Is it possible for a small Polish company to produce advanced equipment that only large Western companies are prepared to produce? Yes, because in an industry where unconventional ideas count, companies often prove to be too inflexible.

If you were to use just one word to describe all the machines designed and built by Welmasz specialists, it would undoubtedly be “unique”. They are designed to meet specific requirements and are often produced in only one copy. Although their design is different each time, the work they do is usually a combination of precision and repeatability, on a scale and at a speed that can change the development dynamics of the companies that order them.

Do you want to package 200 buns per minute, glue a wooden frame in two seconds, or package medicine for an inhaler with technology that even the world’s largest pharmaceutical conglomerate would be proud of? Then you’ve come to the right place.

THE WAY TO INDEPENDENCE

The story of an innovative company, whose production hall is now located in Piaseczno, began in 2009. At that time, Robert Welik, a 32-year-old graduate of Mechanics and Mechanical Design at the Bialystok University of Technology, was already working on the design of machines for several companies.

“The German company I was working for at the time ran into problems. The main reason was the crisis in the global markets, which was aggravated by the serious illness of the owner. The company was failing, and as an employee I was just starting to work on a large project for a machine that would complete the production line of a Czech food company,” Welik says. “I had the idea to do the project independently. I thought: this way the customer won’t lose the advance payments he has already made, and I will complete my first order on my own account and be able to continue working in my profession.

The idea was a hit. Welik was able to convince the Czech company’s owners that he could complete the project originally entrusted to his former German employer.

This led to the creation of Welmasz’s first product, a machine that rolls sliced meat into tubes, fills them with vegetable salad and packs them in pairs in special boxes, taking its name from the founder’s surname.

Welik’s last employer was a German conglomerate specialising in the production of industrial slicers. Projects that complemented the production line added value to the company. Designing and building the continuation of the line – tailored to the producer’s needs – was also an interesting market niche to exploit. “This was the beginning of my adventure with my own company. As I had been working in the industry for years, the first project led to enquiries and then orders. I had always wanted to be independent, but I didn’t expect to give up my day job so quickly,” admits Welik.

MACHINES TAILORED TO YOUR NEEDS

In the early stages of the company’s development, the founder of Welmasz relied on established contacts he already had. Tasks requiring specialist programming skills were outsourced to a company he had previously worked with. He also began to look for the right people to join his team and help grow the business. Such an opportunity quickly arose when the Thomson company in Piaseczno closed down and Mirosław Sochacki – a maintenance specialist with 25 years’ experience – became available. Welik offered him to work on its project. Sochacki agreed and took responsibility for assembling the machine ordered by the Czech company.

This situation outlined the model in which the newly formed company began its activities. Welik prepared the project and Sochacki was responsible for its assembly. Mechanical components and the control system were manufactured by external companies.

The Polish-Czech project proved to be a success for Polish engineers. A year after Welmasz was founded, the first creation was put into operation.

By then, Welmasz was already working on another order from a packaging manufacturer – Zeller Plastic Poland, based in Garwolin. The company asked Welik to develop a device for testing the tightness of roll-on bottles. The project was successful and soon three more such testers were produced in Piaseczno.

“At this stage of my company’s development, I needed support from the programming side. That’s why I started working with PRO-CONTROL, a company specialising in industrial automation. They had never dealt with building machines from scratch before, and I needed specialists who could write the right software and build control cabinets for a given machine. We complemented each other on the market,” says Welik.

Thanks to its contacts in the market, PRO-CONTROL was able to win more orders, in which Welmasz was able to prove itself as a subcontractor, designing the entire process according to the customer’s needs.

Another important order came from the Oskroba bakery. “Oskroba ordered a system from us for packaging filled rolls. Our aim was to create a machine that would pack buns into cartons at a rate of 200 buns per minute. This enormous efficiency was obviously the biggest challenge of the project. The line had to be fully automatic, not only for packaging but also for the logistics of empty and full boxes,” explains the Welmasz boss.

The success of this project brought another order from the bakery industry – from the Warsaw Bakery and Confectionery Cooperative (SPC). The order was for a system to be installed at the oven to remove baked loaves from the moulds and transfer them to a cooler, while at the same time sending the moulds in the opposite direction. 1,500 moulds were to be arranged on a special platform, from which they would also be automatically loaded for another cycle – filling with dough. The machine was designed to produce 16 loaves every 20 seconds, almost one loaf per second. The machine was built and is now in operation at SPC’s premises on Krakowiaków Street.

The next customer, Padma Art from Suwałki, which among other things produces one of the most popular picture frames sold by IKEA, turned out to be very important for the company’s development

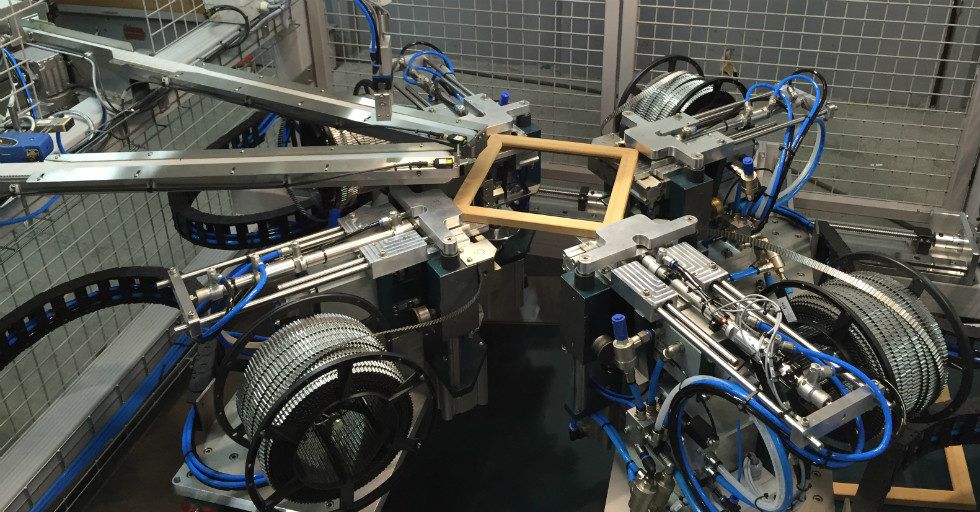

“The company wanted to switch to a new technology for joining the four strips that make up a frame. Instead of stapling, they wanted to glue them together with a super-strong adhesive. Our task was to design and build a highly efficient machine that would glue the next frame every two seconds, or about 30 frames per minute, while maintaining high quality joints,” explains Welik.

PRO-CONTROL was a partner in the project. IKEA approved the machine designed by Welmasz, which is still producing frames in Suwałki. The designers achieved a speed of 1.8 frames per second.

The machine, which glued frames for IKEA at breakneck speed, was a major success for the small but ambitious company from Piaseczno. Welmasz was proud to present its solution in meetings with potential customers.

Soon after, another challenge arose. Celon Pharma ordered a complex piece of equipment from Welmasz that no one else in Poland was willing to undertake. It was a machine that would roll a narrow blister of tablets in a specific way, position it in relation to the tablets and attach it to an inhaler. Until then, only one German company had such a machine, and it guarded its technology closely. The Polish pharmaceutical manufacturer decided to produce this inhaler for asthma sufferers because the patent on the solution, previously held by one of the largest Western pharmaceutical groups, had expired.

“The biggest challenge in this project was the correct positioning of the blister with the tablets and efficiency. During the process, each blister is cut, the cut pieces are fed up a level, one end is rolled and the other is split and positioned correctly. Only then is it placed in the inhaler. The customer wanted the machine to fill seventeen inhalers per minute,” says Welik.

A complex mechanism was created based on more than 20 servo drives or motors that control the feeding. It’s worth adding that the machine carries out a process so complex that it cannot be done by hand. Shortly after the first machine was commissioned, the customer ordered a second one.

THREE HEADS ARE BETTER THAN ONE

“From the very beginning, Mirek Sochacki and I got along perfectly. If I could, I would clone him,” laughs Welik. When another order for inhaler filling machines came in, this time from Polfarmex, Welik decided to dispense with PRO-CONTROL’s support and set up his own programming department. Of the two programmers initially hired, 28-year-old Maciej Całczyński stayed with the company permanently, having moved from Poznań for the new job.

Welik describes him as a “programming virtuoso”. Thus was formed the core of Welmasz, which for two years operated like a well-designed machine. “I create the design for the machine ordered, we order the necessary components from other manufacturers and subcontractors, the control cabinet and software are created according to Maciek’s design, and Mirek assembles and checks the mechanical elements. We consistently cooperate with PG System Piotr Gierda, which assembles and wires the machines for us,” explains Welik, explaining the company’s philosophy: “Our uniqueness lies in the fact that, among small companies, we are certainly one of those with the best ideas. That’s our greatest asset. Instead of offering the customer a ready-made robot, which is often too advanced and expensive for the task to be performed, we propose a dedicated and optimal solution, which is sufficient for the customer’s needs, but not overdone,” explains Welik.

He adds that Welmasz does not want to grow by force, but wants to stay in its market niche. That is why they build several machines a year that require very large budgets (often more than two million zlotys), which is perfectly sufficient for the smooth operation of the entire company.

“Because we don’t work on the basis of quantity, we can carefully think through each project, select and apply technologies that will ultimately be cost-effective for the customer. We make sure that our client does not over-invest, that the introduction of a particular machine into their production line is profitable and that the construction costs are recouped within a given period of time,” says Welik.

Welmasz machines are products that are perfectly tailored to the customer’s needs. An example is a machine designed for a confectionery company. The market offers simple machines that produce aluminium chocolate cups. However, there is no machine that can switch between making cups and cones, depending on the current demand. Such a machine is currently being developed by Welmasz.

“Often our role is not limited to building a specific piece of equipment. If there is a need, we also advise on how to organise the production flow in order to optimise it. It’s not profitable for big companies to adapt their machines for one customer, because it’s always risky, and we’re willing to take that risk,” Welik concludes.

This philosophy is bearing fruit – customers are coming back with repeat orders. However, as the Welmasz founder admits, customers are sometimes initially sceptical that three specialists in a small hall in Piaseczno can build such advanced machines, which are usually produced in the assembly plants of large Western corporations.

“Sometimes this is a barrier. The customer does not see our background, so he wonders whether he should trust us and invest hundreds of thousands of zlotys in a project. However, our biggest argument is certainly what we have achieved so far,” says Welik.

![Forecasts, Opportunities, and Challenges for the Polish Industry in 2024 [ANALYSIS] Forecasts, Opportunities, and Challenges for the Polish Industry in 2024 [ANALYSIS]](https://industryinsider.eu/wp-content/uploads/xIndustry-40-320x167.jpg.pagespeed.ic.o8zijDQlIJ.jpg)