The Chinese Weichai Holding Group Co., Ltd. has specialized, among other things, in the serial production of diesel engines. The subsidiaries of the Weichai Group concentrate on engine production for commercial vehicles, construction machinery, power generation and luxury yachts. WaldrichSiegen was able to assert itself in the fiercely competitive market– and has won four orders for a total of thirteen portal milling machines of the ProfiMill series in the last few years.

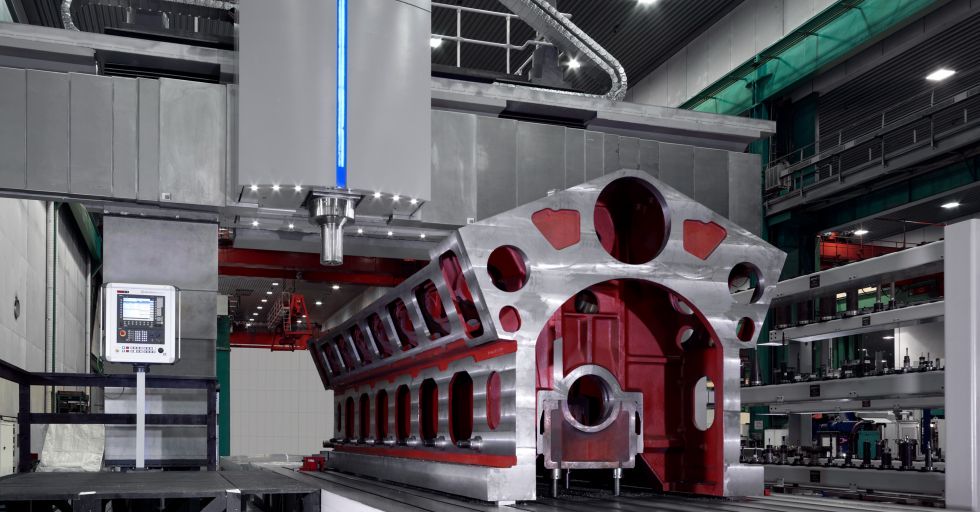

The latest order from Weichai Heavy Machinery Co., Ltd. comprises of seven identically designed ProfiMill portal milling machines with 2,750 mm clearance between columns, a tool changer for 320 tools, up to 10 different in-house manufactured milling heads and 76 kW milling power for the highly demanding machining of engine blocks. It was of great importance for the company to purchase all machines from WaldrichSiegen, as the customer relies and trusts in the interconnected systems and Industry 4.0 solutions of WaldrichSiegen and in the performance for high-efficiency machining.

The machines are equipped with extensive sensor technology for machine and process monitoring and are integrated into the customer’s Intelligent Manufacturing System. With a highly qualified teams in Germany and China for long-term service and lower costs for stocking of standard spare parts WaldrichSiegen offers the companies of the Weichai Group maximum productivity and a precise long-term accuracy of the machines.

The ProfiMill series inspires with its successful milling machine concept. During the development of the portal milling machine series, the focus was on a significant increase in power and torque for highest performance and at the same thime highest long-term accuracy. The ProfiMill was specially developed for the precise machining of XL workpieces. The ProfiMill compact with clearance width between 2,700 mm and 4,200 mm is the ideal portal milling machine for all users with small to medium-sized workpieces.

Photo: WaldrichSiegen

![Forecasts, Opportunities, and Challenges for the Polish Industry in 2024 [ANALYSIS] Forecasts, Opportunities, and Challenges for the Polish Industry in 2024 [ANALYSIS]](https://industryinsider.eu/wp-content/uploads/xIndustry-40-320x167.jpg.pagespeed.ic.o8zijDQlIJ.jpg)

![The importance of artificial intelligence in transport and automotive industry is growing [REPORT] The importance of artificial intelligence in transport and automotive industry is growing [REPORT]](https://industryinsider.eu/wp-content/uploads/xcity-320x167.jpeg.pagespeed.ic.xFkQdk7qXO.jpg)

![By 2030, the market size of metal processing tools is expected to reach $120.44 billion [REPORT] By 2030, the market size of metal processing tools is expected to reach $120.44 billion [REPORT]](https://industryinsider.eu/wp-content/uploads/xcutting-tools-320x167.jpg.pagespeed.ic.SgnEk-RWA-.jpg)

![Methane emissions remains elusive challenge for oil and gas industry [REPORT] Methane emissions remains elusive challenge for oil and gas industry [REPORT]](https://industryinsider.eu/wp-content/uploads/xMethane-emissions-by-source-320x167.jpg.pagespeed.ic.q-7jG2luXb.jpg)

![Will digital twin revolutionize the aerospace and defense sector? [REPORT] Will digital twin revolutionize the aerospace and defense sector? [REPORT]](https://industryinsider.eu/wp-content/uploads/xdigital-twin-in-aerospace-320x167.jpg.pagespeed.ic.K-YNPhggcS.jpg)