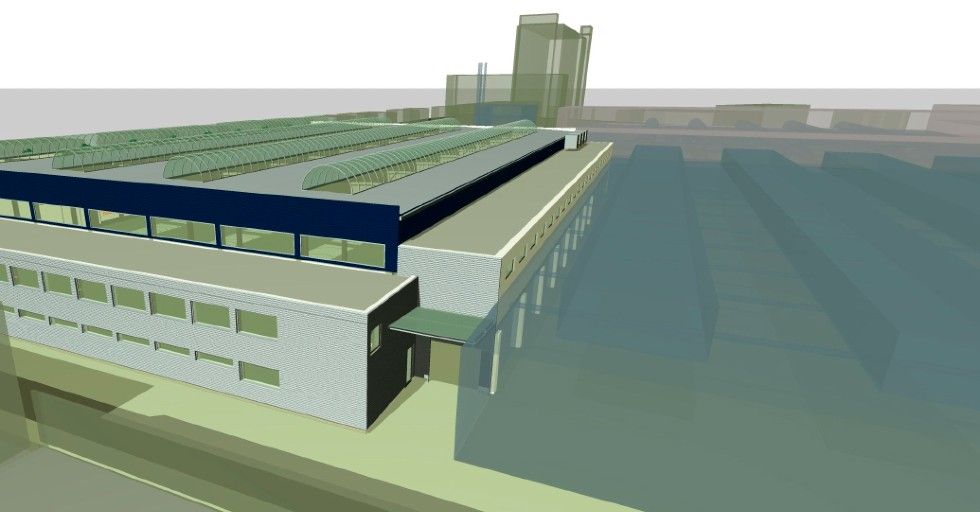

The company is expanding Šumperk manufacturing facility, with a new 4 500 sqm building, scheduled for completion in 2023.

The new hall will contain a two-storey space and annexes to greatly increase production of inserts. It will also allow room for upgrading the existing equipment in the current production floors at the site in the Czech Republic.

Along with developments to the manufacturing facility, the safety of employees will be improved. The new modern hall will feature additional changing rooms and clean spaces to maintain a safe working environment.

INNOVATION IN AUTOMATION & ROBOTIZATION

Innovations in automation and robotization are planned within the development to meet future demands. Also, by moving existing production into the new hall, we can update the equipment used across the facility. The use of automation will help streamline the processes involved in indexable manufacturing and increase production throughout the site.

With the environment in mind, they are also improving the sustainability of the Šumperk facility. The company goal is to globally reduce CO2 emissions by 50% and achieve recyclability of 90% by 2030.

The new hall will utilize photovoltaic panels installed on the roof to provide solar energy and reduce carbon emissions. There are additional plans for upgrading waste management capacity, including improved sorting to increase the reclamation of recyclable material.

Photo. Dormer Pramet

![Forecasts, Opportunities, and Challenges for the Polish Industry in 2024 [ANALYSIS] Forecasts, Opportunities, and Challenges for the Polish Industry in 2024 [ANALYSIS]](https://industryinsider.eu/wp-content/uploads/xIndustry-40-320x167.jpg.pagespeed.ic.o8zijDQlIJ.jpg)

![The importance of artificial intelligence in transport and automotive industry is growing [REPORT] The importance of artificial intelligence in transport and automotive industry is growing [REPORT]](https://industryinsider.eu/wp-content/uploads/xcity-320x167.jpeg.pagespeed.ic.xFkQdk7qXO.jpg)

![By 2030, the market size of metal processing tools is expected to reach $120.44 billion [REPORT] By 2030, the market size of metal processing tools is expected to reach $120.44 billion [REPORT]](https://industryinsider.eu/wp-content/uploads/xcutting-tools-320x167.jpg.pagespeed.ic.SgnEk-RWA-.jpg)

![Methane emissions remains elusive challenge for oil and gas industry [REPORT] Methane emissions remains elusive challenge for oil and gas industry [REPORT]](https://industryinsider.eu/wp-content/uploads/xMethane-emissions-by-source-320x167.jpg.pagespeed.ic.q-7jG2luXb.jpg)

![Will digital twin revolutionize the aerospace and defense sector? [REPORT] Will digital twin revolutionize the aerospace and defense sector? [REPORT]](https://industryinsider.eu/wp-content/uploads/xdigital-twin-in-aerospace-320x167.jpg.pagespeed.ic.K-YNPhggcS.jpg)