Environmental aspects represent one of those factors which influence on decisions made by manufacturers increases continuously. And the environmentally-friendly approach is not limited solely to a product and a production process. It also determines an approach to the logistics, including packaging. Shipment of large-size and heavy goods becomes increasingly complicated and expensive, partly due to problems within supply chains, and partly due to its environmental impact.

So companies from sectors associated, among others, with the automotive, household appliances and furniture sectors or metallurgical and chemical industries have a hard nut to crack. On one hand, strong materials, such as wood or Styrofoam, are required to secure their products within the logistic chain. On the other hand, there is a great pressure on elimination of elements that have an adverse environmental impact, exerted by legislators, consumers, and manufacturers themselves, as they strive to achieve established sustainable development objectives.

On the top of this, there is an increasingly noticeable cost pressure. Rising prices of fuels and raw materials lead to drastically growing costs of transport. Within last two years, prices of shipments increased by 15% on average. Additionally, you need to consider environmental fees and costs of disposal of packaging that cannot be recycled or composted.

Designing of environmentally friendly packaging can be an answer to this problem. It assumes a development of a well-considered concept that reduced emissions of carbon dioxide throughout the supply chain and makes the packaging more environmentally friendly. This can be achieved, among others, by reducing the transport volume and the weight of material used as far as possible, while ensuring appropriate protection of packed goods. Mondi, a manufacturer of sustainable corrugated solutions, designs its large size packaging in accordance with those principles.

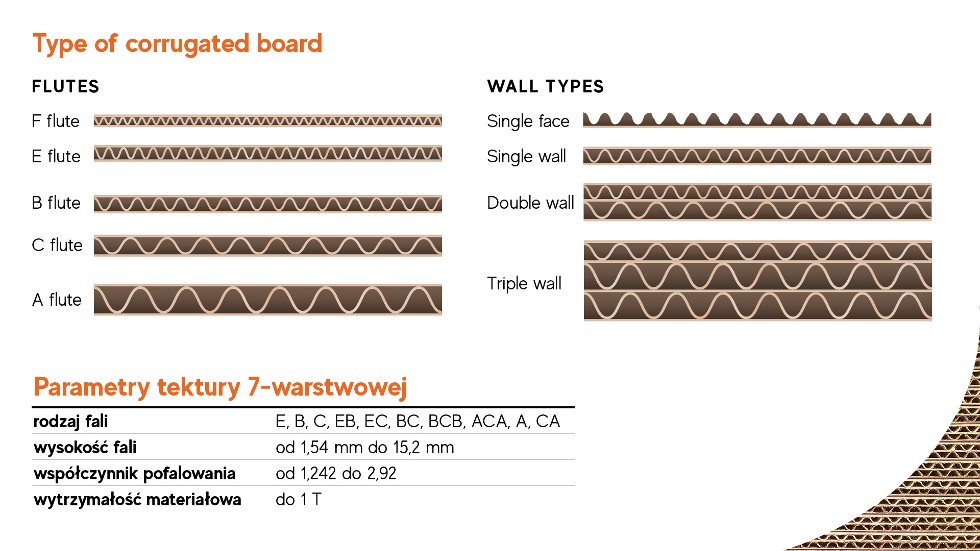

Large size cardboard packaging of the increased strength protects goods that may weight even up to one tonne. A container made of 7-layer board enables a safe transport of heavy contents even in a hot and humid climate. Furthermore, its other advantages include a possibility to tailor it precisely to product specific characteristics and transport requirements, easy servicing, and logistic capacity.

Such packaging is designed at the Mondi Simet plant in Grabonóg near Poznań. With the investments in machinery, it is one of the most modern plants in Europe manufacturing packaging solutions of this type. Investment plans assume that by 2028, the plant will reach its target volume for large-size production, i.e., 37 million square meters.

A modern corrugator, using paper of a width of up to 2.8 m, can manufacture board at a speed of 400 running meters per minute. It is equipped with various quality assurance systems. The board is processed into packaging on automated machines from renowned European producers.

Mondi closely cooperates with its customers at each stage of packaging development: from an analysis of needs, through design, up to implementation of new industrial packaging of increased strength. The optimisation of large-size packaging for transport of bulk products is an interesting example of such cooperation. Initially, the customer used octagonal cartons of the octabin type, which were transported on standard pallets. Following consultations, the packaging design was adjusted to pallet dimensions, to maintain its functionality while reducing its transport volume. The customer lowered its costs and carbon footprint by reducing a number of transports and using the available cargo space in an optimal way.

7-layer board used in large-size packaging gives more opportunities to create a designed tailored to specific needs, especially for products that are heavy or have untypical, complicated shapes. By eliminating Styrofoam and wood, companies can optimise their logistic processes, reduce costs and adjust to the requirements of sustainable development.

7-layer board used in large-size packaging gives more opportunities to create a designed tailored to specific needs, especially for products that are heavy or have untypical, complicated shapes. By eliminating Styrofoam and wood, companies can optimise their logistic processes, reduce costs and adjust to the requirements of sustainable development.

Parameters of 7-layer board

New packaging undergoes compression strength, drop, puncture resistance, and water resistance tests. For example, simulations of free fall of filled packaging on its base, edges and corners are performed. During this test, the packaging with its contents is dropped from a height representing real transport conditions. This way it can be checked whether gluing and seams can endure the impact force and the packaging correctly protects goods inside.

The implementation of such customised solutions requires a good understanding of customer needs, as well as market trends shaping them. The public discussion focusing on issues of environmental pollution shows how important the sustainable packaging manufactured in a closed circuit from renewable, environmentally friendly materials is.

Therefore, Mondi invites you to an extensive discussion on the future of packaging. It covers a series of events, including webinars and cyclic workshops in co-development, at which we check various perspectives of business practitioners, structure our knowledge, and search for new concepts meeting the business challenges.

If you want to keep your finger on a pulse of trends shaping the packaging market, read opinions of experts in this sector and learn how to prepare for approaching changes, visit the following website: https://mondinewsletter.gr8.com/

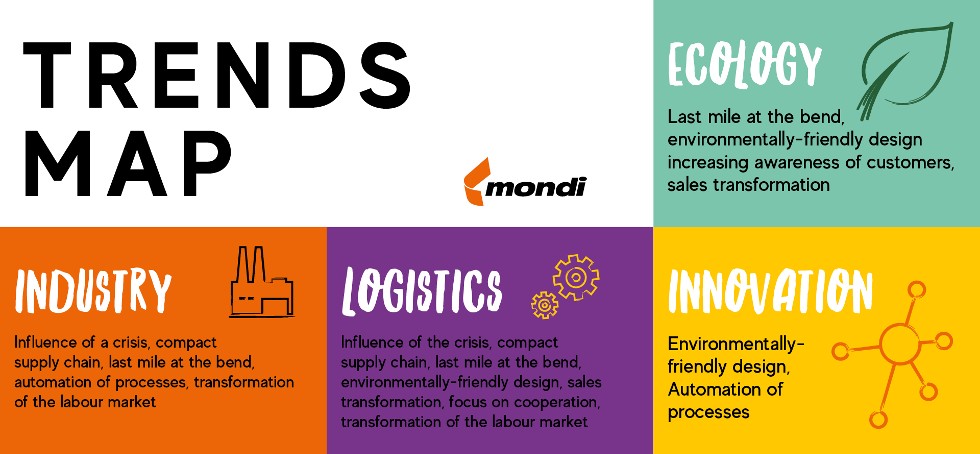

The map of current market trends can be found at the above website.

Below, we present that part of it which concerns this article.