The fourth industrial revolution is gaining momentum and is already present in every industrial sector. Industry 4.0, as it is called, is characterised by the use of integrated IT systems which allow precise machinery management; easy communication between production equipment, production lines, departments and companies; as well as use of advanced data collection and analysis techniques which minimise human error in production processes. If you are interested in these topics, we invite you to participate in the conference “Manufacturing analytics“.

However, the implementation of new controllers on the machines is not enough for a plant to be called a smart factory. For this purpose, it is necessary to implement intelligent automation techniques that allow for analysis and drawing conclusions based on the collected data. These techniques are called artificial intelligence.

AI: Artificial Intelligence

What actually is artificial intelligence? It is a set of methods that allow you to analyze data and draw conclusions based on it. The common feature of these methods is the ability to learn, or improve their performance based on the data received.

Artificial intelligence is a collection of a huge number of algorithms. The most common terms you will hear of are Machine Learning, Deep Learning, and Reinforcement Learning.

Machine learning uses data to create a program that performs a learned task. The quality of the program we get depends on the quality of our data. The obstacle in implementing machine learning correctly is the huge amount of data required to teach the ML model how it should behave. Cloud technology has come to the rescue, and its development has enabled gathering and storing of gigabytes of manufacturing data. This data is a key step forward to implement artificial intelligence in manufacturing processes.

Deep learning is a subset of machine learning. These are methods that use deep neural networks (those with at least 3 hidden layers of neurons) to perform a given task. Neural networks are a black box model, you don’t know what is hidden underneath the next layers of neurons, but they are able to generalize the problem from the data received and determine a solution for it.

Reinforcement learning, like deep learning, is a type of machine learning. It is a method that gives a great deal of freedom in defining the problem. It isn’t as data hungry as other models, because it requires a definition of an agent and an environment where the agent can learn. The agent is the model that is supposed to learn to perform a certain task, while the environment describes everything that surrounds the agent. A key to reinforcement learning is the reward that the agent receives if it correctly performs the task.

How can MATLAB help?

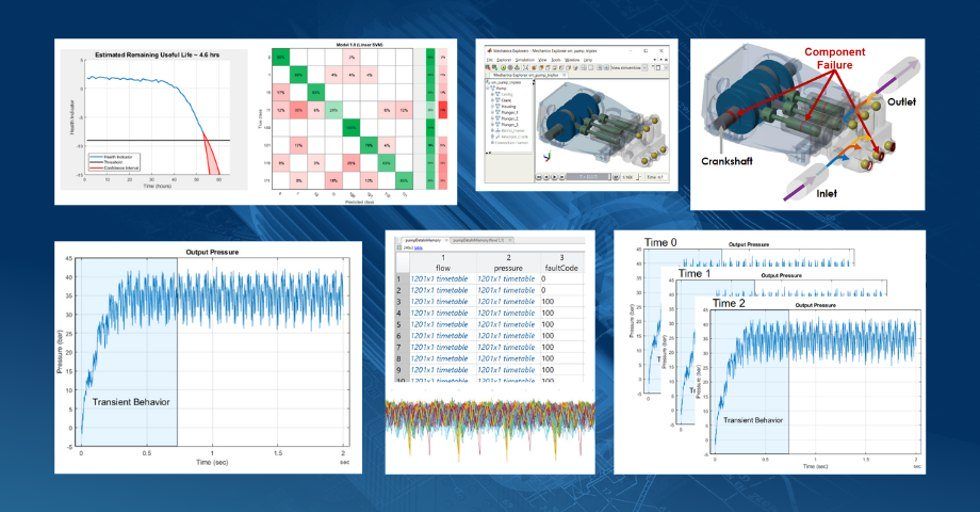

MATLAB software supports the whole process of designing and implementing artificial intelligence solutions in manufacturing plants. Such process is divided into 4 stages.

Stage 1 – Data preprocessing

Before teaching the AI model, it is necessary to perform data preprocessing. Depending on the artificial intelligence model used, these steps may vary. The data collected does not always have the right labels, is noisy, does not have the right format or size, or simply some of the data is wrong.

In MATLAB, loading and processing large amounts of data is made possible by the Datastore object, which contains a list of addresses to the corresponding data files. Key features of this object are the ability to define a number of functions to modify the collected data, the ability to load only individual data files, and a list of supported data formats such as images, text files, Excel files, or even custom file formats.

Pre-processing can also be accomplished by using integrated image/signal labeling or signal processing applications to de-noise or filter the data, remove outliers, or automatically plot frequency characteristics.

Step 2 – Model creation and learning

Lack of knowledge about artificial intelligence models and lack of skills to program such a model are common concerns before implementing AI in manufacturing processes. MATLAB has something to offer here as well such as already implemented functions allowing creation of neural networks by adding predefined layers or defining your own, extracting features from data or creating an agent model and environment. Integration with Python allows to implement neural networks created there to MATLAB and use additional options such as model analysis and model re-learning, visualization and model debugging, or even code generation from the AI model.

As I mentioned, not everyone is able to program an AI model, so MATLAB offers ready-made applications for teaching classification and regression models (categories of machine learning models), applications for graphical design and learning process of neural networks, or applications for designing and training a reinforcement learning model. This is referred to as a “low-code” or “no-code” approach, allowing you to go through the entire process writing very little code or no code at all.

Stage 3 – Model optimization

The prepared and taught model will not achieve the desired results right away. It will need to be optimized. Optimization can be done in terms of model performance, but also in terms of future implementation on target devices. The former will require careful analysis of the results, in particular incorrect predictions; improving the data set used for learning by, for example, producing more data; tuning the hyperparameters of the model.

The latter, on the other hand, is very important for deep learning, where neural networks reach gigantic sizes in terms of memory occupation. These are not ready-to-implement solutions. For this, it is necessary to perform pruning of neural network by removing layers that do not show high activation or do not significantly affect the final model predictions.

Stage 4 – Deployment to target systems

Having the artificial intelligence model ready, tested and optimized, all that remains is to deploy it on the target system. This could be a machine controller, embedded system, HMI or server. In each case, however, it is necessary to generate the code or application that will allow the AI model to be implemented on a given machine. MATLAB makes this step easy by providing functions for generating C/C++, VHDL code, and creating standalone applications. Integration with services such as Docker allows you to place applications prepared in MATLAB on the cloud or on a server.

What are the benefits of AI?

Artificial intelligence provides extensive opportunities for automation and process optimization. It is a tool that begins to surpass human abilities in data analysis and drawing accurate conclusions from the presented facts. There are companies that have taken advantage of the potential hidden in artificial intelligence techniques and implemented them in their solutions:

– Baker-Hughes implemented a predictive maintenance software based on machine learning that resulted in projected $10 million of savings.

– GSK used deep learning to create applications that allow manufacturing data to be easily analyzed, even by less experienced personnel,

– Daihatsu developed an AI model that classifies engine sounds just like an experienced mechanic,

– Lockheed-Marin saved dozens of simulation hours by implementing interpolation of results using deep learning,

– Mondi analyzed 7GB/day of collected data using machine learning resulting in significant savings of €50,000/year.

If you would like to learn more about how artificial intelligence can be used to solve problems such as defect detection in industrial machinery, process optimization, and the creation of digital twins (a digital model that replicates the real system), we invite you to the conference on these topics. “Manufacturing analytics” is a conference taking place on May 24th and 25th , where during three presentations the use of machine learning will be demonstrated along with a full workflow, as well as usage of digital twins and their creation using AI or physical modeling. In addition, the possibilities of integrating AI in an industrial environment will be presented. During the workshop taking place on the second day of the conference, participants will have the opportunity to learn how to use machine learning in the detection of machine defects, both in a traditional programming approach as well as using a “no-code” approach.