The manufacturer of drive elements, boasting a 140-year tradition, is planning a market expansion in the area of large-size devices. At the same time, it is constantly increasing the sales of its products on global markets.

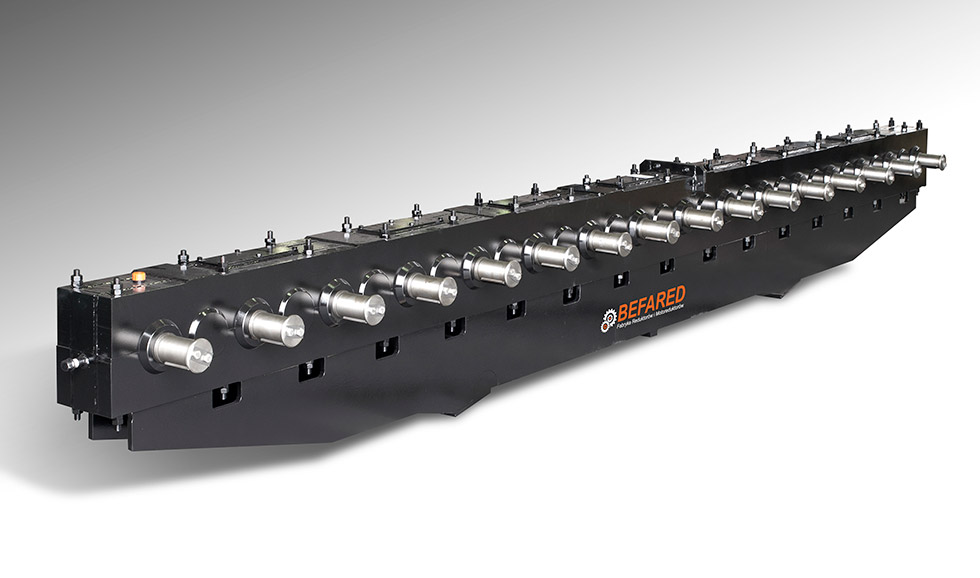

BEFARED SA from Bielsko-Biała is currently the main producer of general purpose reducers and geared motors on the Polish market.

This fact is due, inter alia, to many years of tradition in the production of drive elements in its plant, which has been in existence for almost 140 years. However, it should be emphasized that in recent years it has not been tradition that has the greatest importance for the functioning of the company. Currently BEFARED is not associated only with universal and catalog gearboxes, but with the ability to adapt production to the needs of each customer.

1.5 million pieces of reducers and geared motors for five thousand recipients

“We have extensive experience in various areas of machining, including in hobbing of toothed elements, in machining of cast iron and steel bodies on CNC centers, thermo-chemical treatment, chiselling and turning. The variety of technologies we use means that we are actually self-sufficient, as we are able to make most of the elements using our own production facilities and bypassing subcontractors – says Mariusz Chęciński, President of the Management Board of BEFARED, and adds: – Currently, the company offers five basic types of gears ( H, NR, BBLine, EM and Universal). In addition to the products from the catalog, we offer all kinds of special gears and devices developed according to the documentation prepared by the customer’s construction and technology department and on the basis of his documentation ”.

The knowledge and experience in the field of general purpose reducers and geared motors, which the company from Bielsko-Biała has at its disposal, enables, among others production of gear reducers with a wide degree of standardization, typification and unification. A great advantage of the company is the possibility of various applications of its products, despite the small number of parts and assemblies. The company is able to produce specialized elements using semi-automatic team machine tools and processing lines, so the technology is the same as in the case of serial production conditions.

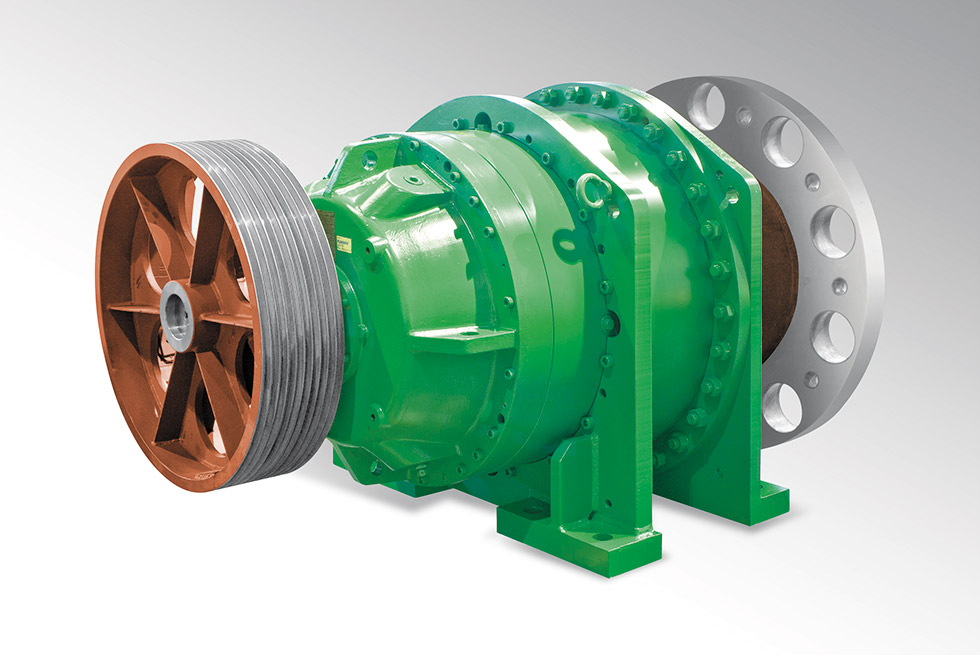

So far, the company has delivered about 1.5 million pieces of its products to over 5 thousand buyers in Poland and abroad. As reducers and geared motors manufactured by BEFARED are the basic element of drive units, they are widely used in many types of devices operating in all industries. “The elements we manufacture work in the steel, energy, mining, coke, food, chemical, etc. industries,” says Mariusz Chęciński and adds: modern series of BBLine geared motors, as well as H reducers and geared motors with an extended offer. At the same time, we are able to adapt each of our products to specific customer requirements. We also offer the possibility of designing special drives and an efficient service. All these elements make our devices able to fully meet the expectations of the most demanding users of reducers and geared motors ”.

Continuous optimization of machines and devices forces the manufacturers of drives to adapt to the building conditions. Therefore, the company has been specializing in the design and production of non-standard applications for several years. Therefore, it is not surprising that the company’s domain has become high-power drive units and special gears adapted to the requirements of customers. What is important from their perspective – qualified construction and sales staff provide technical advice so that each subsequent user can use the drive in his production process without any restrictions.

Specialists in unusual solutions

“We estimate that we are currently the leading Polish producer in our industry. We have a good and well-established position on the market, supported by 140 years of tradition. At the same time, BEFARED is becoming an increasingly recognizable brand when it comes to special transmissions. We are constantly gaining the market by expanding our offer for new industries, such as wind farms, as well as the offshore industry. We focus on exports, not forgetting the domestic market, where the company has a stable position as a manufacturer of industrial gears, argues the President of the Management Board of BEFARED. – Despite the difficulties and the lack of investments on the Polish market, the company increases its sales every year, focusing on more and more new markets. Exports to Germany, France, Italy, Belarus and Morocco play an important role. We are investing in industrial infrastructure to increase the possibilities of large-scale production. We also do not forget about low and medium power geared motors ”.

The fact that export is an important element of the sales structure of the Bielsko-based company is evidenced by the fact that its products are delivered to many countries in Europe, Asia and Africa. Among them there are, among others Czech Republic, Slovakia, Slovenia, Hungary, Bosnia and Herzegovina, Netherlands, France, Egypt, Germany, Lithuania, Ukraine and China. In addition, in 2013, the subsidiary BEFARED India was established, operating in the Republic of India and having its headquarters in Mumbai. Its main activity is the production and sale of the company’s products in the Republic of India and the United Arab Emirates. As a result, it was possible to establish cooperation with clients representing the food, chemical, energy and mining industries in the Far East market.

One of the basic reasons why the company successfully acquires new customers and gains new markets is the technical ability to manufacture various non-standard devices. A good example of this is the production of a plug for the drain hole of a blast furnace at the Bielsko-Biała plant at the turn of 2015 and 2016. In this case, the originality of the task was based on making a plug on the basis of archival documentation from the 1970s and adjusting the dimensions to newer plugs at the blast furnace at the ArcelorMittal steelworks in Dąbrowa Górnicza.

Another solution that the company can certainly consider as its success is a set of lignite screening screens, used to feed boilers, which was made for one of the Polish power plants. In this case, the drive units are driven by angular gears specially designed for this purpose, which in turn work thanks to electric motors using torque converters and BEFARED clutch. The drive units are adapted to work with a diagnostic system that monitors vibrations on bearing nodes, transmission temperature and power consumption by electric motors. Such a system allows the facility’s staff to carry out inspections and repairs of drive units before any serious damage to the components transmitting the torque occurs.

“We have many interesting and prestigious projects under our belt. The successes include equipping the haulage devices from the Stefanów Field and installing the gears on the devices of the new Zakład Przeróbki Mechanicznej Węgla at Lubelski Węgiel “Bogdanka” SA, which we implemented in 2010–2014. A big challenge, also successfully completed, was the equipment with reducers and the assembly of the aluminum rolling line, which is currently operating in Egypt. Another interesting task was the modernization of the drive systems for stacker-loaders for ArcelorMittal in Dąbrowa Górnicza. It included the replacement of drives with the installation of full automation. This ensured trouble-free operation and compliance with the highest health and safety standards. Of course, these are just a few examples of unusual implementations, because in recent years the company has made a number of interesting applications that deserve recognition – emphasizes Mariusz Chęciński and adds: – The company’s flexibility and willingness to use additional, innovative solutions allow it to maintain a strong position on the market. This is reflected in the increase in sales of our products, both to domestic and foreign recipients ”.

At full speed

In connection with the expansion plans to newer and newer markets, the management board of BEFARED decided to build a new production hall in the near future, which will allow for the production and repair of gears and devices with a weight over 25 tons. This fact will certainly enable the planned development on the market of large-size drives . At the same time, the company is constantly expanding its technological capabilities both in terms of production and modernization of its products.

“The constantly modernized machinery park, supplemented with machining machines representing the latest technical solutions, provides us with the highest level of manufactured gears. We can produce 5 MW toothed gears. Offered gears can be made with hollow and solid shafts, mounted on feet or flanges, and also equipped with various types of mechanical and electrical equipment. Toothed elements are produced up to a diameter of 2 m from materials that are carburized, nitrided or induction hardened – says the president of the board and specifies: – The most important profile of the company’s activity is the production of gears, therefore the main goal of technology development is the efficient production of toothed elements and components of gear bodies toothed gears. We are working on optimizing the milling of toothed elements using the envelope method, consisting in the selection of appropriate cutting parameters, cooling agent, cutting tools and PVD coatings in order to minimize tool wear, taking into account the required quality of details. We also strive to develop the technology of thermo-chemical treatment with the use of nitriding technology, as well as carburizing and low-pressure hardening ”.

The fact that the planned development of BEFARED technology is not so much real, but even certain, is due to the fact that the team of engineers employed in the company is still working at full capacity. Currently, their activities are focused primarily on the implementation of modern technologies in various areas of manufacturing components for toothed gears. The main assumption of the company’s strategy in the area of implementing modern technological solutions is to shorten the processing time while maintaining the lowest possible expenditure on tools, so as to obtain the best ratio of production costs to the price of the finished product. The work of the company’s specialists is aimed at searching for optimal solutions. The effects of these works will certainly once again increase the company’s competitiveness and will allow to obtain funds for research and innovative technological solutions. “The priority of BEFARED is to meet the expectations and needs of customers through the continuous development of the company and improvement of the quality of products and services offered. Only effective and continuous improvement gives us the opportunity to develop the company – sums up Mariusz Chęciński. – The implementation of modern technologies, offering new and modernized products with the simultaneous and systematic improvement of employees’ qualifications is our goal, which we consistently pursue. At the same time, and it is worth emphasizing, the guarantee of our quality policy is the awareness of the company’s employees that each of us is responsible for the quality of services and products ”.