Automatic bottling and conveyor systems in beverage and liquid food production set high requirements for energy efficiency, operational reliability, wash-down-capability and corrosion protection. As one of the world’s leading full-range suppliers for mechanical and electronic drive technology, NORD DRIVESYSTEMS knows the industry’s requirements and provides efficient, hygienic and reliable solutions for bottling and conveyor technology in beverage lines.

Easy to clean, energy-saving operation, high precision positioning, low operating costs: Drive systems used in automatic bottling systems for the beverage industry must reconcile various requirements – just NORD DRIVESYSTEMS’ area of expertise. The family company from North Germany is the global leader in drive technology and provides customised drive solutions with high energy efficiency, user-friendly plug & play technology, smooth surfaces and long service life.

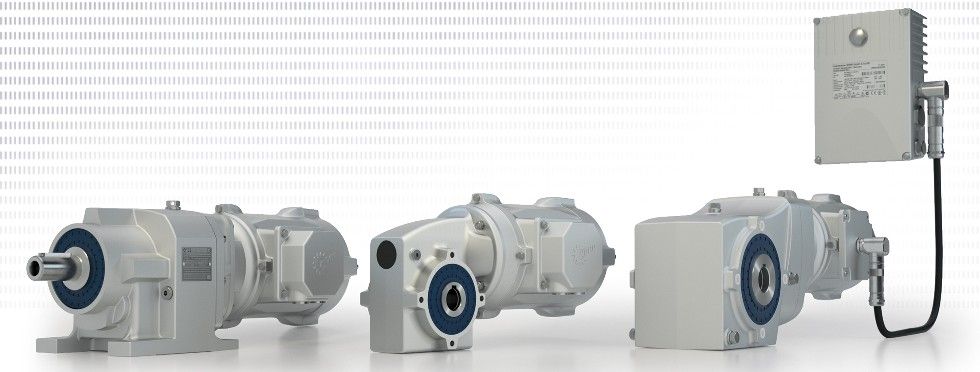

DuoDrive geared motor: High energy efficiency, low operating costs

The innovative and patented DuoDrive geared motor integrates a high-efficiency IE5+ synchronous motor into the housing of a single-stage helical gear unit, and with a system efficiency of up to 92% achieves one of the highest efficiencies on the market in this power class. Very high system efficiency is also achieved in the partial load range. The constant motor torque over a wide speed range allows for consistent version reduction and reduction of operating costs. Together with the simple plug-and-play commissioning, this results in a significant reduction in the Total Cost of Ownership (TCO) in comparison with existing drive systems. The unventilated, wash-down design with smooth surfaces meets the most stringent hygiene requirements and ensures optimum cleaning.

NORDAC ON/ON+ is a compact and Intelligent frequency inverter for decentralised use / Image: NORD DRIVESYSTEMS

NORDAC ON/ON+: Decentralised frequency inverter with integrated Ethernet interface

Beverage bottling is an area where the demand for decentralised drive technology is on the rise. NORD offers an optimal solution with the smart NORDAC ON/ON+ frequency inverter. NORDAC ON/ON+ covers power ranges up to 2.2 kW and is characterised by an integrated Ethernet interface (ProfiNET, EtherNET IP and EtherCAT can be set per parameter), full plug-in capability and a very compact design. Decentralised inverters are ideally suited for integration into bottling and conveyor systems and thus save space as well the extensive motor cable wiring required for centralised frequency inverters.

The nsd tupH surface treatment provides an outstanding anti-corrosion treatment for drive components in wash-down-optimised cast aluminium housings for the beverage industry / Image: NORD DRIVESYSTEMS

nsd tupH surface treatment: An alternative to stainless steel

The nsd tupH surface treatment is available for DuoDrive as well as for NORDAC ON/ON+. Thanks to a special method, the surface is made corrosion-resistant and harder and makes aluminium behave like stainless steel with regard to corrosion protection. This is not a coating, but a surface treatment that creates a protective layer which is permanently bonded to the substrate material. So nothing can detach or flake off. The drives are easy to clean and largely resistant to acids and alkalis. It is even possible to use high-pressure cleaners or apply aggressive media. nsd tupH treatment is available for most of NORD modular drive systems made from aluminium.