Broadly speaking, the robotization and automation of industrial processes is an integral part of Industry 4.0. SIEMENS Digital Industries Software (SDIS) produces a wide range of software that supports robotisation processes, from the design of nests, lines and entire production halls, through the programming of robot and CNC machine movements, to optimisation processes and flow analysis.

What is NX CAD Line Designer used for?

NX Line Designer is used to create a 3D design of a production line. It allows the creation of concepts, visualisations and documentation of lines within the NX CAD environment, an efficient environment that allows you to work on thousands of objects. The design is created with a division into real objects (departments, individual buildings, halls), production lines, nests, workstations, etc. The programme has an extensive library of machines, tools and equipment integrated into the TEAMCENTER database.

Line designing in NX Line Designer ⬇⬇⬇

What is TECNOMATIX?

TECNOMATIX enables the simulation and optimisation of production systems and processes on production lines.

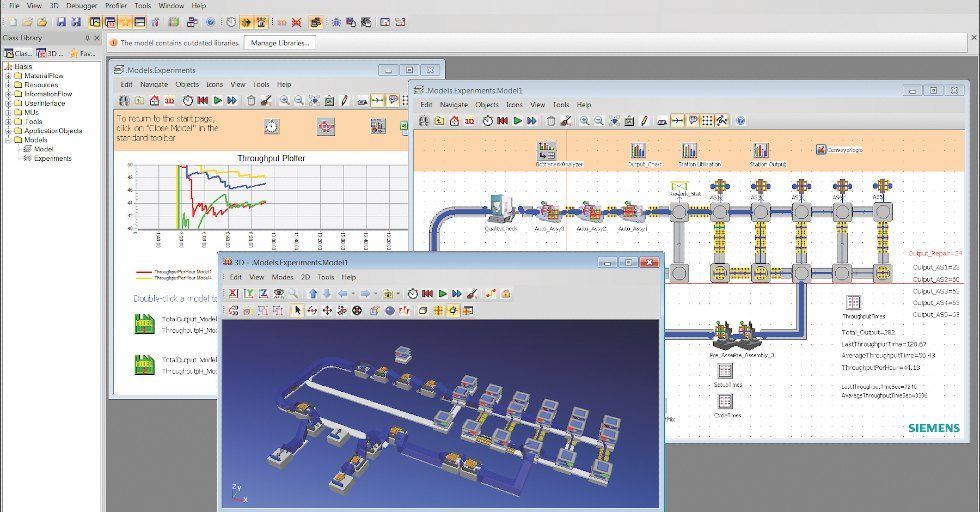

The TECNOMATIX PLANT SIMULATION package allows the user (in both 3D and 2D environments) to optimise material flow processes, analyse resource utilisation levels and verify logistics processes at all planning stages, from global production network layouts, through local facilities, down to individual lines. The user has the ability to analyse alternative solutions without interfering with production systems or during production process planning.

Plant Simulation 2D enables users to perform a wide range of simulation studies to eliminate bottlenecks, optimise throughput and reduce in-process inventory. Various tools are available to assess the performance of production systems, including Sankey diagrams and Gantt charts.

Process simulation takes into account internal and external supply chains, production resources and business processes. Plant Simulation is equipped with a range of analytical tools that enable rapid interpretation of the results obtained from the simulation process. Users receive a wealth of information in the form of graphs and summaries showing the utilisation of machine buffers and human resources. Detailed statistics on performance parameters include line loads, non-productive time, downtime, breakdowns and a range of other efficiency indicators.

In addition to the 2D view, Plant Simulation 3D provides the ability to virtually visualise the simulated process using 3D applications. This provides a “close-up” view of the entire manufacturing process, from the entry of material into storage to its exit from the line as a finished product. Dedicated libraries and the ability to import geometric data from CAD systems enable users to create 3D models of production lines or entire plants. The resulting virtual image can serve as an attractive presentation of the facility to management, current and prospective customers, and as promotional material at trade shows or various business meetings.

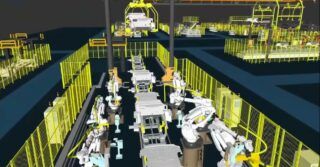

The TECNOMATIX PROCESS SIMULATE package allows you to design and simulate highly complex production areas in 3D, including production lines or workstations. It allows you to realistically reproduce the processes that take place on the production line (the work of operators, robots, tools) with precise timing. This capability facilitates process optimisation in the early stages of design, reducing costs by identifying problems early and minimising the need for physical prototypes.

Process Simulate not only enables the design of a collision-free work path for all robots across their operating areas in the production hall, but also allows them to be programmed offline. This feature significantly reduces the time required for new setups and start-ups, increasing efficiency and operational agility. Such advances in simulation technology enable manufacturers to fine-tune their production processes, anticipate potential problems before they occur and streamline the introduction of new products or changes to existing lines.

Machining cell in TECNOMATIX Process Simulate ⬇⬇⬇

What is NX CAM Robotics and what is it for?

NX CAM Robotics is one of the NX CAM modules that makes it easy to program individual industrial robots for tasks such as milling, grinding, welding or transfer. The NX CAM Robotics environment can generate code for a wide range of robots, including ABB, FANUC, KUKA, KAWASAKI, NACHI, STAUBLI and YASKAWA. It also provides realistic process simulation in a 3D environment with options for optimisation and full control, including collision detection. This capability ensures that robot programming is not only efficient but also accurate, minimising the risk of errors and maximising the productivity and flexibility of robotic applications in manufacturing.

How to use NX MECHATRONICS?

NX Mechatronics Concept Designer is a solution that facilitates the design and simulation of kinematic and physical motion sequences, as well as the virtual commissioning of machines and devices using motors, other actuators and sensors. It is an interdisciplinary application designed for systems engineering. Mechanical engineers, electrical engineers, programmers and automation experts can use it to develop and evaluate their machine concepts and quickly create alternative scenarios in a shared system environment based on customer requirements throughout the project.

Using NX Mechatronics Concept Designer, you can quickly design and evaluate the correctness of mechatronic concepts and details using product models from the CAD system. The software integrates 3D modelling with concept simulation using multi-body physics and precise automation. Instead of building expensive prototypes, it enables the simulation of machines and systems with the intended control software, allowing virtual operation. This approach not only saves time and resources, but also enhances the ability to innovate and iterate designs quickly in response to changing requirements or to optimise performance.

Mechatronics Concept Designer ⬇⬇⬇

The environments available for designing and optimising robotized halls, production lines and workstations are innovative solutions with a wide range of applications that increase the efficiency of work and the competitiveness of companies, ultimately reducing the cost of manufacturing products.

The implemented software solutions allow the user to create a complete design of the production system, together with the simulation of the processes that take place within it. This comprehensive approach allows companies to not only visualise, but also fine-tune their manufacturing processes before implementing them in the real world, ensuring that any potential issues are addressed early in the design phase, contributing to smoother operations and cost savings in the long term.

![Forecasts, Opportunities, and Challenges for the Polish Industry in 2024 [ANALYSIS] Forecasts, Opportunities, and Challenges for the Polish Industry in 2024 [ANALYSIS]](https://industryinsider.eu/wp-content/uploads/xIndustry-40-320x167.jpg.pagespeed.ic.o8zijDQlIJ.jpg)