TECHNOLOGY DESCRIPTION

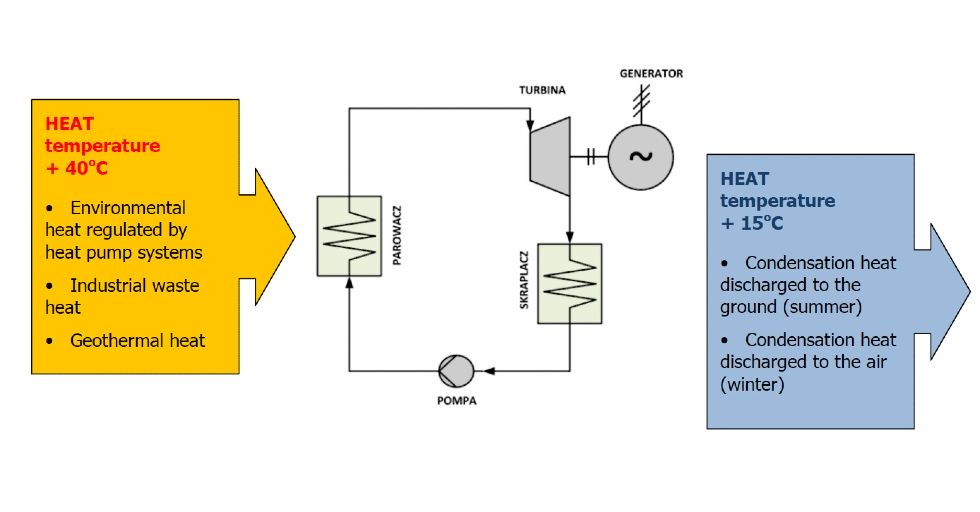

➡ The thermodynamic system TERYD is a classic closed circuit of a low-boiling refrigerant

➡ The refrigerant in the main circuit is characterized by high resilience parameters.

➡ The heat exchange systems (heat exchangers and heat pumps) supply heat to the main circuit in front of the turbine and extract the condensation heat from the main circuit downstream of the turbine.

➡ The efficiency of the system is very high, reaching 70%.

Efficiency of existing energy recovery technologies

The existing technologies of mechanical energy recovery from thermal energy (mainly technologies based on ORC cycles) are based on higher temperatures of heat sources. At the same time, in recent years the energy efficiency of new systems operating on low-boiling liquids in waste heat recovery processes has been increasing.

ORC technology is adapted to a wide range of applications, so now there are various possibilities of using ORC systems. By varying the working medium, modules can be produced specially adapted to the prevailing temperature level of the heat source, thus enabling the best possible system efficiency.

In high temperature applications (temperatures around 300 C), ORC systems have an efficiency of around 20%. Thanks to special solutions (unfortunately increasing investment costs), this efficiency can be increased to approx. 25%. In low temperature systems (temperature level between 90 C and 150 C) the efficiency is from 6% to 12%.

Turbine

The calculations of the thermodynamic system have been adjusted for the amount of refrigerant, that allows the correct operation of the turbine. The turbine is the heart of the entire system and an essential element in increasing the overall efficiency of the system. The turbine particulary efficient cools down the refrigerant causing the reduction the heat of condensation. The turbine model has been tested in CFD program: SOLIDWORKS Flow Simulation.

Automation of the system

The system include the following measurement systems:

– temperature and pressure measurements of working components upstream and downstream of the turbine,

– measurements and electronic regulation of V, A and frequency in accordance with the conditions of power operator.

Basic heat sources for the system

Renewable heat sources:

1. Geothermal

2. Biomass boiler houses

3. Biogas boiler houses (sewage treatment plants, landfills)

4. Heat from solar collectors

Waste heat:

5. Heat from industrial technological processes

6. Heat from cooling of ventilation air

7. Heat from waste incineration plants

8. Heat from condensate coolers (combined heat and power plants, power plants)

Thermal energy from excess electricity production

9. Energy from wind farms converted by heat pumps into heat in a thermal storage system

10. Energy from photovoltaic farms converted by heat pumps into heat in a thermal storage system

Ecological effect of the application of the system

Thermodynamic system TERYD is completely clean technology. This technology will allow the production of electricity without dust and gas pollution, which accompanies the generation of energy through the combustion of fossil fuels in traditional power plants and combined heat and power plants, as well as in most cogeneration systems.

The competitive advantage of the new solution consists in:

1\ a cost-effective and highly-efficient method of converting low-temperature heat (including heat of the environment) into the mechanical energy of the turbine, the efficiency of the system is very high, reaching 70%; this high efficiency of the new system is unique feature in the world technologies of converting heat into electricity

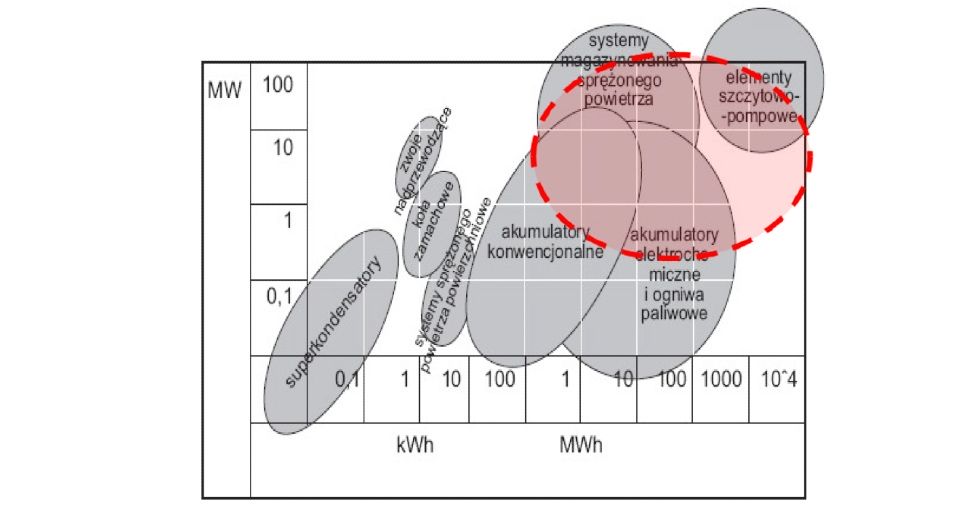

2\ the possibility of storing and recovering a large amount of energy available only for pumped storage systems and compressed air installations (→ diagram below): for this reason, the new technology is extremely desirable for energy groups and RES operators (energy storage from wind farms and PV)

3\ the new technology is completely harmless to the environment, extracts low enthalpy heat and converts it into clean (green) electricity;

4\ the service life of the technology is calculated for a minimum of 20 years (mainly the service life of heat pumps).

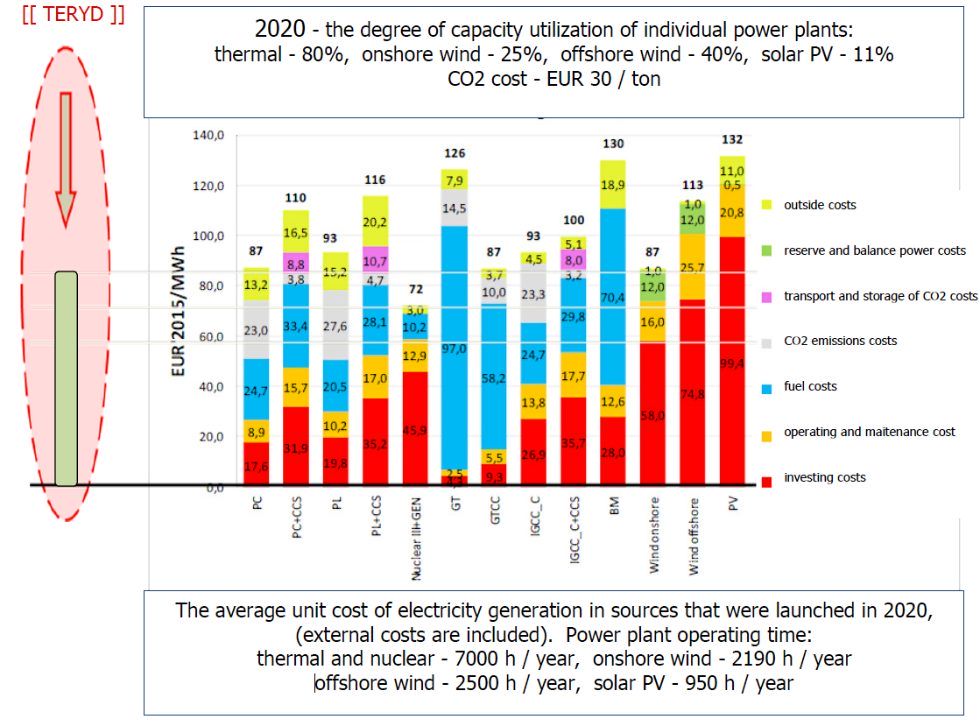

Average cost of energy generation taking into the external costs

The energy production costs for the TERYD technology compared to other energy production methods (based on: „Aktualizacja analizy por wnawczej koszt w wytwarzania energii elektrycznej w elektrowniach jądrowych, węglowych i gazowych oraz odnawialnych źr dłach energii”, ARE, Poland).

The analysis compared the following technologies:

– condensing power plants burning hard coal in pulverized coal boilers with desulphurization (DeSO2) and flue gas denitrification (DeNOx) (PC – pulverized coal) installations,

– power plants with pulverized coal boilers and CO2 capture and storage installations (PC + CCS),

– condensing power plants burning lignite in pulverized coal boilers with DeSO2 installations and DeNOx (PL – pulverized lignite),

– power plants with lignite-fired boilers and CO2 capture and storage installations (PL + CCS),

– Generation III+ nuclear power plants (Nuclear III+ GEN),

– Generation IV nuclear power plants (Nuclear IV GEN),

– gas-fired power plants with a hard coal gasification installation integrated with the power plant (IGCC_C – coal integrated gasification combined cycle),

– power plants with an integrated hard coal gasification installation and holder installations and CO2 storage (IGCC_C + CCS),

– gas-steam power plants fired with natural gas (GTCC – gas turbine combined cycle),

– gas turbines (GT – gas turbine),

– biomass power plant (BM),

– wind farms on shore (wind on-shore),

– offshore wind farms,

– solar power plants (PV – solar photovoltaics).

In our opinion, this study underestimates the real costs of nuclear power plants.

The cost of the TERYD technology TERYD does not include fuel (fuel is environmental heat or waste heat). For this reason, this technology is comparable to wind & solar power plants (no blue bar in the chart below). It differs from them by working independently of the weather conditions, it works day and night 24 hours, 360 days a year with predictable and – more importantly – fully controlled power.

![Methane emissions remains elusive challenge for oil and gas industry [REPORT] Methane emissions remains elusive challenge for oil and gas industry [REPORT]](https://industryinsider.eu/wp-content/uploads/xMethane-emissions-by-source-320x167.jpg.pagespeed.ic.q-7jG2luXb.jpg)