It’s surprising how often companies reach a ceiling when it comes to their production efficiency. Finding the right balance between optimizing repetition and finding new ways to increase output is a difficult but necessary task. Unfortunately, many businesses remain stuck at a certain level of production efficiency, unaware of the potential benefits that come with exploring new methods.

The root of this issue often lies in the beliefs and mindsets of the people in charge. Here are three of the most common limiting beliefs that prevent companies from reaching a higher level of production efficiency.

I Don’t See a Reason to Change

Some managers and production drirectors fail to recognize the importance of innovation when it comes to production. As long as their current system is working, they don’t bother exploring new methods or technologies. This is a major mistake, as it prevents them from unlocking higher levels of efficiency that could propel their business to the next level.

Adopting new technologies and methods can open up new opportunities for companies. It can improve their workflow, reduce waste, and ultimately increase their bottom line. Sticking to the same methods and technologies will only lead to stagnation.

Innovation is crucial for companies to remain competitive and relevant in today’s fast-paced business environment. It allows companies to stay ahead of their competition by developing new products and services, streamlining processes, and improving the customer experience. Failure to innovate can result in lost market share, decreased profits, and ultimately, the failure of the business.

One of the biggest reasons why some managers and production directors resist change is the fear of the unknown. They are comfortable with their current systems and processes and are hesitant to try anything new. However, this mindset can be detrimental to the company’s success. It’s important to remember that new technologies and methods have been developed to address existing problems and improve efficiency.

To embrace innovation, managers and production directors should keep up-to-date with the latest industry trends and advancements. They should attend conferences, read industry publications, and network with other professionals in their field. By doing so, they can identify opportunities for improvement and explore new methods and technologies that can help them achieve their goals.

Another way to encourage innovation is to foster a culture of creativity and risk-taking within the organization. Employees should feel empowered to share their ideas and take calculated risks to drive innovation. Encouraging experimentation and learning from failure can lead to breakthrough ideas and new processes that improve efficiency and productivity.

I Can’t Afford It

The cost of implementing new technologies or methods can be intimidating, especially for smaller businesses. While this is understandable, it’s important to remember that the costs associated with these changes can be mitigated.

For starters, it’s important to research the options before committing to any specific technology or method. Companies can often find more cost-effective solutions if they take the time to look. Additionally, there are often government grants or subsidies available to offset the costs of implementing new efficiencies.

Another way to reduce the costs of implementing new technologies or methods is to consider outsourcing certain tasks or projects to third-party service providers. Outsourcing can often be more cost-effective than hiring in-house staff and investing in the necessary infrastructure and training.

Another option is to gradually implement changes rather than all at once. This approach allows businesses to spread out the costs over time and can make the transition smoother for employees and customers.

Finally, it’s important to remember that the cost of not implementing new technologies or methods can be even greater in the long run. Outdated processes and technologies can lead to inefficiencies, lost productivity, and decreased customer satisfaction, which can ultimately impact the bottom line. By investing in the right changes now, businesses can position themselves for long-term success and growth.

Paper Reports and Excel is Enough for Us

Many companies are comfortable with the processes that they currently have in place, relying on paper reports and Excel spreadsheets to track their production. However, these methods can be incredibly labor-intensive and error-prone.

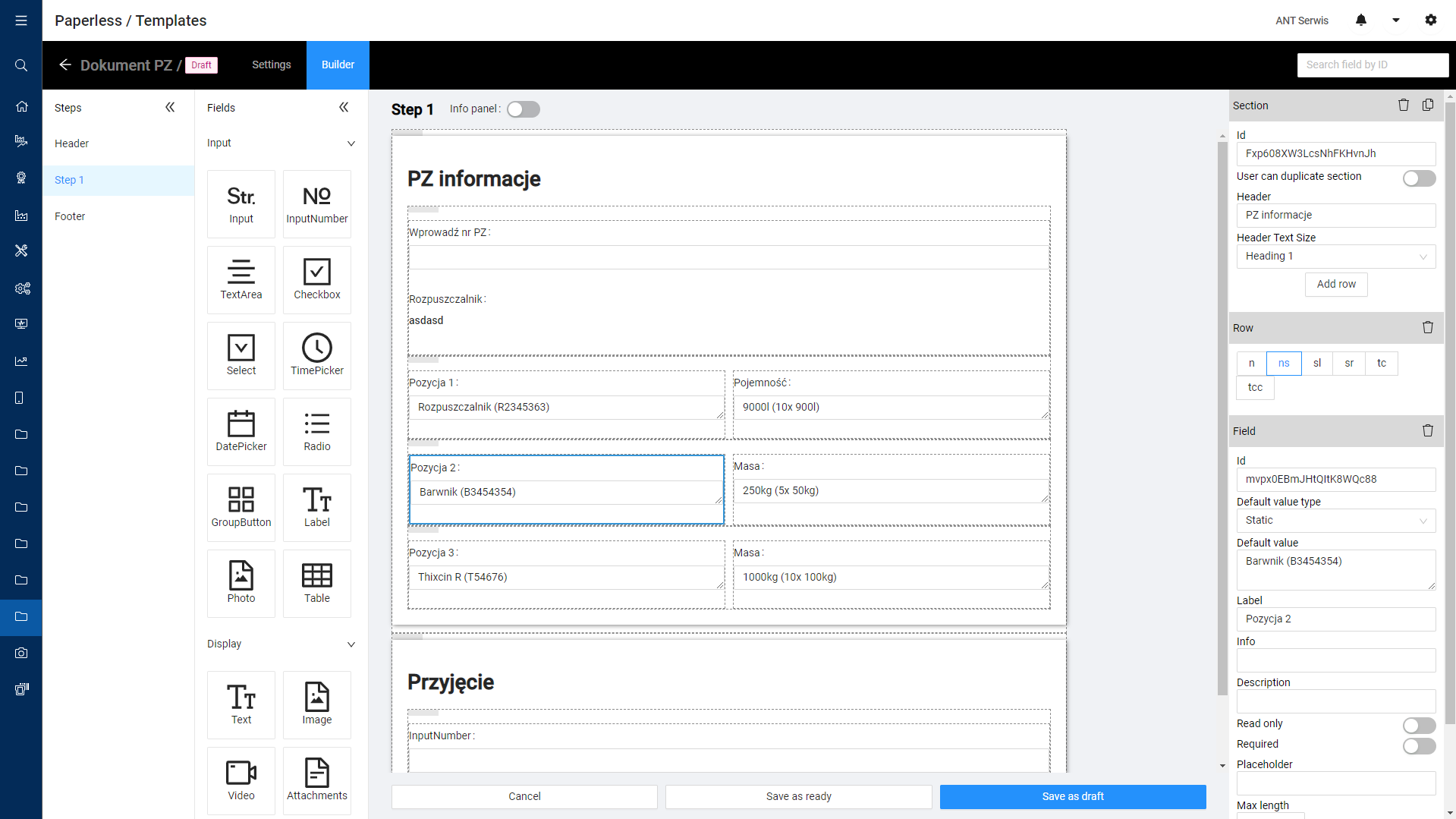

These outdated approaches can be replaced with modern cloud-based solutions that are easier to manage, require fewer resources, and produce more accurate results. Implementing these types of solutions can drastically improve a company’s production efficiency, leading to a better bottom line. A good example of this is paperless software, which allows the paper-based exchange of forms to be completely transformed into a digital workflow.

The takeaways from this article should be clear; There are many common beliefs that limit production efficiency, and companies should strive to break out of these limiting mindsets in order to achieve higher levels of efficiency. New technologies and methods can open up new opportunities and ultimately lead to better profits, but they need to be researched carefully in order to get the best deals. Additionally, outdated processes like paper reports and Excel spreadsheets should be replaced with modern cloud-based solutions that are easier to manage and produce more accurate results. By taking the time to explore new methods and technologies, companies can unlock higher levels of production efficiency that can bring great benefits to their businesses.

Efficient operation through investment in production software

It’s clear that companies should look for ways to improve their production efficiency to achieve better profits. One way to do this is by investing in a Manufacturing Execution System (MES). MES solutions are designed to streamline the production process and make it more efficient. They can help manage production data, automate processes, and provide real-time visibility into the production environment. They can also reduce errors and waste, improve process tracking and quality, and even increase the speed of production.

By investing in a MES solution, companies can drastically improve their production efficiency and unlock additional competitive advantages. It also allows them to make more informed decisions, as they can have access to real-time data that paints a clear picture of their production processes. Companies should also be sure to find a MES provider that offers reliable support and up-to-date technology to ensure that their solutions remain effective and up-to-date. With the right MES solution, companies can optimize their production process, improve efficiency, and boost profits.

Find out more about Systems for Manufacturing at: https://antsolutions.eu/