Not long ago, brick-and-mortar stores dominated the retail landscape, attracting flocks of shoppers seeking everything from apparel and cosmetics to electronics and hardware. Within this environment, distribution centres typically sorted a case just once.

However, in today’s e-commerce world defined by individual, direct-to-consumer orders, this sortation burden can multiply into more than 100 sorts. As a result, the need to sort quickly and accurately has dramatically increased market demand for automated sortation technologies.

Traditional supply chain process

The journey of products from warehouses through the supply chain and ultimately to consumers at traditional storefronts used to be a fairly straightforward process. For example:

- A retail store running low on staplers places a replenishment order with the corporate distribution centre.

- The distribution centre ships a full case of staplers to a retail store.

- Store personnel put the staplers on a shelf.

- A customer arrives at the store, walks to the appropriate aisle, and selects a stapler from the shelf.

- The customer purchases the item and departs with it.

E-commerce is changing the game

Today, the shopping process a customer used to perform at retail stores — walking the aisles, selecting items, and getting them home — now falls to the supply chain far more often. This also means a significant increase in the number of handling processes (including automated sorts) required at the distribution centre. Instead of shipping an entire case to a retail store, the distribution centre must ship single units individually to each consumer.

This new process takes place in the following steps:

- An order for a stapler (likely one of multiple brands, styles, colors and options) is received by an online retailer.

- An associate at the distribution centre picks the stapler and transfers it from the pick zone via conveyor.

- The stapler — along with hundreds of thousands of other individual picks — arrives at a sortation point, where it is transported and diverted to an order consolidation or pack-out area.

- Once packed, the ordered stapler is sorted again, this time by outbound destination.

- After leaving the facility, the order may go through several more sorts at local carrier and regional destination hubs through the last-mile carrier.

Other considerations

Further complicating the situation are the limited available labour to manually handle e-commerce’s increased order volumes, sharply increasing transportation and freight costs, and customers’ expectations for free shipping.

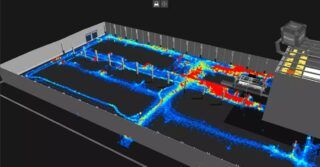

Add in the need for distribution centres to store a broader assortment of products than ever before to satisfy the expectations of customers, and it becomes evident that floor space is at a premium. Distribution centre operators must find ways to maximise the number of chutes in a fixed amount of space in order to increase order consolidation and outbound sortation potential.

The end game of sortation also changes as the smaller order quantities of e-commerce dictate a greater focus on sorting items to containers, rather than dock doors, to accommodate new sortation strategies like zone skipping.

Automation is key to staying competitive

With so much of the e-commerce customer experience depending on accurate, efficient order fulfilment and fast, free delivery, businesses must invest in distribution centre operations to keep up — while remaining both competitive and profitable. As a result, the demand for automated sortation solutions to help consolidate, separate and route the proliferation of individual orders at maximum throughput rates is booming — a trend that’s likely to continue for some time.

➡ For more information and strategies for helping your distribution centre to stay competitive with automated sortation, download Honeywell’s free sortation capacity white paper, available here.