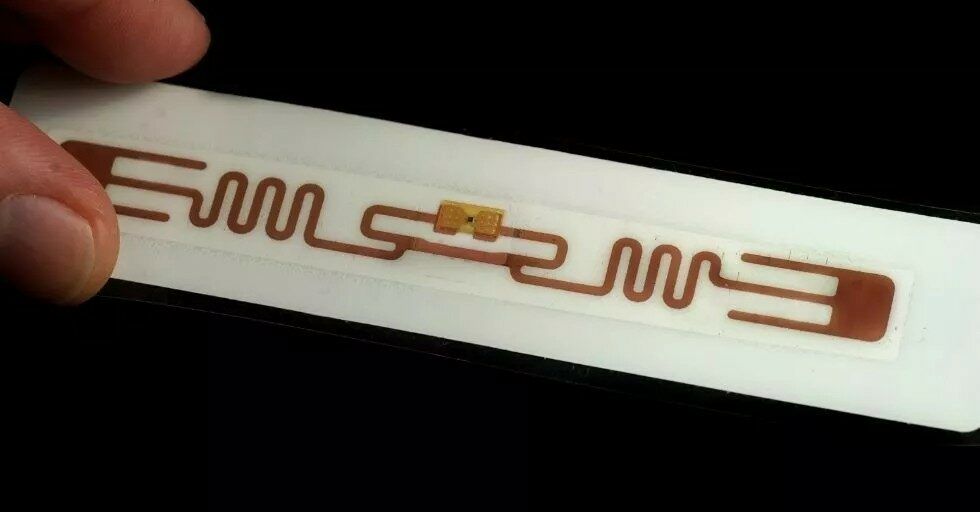

RFID labels are becoming increasingly popular in industry, thanks to their unique identification and tracking capabilities. RFID (Radio Frequency Identification) technology allows wireless data transfer between a label and a reading device.

As well as being more durable and outlasting barcodes, RFID tags allow users to automate logistics, track products in real time and improve production processes. With Industry 4.0, RFID is becoming increasingly important to underpin automation and IoT (Internet of Things) solutions.

In this article, we will focus on the history of RFID label technology and its various industry applications. We will also examine the challenges associated with RFID labels and their role in Industry 4.0.

The history of RFID labels

RFID labels were first developed in the 1930s, but it was not until microprocessors and other electronic technologies emerged that industry really started using and leveraging their capabilities. Initially, they were mainly deployed for military and space applications, but their use gradually expanded to other industries such as logistics, food industry and automotive as RFID technology developed and became more cost-effective. Over time, this saw the technology play a key role in automating production processes, managing resources and even facilitating security.

Currently, RFID labels are used in many different industries including logistics, automotive, F&B, pharmaceutical and chemicals, as well as healthcare, retail and agriculture.

The use of RFID labels in industry:

- To automate logistics

- To track products in real time

- To identify objects and improve production processes

RFID tags in manufacturing have wide-ranging and versatile applications. They can improve production processes, which helps streamline operations and cut costs. They allow product expiration data to be tracked in real time, for more effective resource management and quality control. RFID labels also pave the way to identify objects more swiftly and easily, so that industry safety is enhanced and various processes can be automated.

The technology is used in industry to track vehicles and machinery. Companies wanting to manage their fleets or plan routes more effectively can automatically track vehicle and machinery location and status for smoother and cheaper transportation.

RFID tags can also be used to identify and track containers and packaging automatically, for more effective warehouse management and automation of logistics processes.

For all the above reasons, RFID labels have become a key industry tool, facilitating efforts to automate and enhance workflows. RFID helps companies track products and vehicles and work more efficiently, economically and safely than ever.

Challenges associated with RFID labels

The use of this solution in industry also comes with certain challenges: cost above all. RFID labels and reading equipment can be prohibitively expensive for some companies. The costs associated with implementing and maintaining RFID systems are also similarly high.

Another important challenge is data security. Without proper protection, the technology may allow unauthorised data access. This underlines the need for companies to use appropriate security measures like data encryption to mitigate such risks.

Regulatory compliance is another issue. RFID labels may be subject to personal data protection and information security regulations. Companies must be aware of them and adapt their RFID systems accordingly to avoid financial penalties or reputational damage.

In conclusion, despite numerous benefits, companies must note the challenges associated with using RFID, such as costs, data security and regulatory compliance. It is important that companies take appropriate measures to tackle these challenges and optimally exploit RFID’s potential.

The role of RFID labels in Industry 4.0

RFID labels play an important role in the Industry 4.0 concept, which encompasses automation, communication and data analysis.

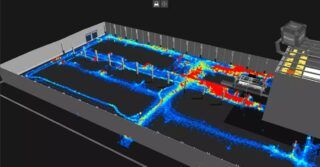

Automation is the first key element of Industry 4.0. RFID labels allow logistics processes to be automated and products and machinery to be tracked, to streamline operations and cut costs. RFID tags also allow products to be automatically identified and tracked, which improves warehouse management and allows automation of logistics processes.

Communication is the second key element of Industry 4.0. RFID labels improve the flow of communication between products, machinery and systems, which, in turn, allows the processes and data flow to be managed more effectively.

Data analysis is the third key element of Industry 4.0. RFID labels allow data on products and vehicles to be tracked automatically, for better resource management and more effective planning. Data obtained from RFID labels can also be analysed, for better decision-making and improved production processes.

Summary

Ultimately, despite the challenges associated with using RFID tags, such as cost, data security and regulatory compliance, this technology allows for automation, communication and data analysis, which go a long way to manage processes more effectively and improve workflows. In short, companies can be run more efficiently and economically.

They offer an effective solution to Industry 4.0 implementations with similar gains. With RFID tags, logistics processes can be automated and products tracked, letting users keep a handle on all warehouse variables. This is particularly crucial in the current era of intensifying competition.

It is also worth reiterating how these tags allow products and vehicles to be automatically identified and tracked, for optimal resource management and planning. They underpin more effective business decisions and make companies more efficient and competitive.

RFID Solutions Provider – SATO

SATO is one of the leading RFID label providers in the market. The company portfolio includes wide-ranging products, from RFID label printers to self-adhesive labels and dye tapes, known for their high quality, reliability and ease of use. Leveraging unique solutions like high-speed printers and advanced data management options, SATO helps its customers increase efficiency and reduce costs.

SATO also offers support in implementing RFID labels and solving issues related to their use. It solves industry issues across the board, helping its customers work more effectively, cut costs and manage processes effectively.