From large central receiving hubs that pre-sort massive volumes of goods, to smaller distribution centres (DCs) handling ‘last-mile’ delivery, the Europe, Middle East and Africa (EMEA) post and parcel industry is dependent on the constant movement of goods from station to station, without delay.

The EMEA post and parcel industry has been overwhelmed in recent months by unprecedented growth, after years of incremental adjustments and upgrades to accommodate a steady 9% increase in volumes over a decade. But in just three months, the industry faced a staggering 40% increase in volumes, another 40% leap the next quarter, and then a growth rate of 25% throughout 2021.

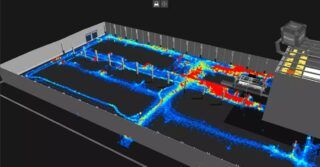

In what has been described by facility operators as a “350-day per year peak period”, the industry is now more reliant than ever on post and parcel operations running efficiently and reliably. If any link in the chain experiences an overload or a bottleneck, slowdowns ripple throughout the chain, causing problems and costly delays.

Whether it’s a giant blue-chip logistics company like DHL, UPS or FedEx with extensive automation or a rapidly growing post and parcel marketplace largely dependent on manual labour, existing infrastructures and processes simply cannot accommodate the surge in demand.

Material handling equipment (MHE) automation suppliers, system integrators, and developers of industry-specific software and control platforms are alleviating the EMEA post and parcel industry’s seemingly insurmountable challenges and pain points.

By design, scalable and modular automation solutions are giving logistics managers of any size facility and budget the power to address major system and process limitations, including: reliance on manual labour; the extremely limited workspaces found in the EMEA market; the proliferation of new types of product packaging; low accuracy rates; high returns; and frequent slowdowns and downtime.

With investments in advanced material handling solutions, smart robotics, innovative software platforms and analytics, post and parcel facilities of any size can be equipped to achieve higher levels of performance, order accuracy and throughput.

Cross-belt and sliding shoe sorters

Cross-belt and sliding shoe sorters are increasingly essential to post and parcel operations of any size. MHE automation suppliers have introduced cross-belt sorters designed to handle small to medium-sized, fragile and high-friction items with significantly higher discharge accuracy. High-density sliding shoe sorters offer fast, precise diverts of a variety of product and packaging sizes and types — from oversized boxes to polybags, providing gentle control and reduced impact speed, without compromising throughput or accuracy.

To learn more about what partnering with a major MHE automation supplier, system integrator, and developer of industry-specific software and control platforms like Honeywell can do for a business’ diverse demands for future growth and peak operational performance, visit sps.honeywell.com