The Jastrzębie-based company ELPLAST +, operating on the Polish market since 1999, is a family company operating in the processing and production of plastic products, mainly made of polyethylene and polypropylene. Despite the huge competition, the company has a high demand for its products, especially in the mining industry and in the road and municipal sector.

For 18 years, ELPLAST + has been supplying the market mainly with PE pipes (ordinary and armored), PE fittings, sewage chambers and water meter chambers. For the needs of industry and mining, it mainly produces pipes: anti-static, flame-retardant PE, PE and Victaulic fittings (grooved system for joining steel pipes, providing several times faster assembly than welded or flanged installations). ELPLAST + also realizes orders for the water sports and recreation sector to a slightly lesser extent. These are mainly floating docks and inrun ports for water scooters.

The company from Jastrzębie has completed many large investments with a total value of over PLN 5 million, such as: a modern line for the production of multilayer armored pipes in the diameter range of 90-400 mm, a modern, high-performance regranulator offering the possibility of dyeing and a modern brand pulverizer Pallmann.

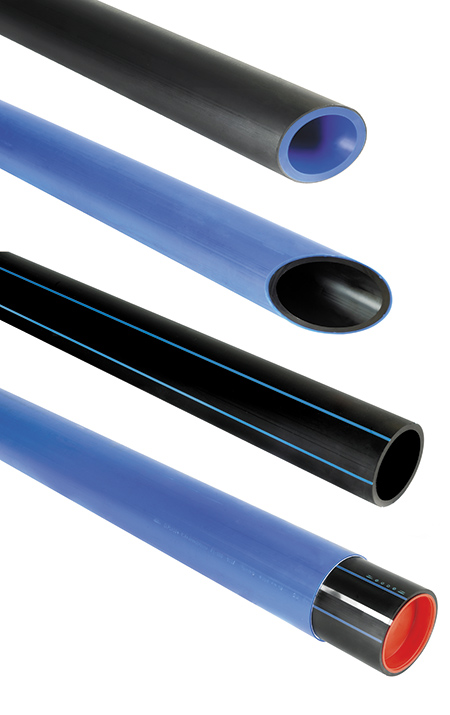

Multilayer pipes and pipes with protective armor

The production of armored pipes includes the production of multilayer pipes (co-extrusion) and pipes with a protective armor (not molecularly connected to the base pipe). In both cases, it is possible to apply appropriately modified raw materials that affect the final properties of the product. In this way, it is possible to produce a pipe that will additionally be antibacterial, antistatic, flame-retardant or resistant to higher temperatures.

By co-extrusion, it is possible to produce a pipe with up to four layers. Each layer can be independently modified and have specific properties, e.g. on the inside – antibacterial, on the outside – flame-retardant and antistatic. Important in this process is the use of raw materials modification that allows for their mutual compatibility. During production, particular attention should be paid to the centricity and stability of the thickness of individual extruded layers, and the extrusion technological process should be carried out in such a way that the expected properties of the raw materials are not degraded.

A product consisting of a base pipe with the required properties and a protective armor is called an armored pipe. This armor can only protect the base pipe during assembly with the use of modern renovation techniques or have special properties obtained through the modification of raw materials.

The armored and multi-layer ELPLAST + pipes are made of polyolefins – a material that is used extensively all over the world. Polyolefins are characterized by very good mechanical and strength properties, resistance to internal pressure, very good weldability, durability, resistance to impact, corrosion and the action of many chemical compounds. Moreover, these pipes are light, smooth, flexible, biologically inert and approved for contact with drinking water

ELPLAST + offers a wide selection of armored pipes made of PE 100 RC type material with exceptional strength properties and high resistance to point pressures. They are also characterized by high resistance to slow crack propagation (FNCT Full Notch Creep tests) according to ISO 16770 and notch test (Notch Test) according to PN-EN ISO 13479. They work very well in pressure installations (Specjal type armored pipes, Duo Specjal, Mono Specjal). These properties are obtained through the use of appropriate market raw materials or raw materials based on ELPLAST + own recipes.

A dynamic but difficult market

The value of the dynamically developing market of ELPLAST + plastic pipes is estimated at approximately PLN 2.7 billion. The key trends that will have an impact on the development of the industry in the near future are: dynamic growth of B2B eCommerce, multi-channel communication and distribution – development and growth in the use of mobile devices, integration of systems of suppliers and service recipients, co-creation of services / products, decline in brand loyalty, as well as the companies’ care for the greatest possible availability and quick delivery of services / products.

The company sees its chance primarily in potential infrastructural and construction investments related to the new financial perspective of the European Union for 2014–2020. The size and absorption of foreign markets is also important, which is why the Jastrzębie company is planning to expand into new foreign markets in the near future, although it is already exporting its products to the Baltic countries, the Czech Republic, Slovakia, Hungary, Germany and Scandinavia. At the moment, the company is carrying out, inter alia, an investment for one of the Swedish recipients. The value of the contract for the construction of sewage tanks is over PLN 1 million. The company’s current investments include: a modern PP-R production line, where the goal is to increase the production capacity of pipes with a diameter of 16-63 mm. The investment is carried out in two stages, and its total value is PLN 2 million. The currently implemented project of implementing a new ERP system worth approx. PLN 1 million is aimed at improving processes in all areas of the company’s operations, especially in the area of logistics and production.

The main threats that may have a key negative impact on the company’s development are the political and economic situation in Poland, leading to a further collapse in public investments. Factors such as a further decline in construction production, an increase in operating costs, especially in terms of the main cost, which is the raw material used for production, as well as aggressive competition actions resulting directly from the potentially difficult market situation, are also troublesome for companies operating in the industry.

Consulting and laboratory quality

The competitiveness of ELPLAST + is based on very strong foundations, which are: the model of individual customer service, high-quality products, reliable advice and customer loyalty. The company’s know-how consists in applying its own technological solutions during production. As a result, it is based on the developed processes and modifications of the physicochemical properties of raw materials. It is possible, among others, due to the fact that the company has its own laboratory. Thanks to it, the quality of products is subject to constant control. In the laboratory there are, among others, research on raw materials used by the company and analysis of their properties. Tests carried out in ELPLAST + laboratories result from the requirements for products, as well as the desire to provide high-quality products confirmed by compliance with PN-EN, PN-EN-ISO standards, technical approvals, safety certificates and meeting customer requirements. Moreover, such tests guarantee the company a quick and positive certification in accredited external institutions.

As part of the search for better and better technological solutions, the company also cooperates with many research units, in particular with the Polish Academy of Sciences in Łódź, the Institute of Polymer Materials and Dyes in Gliwice, the Central Mining Institute in Katowice and the Oil and Gas Institute in Krakow.

The research conducted by Kantar Millward Brown on the level of loyalty and satisfaction with cooperation with the Hawkish company indicates that it is twice as high as the results represented by the market. For 60% of customers, ELPLAST + is the main supplier, and almost half of them are very loyal people who want to constantly cooperate with the company and are strongly attached to it. It is also worth noting that 71% of recipients are individually looked after by traders, while the market average is at the level of 31%.

![Methane emissions remains elusive challenge for oil and gas industry [REPORT] Methane emissions remains elusive challenge for oil and gas industry [REPORT]](https://industryinsider.eu/wp-content/uploads/xMethane-emissions-by-source-320x167.jpg.pagespeed.ic.q-7jG2luXb.jpg)