Kongsberg Automotive opens its third production plant in Poland. In 2016, the holding expanded its factory in Pruszków and opened another one – in Koluszki. It is clearly visible that the Polish branch of the concern is becoming more and more important for a globally leading manufacturer of the automotive industry.

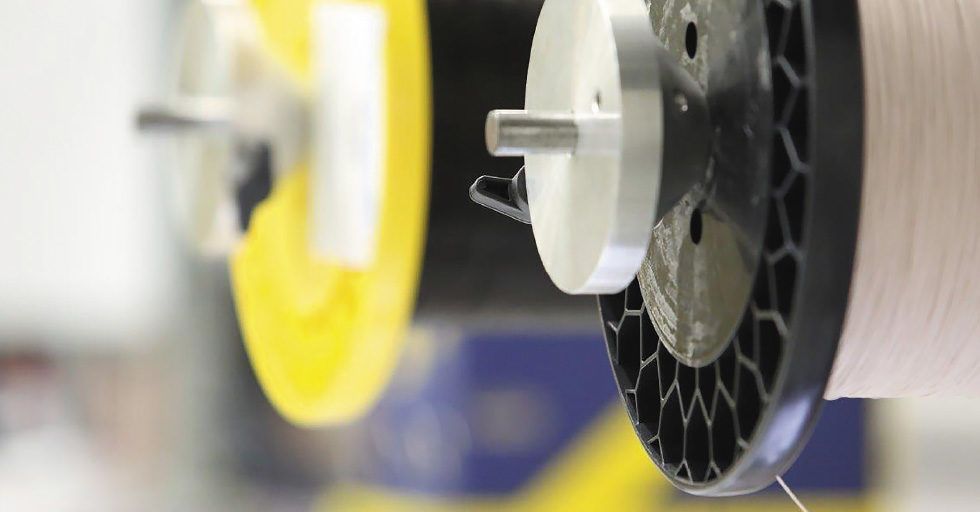

“The project is actually entering its final phase. At the turn of 2017 and 2018, the building of the new plant will be put into use. Two completely new machines have already been installed at the factory. A part of the existing production process is also scheduled to be moved to December. In addition, operators and engineers from Brest are currently trained in Pruszków – says Frederic Kot, general director of Kongsberg Automotive Interior Polska. And he adds: The main products manufactured in the factory in Pikutkowo near Brześć Kujawski will be advanced heating mats for car seats of the best global car manufacturers.

Production starts

The new factory of the concern specializing in the production of components and parts for the automotive industry is located in Brześć Kujawski near Włocławek in the Kuyavian-Pomeranian Voivodeship, in the Brest Economic Zone. Important elements of choosing this location from the investor’s point of view are the immediate vicinity of the A1 motorway junction, opening the automotive market, as well as good communication with the company’s existing plants in Pruszków and Koluszki. According to the company’s plans, the annual turnover of the plant will amount to EUR 80 million. The facility has over 10,000 sq m of space. The estimated value of the investment is PLN 150 million. The new factory will mainly produce car accessories, i.e. heating mats, pipe and hose sets for drive units, braking and fuel systems, etc.

A thousand people are expected to find employment in the new factory. This year, it will employ nearly 100 people who are undergoing specialist training at the Pruszków plant. In 2018, another 400 people will be employed. The factory is to achieve full employment in 2020. This fact is important from the perspective of the Kujawsko-Pomorskie Voivodeship, where the unemployment rate has reached 20% in recent months. The first recruitment of employees was related to the hiring of, among others, process and quality engineers and technicians, automation technicians, maintenance technicians, assemblers, machine operators, as well as warehouse and logistics specialists.

An extremely important point of reference for the company’s employees is that the plant has been designed and developed in accordance with the World Class Manufacturing concept. “The entire material flow and all production processes are aligned with lean manufacturing” says Frederic Kot. – In addition, at the plant, the equipment transferred from Pruszków will constitute less than 50% of the machine park, and the main part of the production process will be based on completely new machines and production lines, which will represent the next generations developed by industrial engineers.”

The new factory will have both production lines, which will include a manual assembly process, as well as semi-automatic and fully automated robot lines. Employees will carry out all production processes in accordance with the Kaizen philosophy, which has its roots in the Toyota concern, which is based on the process of continuous self-improvement of each employee and all elements of the production process. In this way, in accordance with the Japanese production philosophy, the plant of the Norwegian concern developing the latest technologies in its industry in Poland will operate. “In the following years, we plan to implement innovative solutions in Brest, which are currently not available on the automotive market. At the moment, we are researching and working on improving our ideas and prototypes” emphasizes the company’s CEO.

The concern invests in Poland

“Taking into account the assumptions of the global strategy of Kongsberg Automotive in Brest, new projects will be developed, launched and implemented, which will become available to road users in the coming years. In addition, some of the already existing technological solutions will be transferred and implemented to the factory in Pruszków, explains Frederic Kot and adds: customer needs”.

Actions aimed at the effective implementation of the company’s strategy, which continues to increase its profits, also influenced the development of its Polish branch. Therefore, part of the production of seat heating systems will be transferred from the factory in Pruszków to the new plant in Brześć Kujawski. At the same time, the Mazovian plant will focus on the production of pneumatic systems. As Frederic Kot emphasized during the announcement of the plans to build a new factory near Włocławek: “The decision to establish a new plant in Poland is dictated by the high growth rate of plants operating in this area. The factory in Pruszków employs over 1.2 thousand people today. people. The planned dynamics of revenue growth is 80% within 5 years. All the time the company signs new contracts for the supply of heating mats and massage systems for car seats ”.

The plant in Pruszków, which has been operating since 2000, has increased its capacity by a new part with an area of 2.5 thousand square meters. At the same time, the expansion, the cost of which amounted to PLN 3 million, is associated with an increase in employment by 20% by 2019. The specialists sought by the company include, among others automation engineers and robotics specialists. The factory in Pruszków is systematically equipped with new technological lines. “We decided to enlarge the plant in Pruszków in order to create and expand areas for the needs of production and new projects, and thus, launching new production lines. Such an investment gives us an increase in production of EUR 40 million” said Frederic Kot.

The manufacturer’s pace of development in Poland is evidenced by the fact that last year the concern not only expanded the factory in Pruszków, but also opened another production plant in Poland, located in Koluszki near Łódź. At the moment, on an area of 6,300 m2, components for trucks of manufacturers such as Scania, Volvo, DAF are produced. The plant, which employs about 150 people, uses technological solutions tailored to the 21st century. The production processes in the new Kongsberg Automotive facility will be automated and mechanized. Most of the work that requires precision – such as machining, forming, hardening and assembly – will be performed using industrial robots. In a separate production and warehouse area (1,000 m2), the technology used ensures control of air humidity and its maintenance at the level of approx. 50%. Additionally, ventilation was increased (up to two changes per hour and up to 4 m), and epoxy floors were used.

Increase driving comfort

The key justification for investments in Poland – apart from the development opportunities offered by the Polish market at the moment – is certainly the fact that Kongsberg Automotive concludes further large contracts with the largest car manufacturers in the world. Last year, the plant in Pruszków won, among others a global tender for the production of heating mats for premium cars of one of the largest German manufacturers. At the same time, the plant will implement another contract involving the production of heating mats for armrests and side door panels for premium off-road vehicles. The value of this order is estimated at PLN 120 million.

It is worth looking at the reasons for the global success of the company dealing in the production of components and parts for the automotive industry, which can be divided into three main groups: pneumatic lumbar support and massage systems for car seats, heating systems for car seats (so-called heating mats) and elements of the car seat ventilation system. “During the production process of all our elements, we focus primarily on safety and quality. We have the ability to adapt the proposed solutions to the individual needs of customers, in accordance with all safety rules – emphasizes Frederic Kot and adds: – When thinking about product groups, we can certainly find many similarities, but we treat each product as a separate technical project. Our competitive advantage is certainly the latest technology that we offer on the market. Thanks to it, we can introduce the latest technical solutions to the market, so as to increase driving comfort day by day. This is the main goal of our activities.”

Thanks to this, the concern, which celebrates its 50th anniversary this year, has become a leading producer in its industry. This is evidenced by the fact that the holding currently employs over 11,000 people worldwide. employees. The company also has 43 production plants in 20 countries around the world located in Europe, both Americas and Asia.

![The importance of artificial intelligence in transport and automotive industry is growing [REPORT] The importance of artificial intelligence in transport and automotive industry is growing [REPORT]](https://industryinsider.eu/wp-content/uploads/xcity-320x167.jpeg.pagespeed.ic.xFkQdk7qXO.jpg)