INTRODUCTION

The primary purpose of ERP-class systems is to integrate all departments and processes in the company. Integration is based on the use of a common database within a single software system, thanks to which a company bases its operations on only one set of data. In order for the purpose of ERP to be fulfilled, the system must be provided with appropriate data. The largest amount of data comes from the area of preparing project documentation for the product manufactured in the company.

The process of preparing design documentation in almost every company is now carried out using 3D CAD software. One of the unquestionable advantages of these systems is the creation of a tree structure of products as early as at the design stage, and thus the automatic generation of BOM material lists. If, in addition, the company uses the PDM system to manage project data saved in files, then data capturing necessary to supply ERP class systems is significantly simplified.

The traditional method of transferring data from project documentation to ERP involves manually entering the data. This activity requires a significant amount of time and is associated with a high risk of errors during the operation. In companies, there are also methods based on saving bills of materials to temporary files and their later import to ERP. This method has many limitations and makes it easier to supply the system with data only to some degree.

Basing on its long-standing experience and listening to Customers’ needs, SOLIDEXPERT has prepared a solution enabling two-way data exchange between the CAD+PDM environment and ERP systems. It is a universal tool allowing constructors and technologists to work in their natural environment, which is CAD and PDM software, enabling downloading relevant data from the ERP system and sending properly formatted and validated structures of designed products to that system.

The rest of the article presents the basic functionalities of the prepared solution.

MODULE “DOWNLOAD”

In many companies, obtaining a complete Bill of Materials (BOM), in which a component is described with all the necessary features, for example, the Index of material from which it is to be manufactured, requires the use of data contained in the ERP system. In order to make it easier and faster to search for data in ERP, but above all to quickly and accurately complete the designed details with this information, the “Download” module of Multikonektor was created.

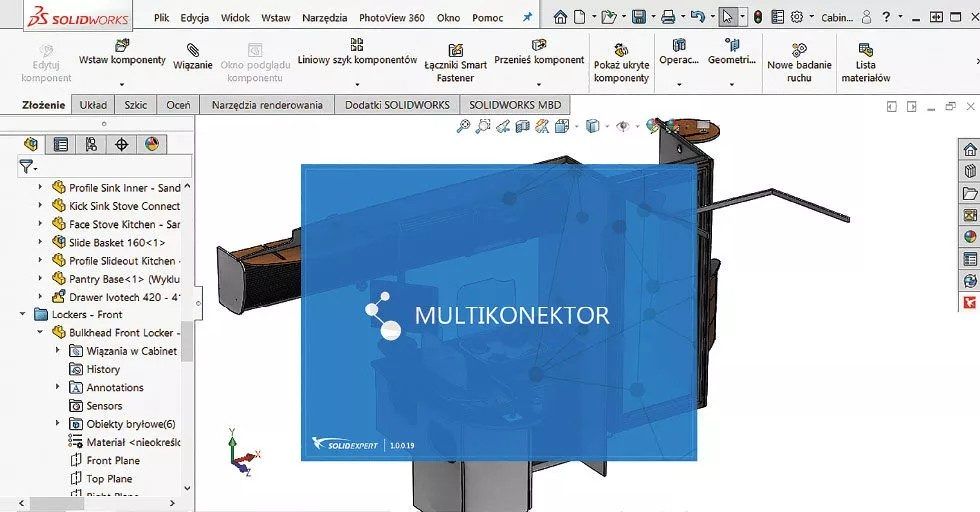

It is an extension to SOLIDWORKS embedded as one of the tabs in the SOLIDWORKS Task Window, visible on the right side of the main program window. The “Download” module is responsible for searching for index information from the ERP database and associating it with SOLIDWORKS parts and assemblies files.

The main advantages of the “Download” module:

- the ability to search for data in ERP and transfer it to designed components without leaving the designer’s work environment,

quick search for Material Indexes in ERP, - data on materials and purchase components in the construction project are the same as the data in the ERP system.

The “Download” module has also been prepared for Autodesk Inventor® to enable organizations that use different CAD solutions simultaneously or are in the process of switching to SOLIDWORKS to take full advantage of the implemented integration of the CAD+PDM environment with the ERP system.

MODULE “SEND”

The “Send” module is prepared as an extension to PDM. Settings panel of Multiconnector allows full configuration of Multiconnector operation, especially connection with ERP, mapping of Bill of Materials or permissions correlated with PDM user groups.

The “Send” module of the Multiconnector is started in the PDM file store area, through the command “Send BOM to ERP”. The running Multiconnector downloads the BOM according to the template defined in PDM and generates a preview of the product structure before sending. While building the BOM structure for export to ERP, a transformation of the “flat structure” of the construction BOM to a form representing parent – descendant relationships may take place.

Multiconnector can be configured to download the BOM calculated by PDM or to download the BOM embedded as an object in the 2D documentation of SOLIDWORKS files. In the first case, the export takes place from within the SOLIDWORKS assembly. In the second case, the BOM is exported for 2D SOLIDWORKS assembly drawings.

Data transmission to ERP can be blocked if specific correctness criteria of the BOM are not met. For the product structure loaded from PDM and subjected to transformation and validation, an error report is generated. BOM which has passed the validation is sent to appropriate structures of the ERP system. In particular, these can be transition tables, which are then processed by the ERP system.

The main advantages of the “Send” module:

- Avoiding time-consuming and error-generating manual data transcription into ERP,

- The designer does not need to use the ERP system to load it with product structure data,

- Possibility of performing automatic BOM transformations in order to optimally prepare for the creation of manufacturing BOMs (mBOM) in the ERP system,

- Possibility of validating the correctness and completeness of the BOM.

EXTENSIONS

The prepared integration solution has been designed to easily adjust it to diverse expectations of Clients. The functionalities of Multikonektor specific for individual Clients or required by non-standard processes in a given enterprise are implemented in Multikonektor by using

Extensions:

Extensions are functionalities added to Multikonektor, adding extra operations specific to the client. Examples include integration with an order system. Thanks to such a structure, the development of Multikonektor is easier and gives the client more flexibility in case of changes in the company, needs of further customisation, etc.

The main business benefits of Multikonektor are:

- Consistency of data in the ERP system and CAD+PDM

- Linking design documentation with Indexes in the ERP system

- Data validation of Bill of Materials (BOM)

- Up to 80% saving of time required for entering BOM structure into ERP

- Practically complete elimination of errors made during the manual data exchange between systems

- Improved ergonomics of the designer’s work

- Reduction of the number of ERP system client licences

SUMMARY

The integration tool developed by SOLIDEXPERT significantly shortens the time of entering product structure data into the ERP system and the transferred data are free of typical errors resulting from manual rewriting or importing by using transfer files.

The solution works as a component of the CAD+PDM environment, which further enhances its ergonomics, and its modular design allows it to be adapted to specific customer expectations.