Why Use a Gearbox or Reducer?

Torque Magnification

The most common reason for needing a gearbox of any kind is for increasing the torque generated by a motor. Planetary and Cycloidal reducers provide mechanical advantage by decreasing speed and increasing output torque.

Inertia Matching

Servomotors can only control up to 10 times their own inertia, and if response time is critical, the motor should control less than four times its own inertia. When you add a gearbox to a motor, the inertia that the motor sees is divided by the ratio of the gearbox squared, increasing the inertia that the motor is able to control! (application inertia ÷ 5² – if using a 5:1 gearbox)

Speed Reduction

Servomotors typically run most efficiently at speeds between 3000-4000 RPM. Cycloidal and Planetary gearboxes reduce output speed by their ratio, allowing motors to run at higher speeds than what would be possible when driving the load directly.

What is the Difference between Planetary and Cycloidal Gearboxes?

Precision and Backlash

All of Onvio’s Cycloidal and Planetary Gearboxes are considered high precision and generally designed for motion control applications, as opposed to power transmission. Within the world of high precision reducers there is still a wide range of precision levels.

Precision Defined: When discussing gearboxes/servo reducers, precision is a term referring to the amount of lost motion that can be expected in repeated movements. The goal being to perform the same action(s), while maintaining best possible positional accuracy.

Backlash is generally considered the best indicator for the precision level of a gearbox. Therefore the lower the backlash, the higher the precision level. Onvio’s Planetary Gearboxes range from 3-15 arc minutes of backlash, and the Onvio Cycloidal is the only true Zero Backlash servo reducer available in the industry.

Ratio

A single planet set can typically achieve ratios from 3:1 to 10:1. To create ratio’s above 10:1, a second stage of gearing must be added creating a dual stage reduction. Onvio’s standard planetary reducers are offered in ratios from 3:1 to 100:1. Higher ratios can be achieved by adding additional stages of gearing as needed. With each additional stage of gearing, backlash is created, decreasing the precision of the gearbox.

Onvio’s Cycloidal Reducer is offered in ratios as low as 10:1 and up to 225:1, all with a single compound reduction stage. This allows all available ratios to maintain precision as ratio increases. This is not common to all cycloidal technologies, and only Onvio’s Cycloidal Gearbox offers Zero Backlash, regardless of ratio.

Size

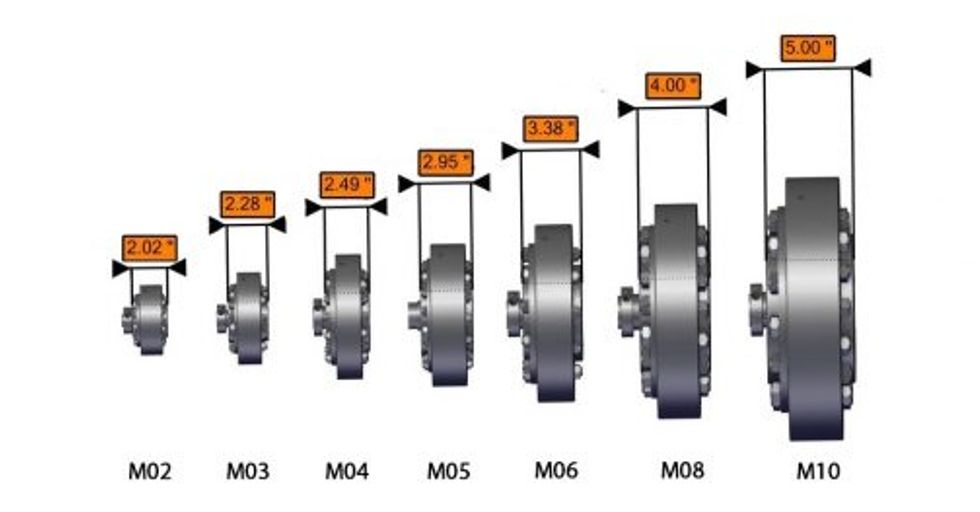

Depending on your application, the physical size of the gearbox you select can be a critical factor in deciding the type of technology required. As a general rule, planetary gearboxes will have a small diameter and longer axial length, while cycloidal will have a short axial length but large diameter. In planetary gearboxes, length can change drastically based on the number of stages and torque required. Cycloidal reducers typically grow in diameter based on the amount of torque needed, but axial length only increase incrementally.

Onvio Cycloidal Gearboxes showing Axial length / Illustration: Onvio

How to Decide Which to Use?

Understanding application requirements for backlash, ratio, and size is often enough to identify a preferred gearbox technology. Choosing the right gearbox can also require an understanding of bearing capacity, torsional stiffness, shock loads, environmental conditions, duty cycle, and life of operation.

If you are still unsure of what technology is best for your application, Contact Onvio to speak with an engineer. We can help you gather the necessary information and do the calculations to correctly spec the best gearbox for your application.